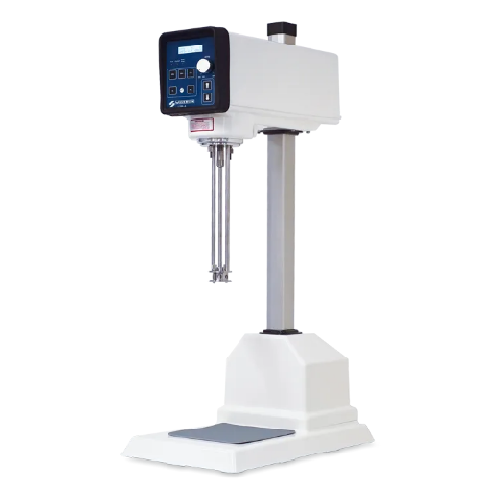

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-scale mixing operations with our high shear lab mixer, engineered to handle a wide range of materials from difficult-to-emulsify substances to viscous slurries, enabling efficient process validation and scalability.

Mixes, Emulsifies, Homogenizes, and Disintegrates

The L5M-A Laboratory Mixer from Silverson Machines stands out as a versatile high shear mixer designed for small-scale production and R&D environments. Its unique rotor/stator workhead ensures efficient mixing, emulsifying, and homogenizing, even with challenging materials like colloidal suspensions and thickeners. With capacities from 1 ml to 12 liters and in-line mixing capabilities up to 20 liters per minute, it provides scalable results for various industries, including pharmaceuticals, biopharmaceuticals, and fine chemicals. The L5M-A features a touch screen control with a digital tachometer and integral timer, which are vital for process validation and reproducibility. Constructed with 316L stainless steel wetted parts, the mixer is robust and easy to clean, facilitating compliance with GMP and FDA standards. With over 40 interchangeable workheads available, users can customize the mixing process to meet specific application needs.

Benefits

- Ensures precise and reproducible results, streamlining scale-up to full production.

- Efficiently handles diverse materials, reducing mixing time by up to 90%.

- Maintains product quality with minimized aeration during mixing.

- Facilitates rapid changeover and customization with interchangeable workheads.

- Meets stringent industry standards, ensuring compliance for pharmaceutical and food applications.

- Applications

- Polymers, Sauces, Particulate solids, Liquid formulations, Thickeners, Fine chemicals, Gels, Animal and vegetable tissues, Nutraceuticals, Rubbers, Biopharmaceuticals, Essential oils, Emulsions, Slurries, Colloidal suspensions, Dairy products, Pharmaceuticals

- End products

- Activated carbon, Silicone rubber, Latex products, Vitamin supplements, Milk protein concentrate, Meat extracts, Cough syrups, Hair gels, Cement slurries, Vaccines, Active pharmaceutical ingredients (apis), Salad dressings, Aromatherapy oils, Natural rubber emulsions, Ketchup, Fruit purees, Pain relief medication, Skin creams, Mayonnaise

- Steps before

- Material Feeding, Initial Blending, Pre-mixing, Grinding, Powder Addition

- Steps after

- Quality Control, Filling, Packaging, Sterilization, Storage

- Input ingredients

- { "input": [ "liquid materials", "solid materials", "powders", "high viscosity liquids", "fibrous materials", "elastic materials", "animal tissue", "vegetable tissue", "rubbers", "polymers", "granular solids", ], "output": [ "emulsions", "suspensions", "slurries", "gels", "thickeners", "solutions", "disintegrated solids", "hydrated powders", "homogenized mixtures", "dissolved substances", "dispersed particles", ] }

- Output ingredients

- { "input": [ "liquid materials", "solid materials", "powders", "high viscosity liquids", "fibrous materials", "elastic materials", "animal tissue", "vegetable tissue", "rubbers", "polymers", "granular solids", ], "output": [ "emulsions", "suspensions", "slurries", "gels", "thickeners", "solutions", "disintegrated solids", "hydrated powders", "homogenized mixtures", "dissolved substances", "dispersed particles", ] }

- Market info

- Silverson is renowned for manufacturing high-quality industrial mixers, specializing in high-shear mixers for industries such as food, pharmaceuticals, and cosmetics, offering customized solutions and exceptional engineering expertise.

- Speed

- Up to 10, 000 rpm

- Capacity

- 1ml up to 12 liters

- Flow rate

- Up to 20 liters/minute

- Motor power

- 1hp (750W)

- Voltage

- 110 volt / 220 volt

- Frequency

- 60 Hz

- Speed Control

- Infinitely variable electronic

- Construction material

- 316L stainless steel

- Automation

- Touch screen control

- Dimensions

- Max. Height 37 ¾ inches

- Working mechanism

- High shear rotor/stator

- Integrated steps

- Mixing, emulsifying, homogenizing, disintegrating, dissolving

- CIP/SIP

- CIP available

- Batch vs. continuous operation

- Batch and Inline

- Automation level

- Touch screen control

- Air incorporation control

- Minimized aeration through circulation pattern

- Changeover time

- Quick interchangeable workheads

- Cleaning method

- CIP

- Energy efficiency

- High efficiency operation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Mixing Functionality

- Mix, emulsify, homogenize, disintegrate and dissolve

- Capacity

- 1ml up to 12 liters

- Footprint dimensions

- Approx. 37.75” x 12.25”

- Max. height

- 20.875”

- Min. height

- 12.75”

- Control panel type

- Touch screen control with digital tachometer

- Material of construction

- 316L stainless steel

- Discharge method

- Inline with flow rates up to 20 liters/minute

- Container Compatibility

- Narrow-necked containers

- Interchangeable mixing assemblies

- Over 40 available

- Tubular mixing unit sizes

- 1", ¾", 5/8", 3/8"

- Control panel type

- Touch screen control