Commercial freeze dryer for pharmaceutical Api production

Ensure the stability and potency of your biopharmaceutical products with advanced freeze-drying, critical for maintaining the integrity of sensitive compounds like vaccines and monoclonal antibodies before sterile filling and visual inspection.

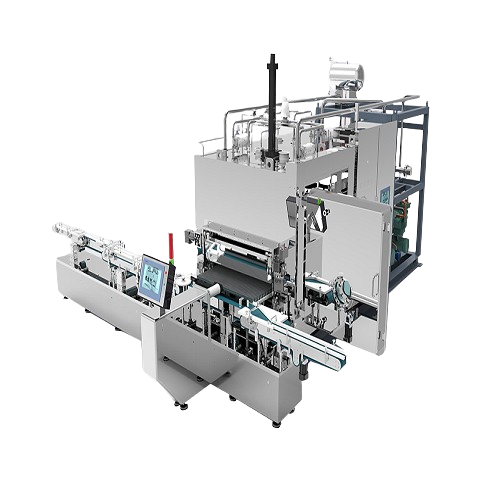

Freeze-Dries, Fills, and Inspects Pharmaceutical Products

The LYOCORE freeze-dryer from AUSTAR delivers unmatched precision in freeze-drying for pharmaceutical and biopharma applications. Designed according to European quality standards and the principles of Quality by Design (QbD), it ensures robust moisture removal from vial-packed APIs and other sensitive formulations like vaccines, monoclonal antibodies, and insulin. Capable of integrating sterile filling and visual inspection, this system enhances production line efficiency for both liquid and solid forms. With flexible configuration options and high-tech designs, it supports commercial operations while adhering to stringent cGMP and FDA compliance. Features include a sophisticated automation system for enhanced control, reduced energy usage through optimized motor control, and robust stainless steel construction for durability and chemical compatibility. Equipped with a CIP system, it ensures quick and efficient cleaning, minimizing downtime and contamination risks. Fully customizable to meet specific production needs, AUSTAR provides comprehensive engineering support for seamless integration into existing processing and final conditioning departments.

Benefits

- Enhances product integrity by ensuring precise moisture control for sensitive pharmaceuticals.

- Increases operational efficiency through seamless integration of freeze-drying, filling, and inspection processes.

- Minimizes energy costs with optimized motor control, reducing overall power consumption.

- Ensures regulatory compliance with cGMP and FDA standards, facilitating market approvals.

- Offers flexibility in production with customizable options to meet specific industry demands.

- Applications

- Biopharmaceuticals, Fine chemicals, Nutraceuticals, Pharmaceutical apis

- End products

- Vaccines, Pharmaceutical-grade amino acids, Active pharmaceutical ingredients (apis) in vial form, Insulin, Monoclonal antibodies, Vitamin supplements, Herbal extracts

- Steps before

- Purification, Drying, Grinding

- Steps after

- Sterile Filling, Visual Inspection, Packing

- Input ingredients

- vial-packed APIs, panel-packed APIs

- Output ingredients

- freeze-dried APIs

- Market info

- Austar is known for specializing in the design and manufacture of engineered-to-order industrial equipment, particularly in the pharmaceutical and biotechnology sectors, offering solutions that focus on quality, innovation, and meeting specific customer requirements.

- Automation

- PLC-controlled

- Compliance

- cGMP and FDA requirements

- Configuration

- Flexible and high-tech solutions

- Design Standard

- European quality standards

- Production Suitability

- Commercial freeze-drying of vial and panel-packed APIs

- Quality by Design

- QbD (Quality by Design)

- Batch vs. continuous operation

- Batch

- Compliance with cGMP and FDA

- Yes

- Automation level

- High/PLC

- Flexibility in solutions

- High-tech, customizable

- Cleaning method

- SIP/CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Depends on model

- Configuration

- Flexible, high-tech

- Control panel type

- Touchscreen/PLC

- Discharge method

- Automatic

- Integration possibilities

- SCADA / PLC

- Footprint customization

- Compact / Expanded

- Material options

- Stainless Steel / Others

- System capacity

- Flexible scaling

- Interface customization

- Multi-language support

- Electronic configuration

- Customizable settings