Automatic cartoning system for pharmaceuticals

Simplify your cartoning process with high-speed, continuous motion that boosts efficiency and precision for solid product packaging in pharmaceuticals, nutraceuticals, and cosmetics.

Automates Cartoning and Packaging Processes

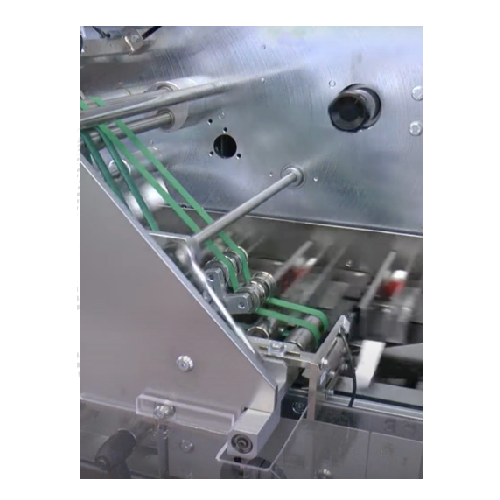

The AUTOMATIC CARTONER C-260/400 from Siempharma excels in high-speed, continuous motion cartoning applications, ideal for pharmaceutical, nutraceutical, and cosmetic sectors. What sets this machine apart is its streamlined design, featuring a cantilever structure for full accessibility and GMP-compliant operation. It operates using a sophisticated continuous motion process, including a 5-station turret for precise carton erection and suctions for reliable carton opening.

Applications range from tablet blister cartons and syrup bottles to cosmetic cream tubes and perfume boxes, ensuring versatility. With its motorized conveyor belt and product feeders tailored to various solid product types, the C-260/400 facilitates seamless integration into existing packaging lines, offering efficient product feeding, transport, and introduction across a wide spectrum of end products.

Engineered for optimal performance, the machine ensures size changes via a mechanical memory system, which minimizes downtime to under ten minutes without requiring skilled technicians, thus synchronizing production changeovers efficiently. Integrated with a user-friendly touch screen HMI, the cartoner supports fast, intuitive operation, standardized to Industry 4.0 for advanced data handling and process monitoring.

To match industry and regulatory standards, the C-260/400 is CFR21 Part 11 and EU Annex 11 ready, adhering to CE regulations. Its design supports straightforward cleaning and maintenance, underpinned by ergonomic considerations, facilitating compliance with stringent hygienic standards at all times.

Benefits

- Enhances production efficiency with rapid, tool-free size changeovers in under ten minutes.

- Reduces labor requirements and potential errors through intuitive touch screen HMI and automated functions.

- Ensures regulatory compliance with GMP standards, CFR21 Part 11, and EU Annex 11 readiness.

- Facilitates seamless integration into existing lines with adaptive feeder and transport systems.

- Minimizes contamination risks and maintenance downtime through accessible design and straightforward cleaning protocol.

- Applications

- Nutraceuticals, Cosmetics, Pharmaceuticals

- End products

- Tablet blister cartons, Perfume boxes, Vitamin supplement cartons, Protein powder packs, Skincare product packaging, Blister packs, Cosmetic cream tubes, Syrup bottles

- Steps before

- Product preparation, Carton loading, Product feeding

- Steps after

- Inspection, Packing, Quality control

- Input ingredients

- empty cartons, product feeders, leaflets, booklets

- Output ingredients

- sealed cartons, packaged products

- Market info

- Speed

- High-speed continuous motion

- Automation

- Servomotors controlled

- Changeover time

- Less than 10 minutes

- Control system

- Touch Screen HMI

- Compliance

- GMP norms

- Certification

- CE marking

- Industry Standard

- INDUSTRY 4.0

- Carton Feeding System

- Motorized conveyor belt

- Carton Erection System

- 5-station turret continuous motion

- Modular Construction

- Cantilever structure

- Memory System

- Mechanical memory system

- Flexibility

- User-friendly size changeover

- Working mechanism

- High-speed continuous motion

- Changeover time

- Less than 10 minutes

- Automation level

- PLC / Servomotor controlled

- User interface

- Touch Screen HMI

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy manual cleaning

- Compliance standards

- GMP, CE, INDUSTRY 4.0

- Footprint

- Compact and linear

- Carton Feeding System

- Motorized conveyor belt

- Product Transport

- Cam profile moving buckets

- Carton Erection System

- Continuous motion 5-station turret

- Product Introduction System

- Pusher upper blades with differentiated stroke

- Closure System

- Continuous motion closure

- Control panel type

- Touch Screen HMI

- Size changeover system

- Servomotors with mechanical memory system

- User interface

- User-friendly and intuitive

- Integration with automation standards

- INDUSTRY 4.0 compliant