Stick pack packaging line for pharmaceuticals

Optimize your pharmaceutical production with stick pack packaging lines that enhance efficiency by integrating packing, cartoning, and serialization seamlessly. Ideal for handling diverse products from effervescent tablets to liquid sachets.

Packs, Cartons, and Labels Pharmaceutical Products

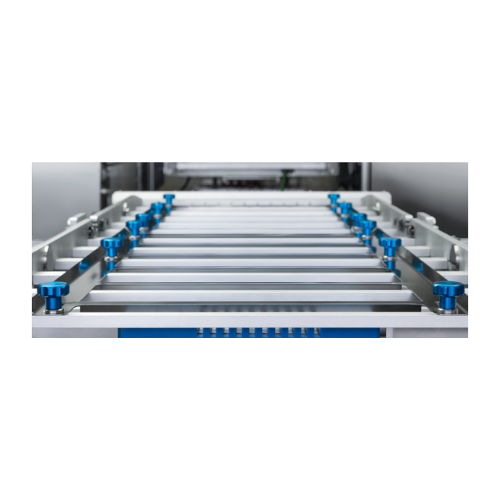

Universal Pack offers a highly specialized Pharmaceutical Stick Pack Packaging and Cartoning System, renowned for its precise integration of stick pack production and efficient cartoning. This system manages the complete process from packing to labeling, supporting various product types including powders, granules, and viscous liquids. It incorporates a counting and stacking unit that seamlessly transfers stick packs to either pre-glued or flat blank cartons, ensuring versatility in packaging formats. The system is capable of continuous, high-speed operations, enhancing throughput while maintaining product integrity through precision dosing systems tailored for different product consistencies. Universal Pack’s equipment is engineered to integrate smoothly into existing production lines, with options for third-party machinery integration, offering flexibility and scalability. With compliance to GMP guidelines, the system assures adherence to industry standards. Moreover, it includes a comprehensive track and trace module to support serialization and aggregation for product security and regulatory adherence. Designed for user-friendliness, this equipment requires minimal operator intervention, supported by a modular format change capability and efficient cleaning and maintenance features.

Benefits

- Enhances production efficiency by integrating packing, counting, and cartoning in a single automated system.

- Reduces labor costs through user-friendly design requiring only one operator for the entire line.

- Ensures regulatory compliance with integrated serialization and aggregation capabilities.

- Offers flexible packaging options, accommodating various product types and carton configurations.

- Streamlines maintenance and cleaning, minimizing downtime and maximizing operational uptime.

- Applications

- Supplements, Pharmaceuticals, Nutraceuticals, Granules, Viscous products, Tablets, Powders, Liquids

- End products

- Herbal extract stick packs, Multivitamin gummies, Vitamin stick packs, Protein powder stick packs, Probiotic sachets, Amino acid tablets, Liquid cough syrup sachets, Powdered dietary supplements, Collagen granule packs, Effervescent tablets, Rehydration solutions, Fish oil soft gel capsules

- Steps before

- Formulation, Mixing, Blending

- Steps after

- Cartoning, Leaflet Insertion, Tamper Evident Labeling, Serialization, Aggregation

- Input ingredients

- granules, powders, liquids, semiliquids, viscous products

- Output ingredients

- stick packs, cartons, pillow stick packs, side fin stick packs, shaped stick packs

- Market info

- Universal Pack is known for designing and manufacturing high-quality, customized packaging machines, specializing in sachet and stick pack technology for various industries, renowned for reliability, innovation, and exceptional customer support.

- Automation

- Single operator

- Stick Pack Type

- Pillow, side fin, shaped

- Dosing System

- Auger, basculating, gravimetric, flowmeter, piston pump

- Precision

- High levels

- Flexibility

- Total count flexibility

- Carton Type

- Pre-glued, flat blank

- Loading Method

- Side loading, top loading

- Integration

- Primary with cartoning machine, third-party machinery

- Secondary Packaging Method

- Multi-level cartoning

- Leaflet Positioning

- Exclusive

- Checkweighing

- Multi-lane

- Dosing Unit

- Removable

- Automation level

- Single operator

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Modular format change without tools

- CIP/SIP

- Not specified

- Likely manual due to user-friendly design

- Cleaning method

- Not specified

- Likely manual due to user-friendly design

- Integration capacity

- Customizable

- Integrates third-party machinery

- Energy efficiency

- Not specified

- Flexibility

- Total flexibility in counts

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- User-friendly

- Discharge method

- Top loading / Side loading

- Compact footprint

- High efficiency integration

- Customization options

- Multi-level cartoning

- Control panel type

- PLC / HMI

- Integration possibilities

- Third-party machinery compatibility

- Stick pack position

- Customizable, including on edge placement

- Counting and stacking options

- Patented systems, fully customizable

- Cartoning flexibility

- Multi-level cartoning

- Modular format change

- Without tools

- Dosing system type

- Auger, gravimetric, piston pump

- Loading system

- Top loading / Side loading