Uv flexographic printing system for blister-lidding foils

Achieve precise and consistent single-color prints on blister-lidding foils with seamless UV curing, ideal for ensuring clarity in pharmaceutical packaging.

Prints Single-Color on Blister-Lidding Foils

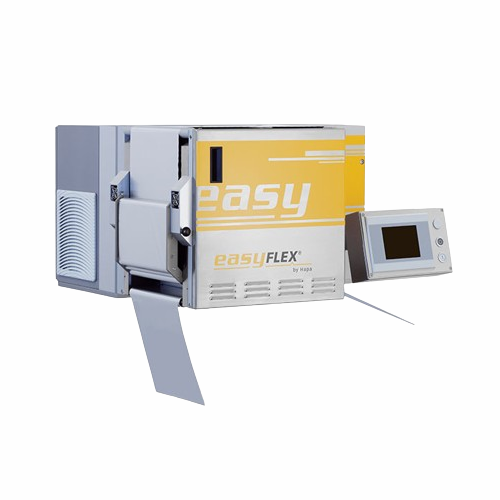

The EasyFlex 626 from HAPA is a UV flexographic printing system designed for the inline printing of single-color designs on blister-lidding foils. Featuring a solvent-free, UV-curing process, it ensures high-quality prints on materials like aluminum foil, paper, PVC, and Tyvek. Specially engineered for pharmaceutical and healthcare applications, the EasyFlex 626 seamlessly integrates into continuous and intermittent production lines, enhancing packaging efficiency for OTC drugs and nutraceuticals. With format-free operation and a quick-change inking device, it offers flexibility and minimal downtime. The integrated UV-curing unit reduces energy usage while providing instant ink curing, and optional print-mark control ensures precision. Compliance with industry standards is supported by comprehensive validation documentation.

Benefits

- Enhances production efficiency with fast, single-color printing capabilities.

- Decreases operational downtime through quick-change print mats and inking devices.

- Maintains high print quality using solvent-free UV inks, ensuring safety and environmental compliance.

- Supports diverse packaging needs with compatibility across various blister-lidding materials.

- Ensures precise and reliable printing with integrated print-mark control options.

- Applications

- Over-the-counter (otc) drugs, Nutraceuticals, Healthcare products, Pharmaceuticals

- End products

- Blister packs for cold and flu tablets, Blister packs for pain relief capsules, Blister packs for allergy relief tablets, Blister packs for vitamin supplements, Blister packs for aspirin tablets

- Steps before

- Material loading, Web alignment, Blister machine setup

- Steps after

- UV curing, Quality inspection, Product packaging

- Input ingredients

- aluminum foil, paper, PVC, Tyvek, paper-backed foil

- Output ingredients

- single color printed material on blister-lidding foils

- Market info

- HAPA, part of the Coesia Group, is renowned for its expertise in developing and manufacturing high-quality inline printing solutions, specifically for the pharmaceutical packaging industry, offering flexibility and customization for complex printing needs.

- Max speed

- 11 m/min

- Max advance length

- 180 mm

- Max printing width

- 260 mm

- Max printing length

- 180 mm

- Max web width

- 270 mm

- Min advance length

- 30 mm

- Min web width

- 50 mm

- Machine depth

- 855 mm

- Machine height

- 475 mm

- Machine length

- 873 mm

- Machine weight

- 230 kg

- Working mechanism

- Flexographic printing

- Integrated steps

- UV-curing unit

- Automation level

- Touch-screen panel controls

- Batch vs. continuous operation

- Continuous

- Changeover time

- <1 minute

- Print cylinder configuration

- Format-free

- Ink type

- Solvent-free UV-curing ink

- Cleaning method

- Quick-change inking device

- Compatible Substrates

- Aluminum foil, Paper-backed foil, Paper, PVC, Tyvek

- Solvent-free Printing

- Yes

- Machine depth

- 855 mm

- Machine height

- 475 mm

- Machine length

- 873 mm

- Machine weight

- 230 kg

- Max printing width

- 260 mm

- Max printing length

- 180 mm

- Max web width

- 270 mm

- Min advance length

- 30 mm

- Min web width

- 50 mm

- Control panel type

- Touch-screen panel

- Ink change system

- Quick-change inking device

- Print mat change

- Pin-fastened print mats

- Print cylinder configuration

- One print cylinder for all lengths

- UV curing system

- Integrated UV-curing unit

- Printing compatibility

- Blank or pre-printed materials