Blister thermoforming solution for pharmaceutical packaging

For high-speed blister packaging of solid dose pharmaceuticals, this integrated solution offers seamless thermoforming, sealing, and cartoning, ideal for ensuring packaging integrity and efficiency.

Thermoforms and Cartons Pharmaceutical Blister Packs

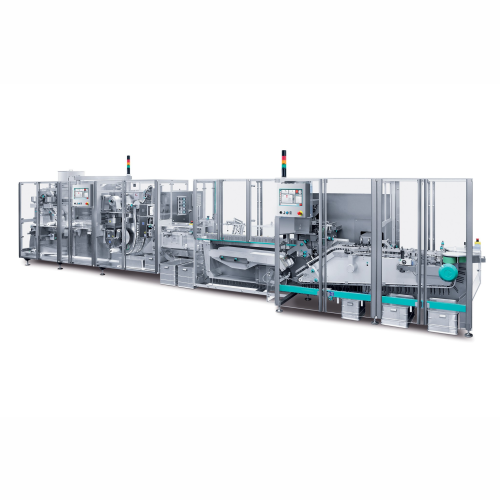

The INTEGRA 320 from Marchesini Group is a sophisticated blister thermoforming and cartoning machine designed for pharmaceutical manufacturers and packaging companies. It combines a servo motor-controlled blister section with a seamlessly integrated cartoning system, enabling efficient high-speed production for solid dose products such as aspirin, ibuprofen, and vitamin supplements. Its continuous motion ensures smooth operation, while the robotized ROBOCOMBI blister feeding system enhances precision in handling. The INTEGRA 320 can process up to 320 blisters and 260 cartons per minute, with capabilities for both flat sealing and advanced splicing. Built for energy efficiency, it meets pharmaceutical industry standards, ensuring compliance and reliability. The machine’s compact footprint and configurable design allow for easy integration into existing production lines, supporting customization for specific packaging requirements.

Benefits

- Streamlines blister packaging with integrated thermoforming and cartoning functions.

- Enhances precision and reliability through servo motor control and robotic blister feeding.

- Boosts production efficiency with a throughput of up to 320 blisters and 260 cartons per minute.

- Supports flexible production lines with customizable configurations.

- Ensures compliance with stringent pharmaceutical industry standards.

- Applications

- Supplements, Solid dose pharmaceuticals, Pharmaceutical tablets, Nutraceuticals, Blister packaging

- End products

- Multivitamin blister packs, Ibuprofen tablets, Vitamin d supplements, Fish oil capsules, Aspirin tablets

- Steps before

- Product preparation, Blister raw material loading, Forming material preparation

- Steps after

- Cartoning, Packaging, Distribution

- Input ingredients

- thermoforming film, blister packaging materials, carton materials, leaflets

- Output ingredients

- formed blister packs, cartoned blister packs

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Automation

- Integrated continuous motion monoblock machine

- Blister Width

- 30 - 86 mm

- Blister Length

- 70 - 140 mm

- Forming depth

- Up to 9 mm

- Carton Width

- 35 - 90 mm

- Carton Height

- 15 - 90 mm

- Carton Length

- 75 - 150 mm

- Blisters per minute

- Up to 320

- Cartons per minute

- Up to 260

- Blister section

- Available as stand alone machine

- Servo motors

- Yes

- Splicing tables

- Two

- Cross control product-carton-leaflet

- Yes

- Lane configuration

- 1 lane (2 lanes only after technical evaluation)

- Flat sealing

- Yes

- Minimum product and materials load control

- Yes

- Working Mechanism

- Integrated continuous motion monoblock

- Blister Management

- Servo motor management with automatic grip vacuum

- Blister Handling

- 3 axis translation with robotized feeding system

- Automation Level

- Servo driven independent pushers

- Changeover Time

- Manual evaluation required

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Hidden cutter with splicing tables

- Load Control

- Minimum product and materials load control

- Cross Control

- Product-carton-leaflet synchronization

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Integrated continuous motion monoblock

- Blister size

- Width

- Carton size

- Width

- Feeder system

- ROBOCOMBI robotized blister feeding

- Control panel type

- Sophisticated with servo-driven controls

- Control panel type

- HMI

- Servo Motors

- Yes

- Integration with cartoning section

- Specially designed belt conveyor

- Customization of lanes

- 1 lane (2 lanes after evaluation)

- Blister Feeding System

- ROBOCOMBI robotized system