Plastic processing systems for high plant availability

Achieve unparalleled throughput and efficiency in your production line with a solution designed for seamless integration, ensuring optimal homogenization and precise formulation management.

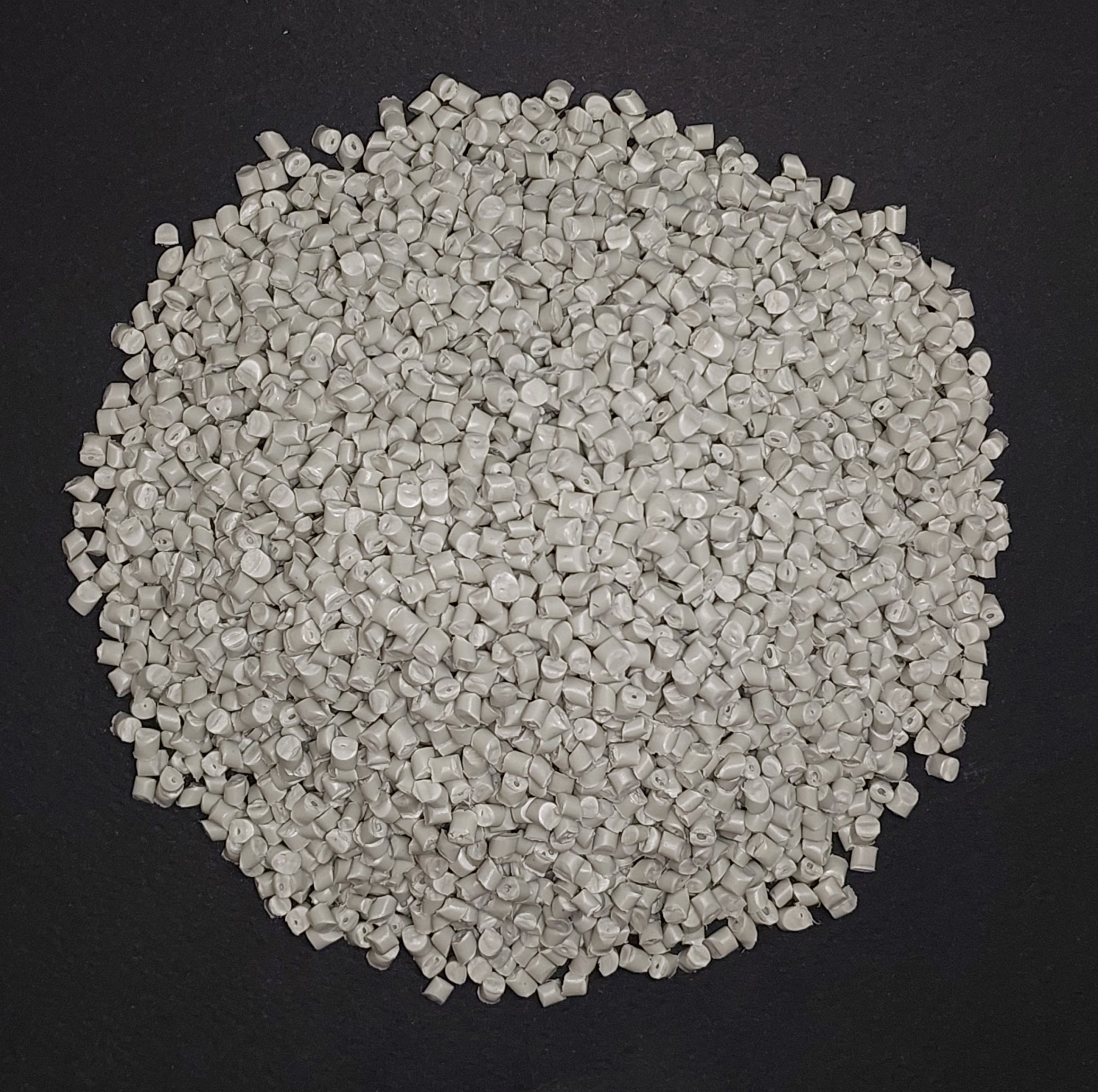

Processes and Mixes Granules and Powders

The ZSD Industrial Mixer from Zeppelin Systems GmbH is a versatile solution engineered for plastic, rubber, and food processing industries, excelling in the homogenization, coating, drying, and agglomeration of various materials. Utilizing advanced automation, it seamlessly integrates into production lines, facilitating continuous and high-speed operations. This equipment processes powders and granules like polyethylene pellets and rubber compounds, with the capability to handle rapid formulation changes and ensure high plant availability. Its design includes robust material options for chemical resistance, meeting stringent industry standards. Cleaning is streamlined through rapid cleaning features, minimizing downtime and maximizing throughput. Customizable configurations and dedicated engineering support ensure that the ZSD Industrial Mixer meets your precise operational needs, while contributing to energy efficiency with optimized motor technology.

Benefits

- Enhances production efficiency with continuous, high-speed processing.

- Minimizes downtime through rapid cleaning capabilities.

- Increases operational flexibility with customizable configuration options.

- Boosts material compatibility and longevity with corrosion-resistant materials.

- Optimizes energy consumption with advanced motor control technology.

- Applications

- Plastic processing, Performance materials, Food industry, Plastics, Rubber and tire industry, Dispersion paints

- End products

- Polyethylene pellets, Nutraceutical powders, Epoxy resins, Rubber compounds, Polypropylene granules, Emulsion paints, Vulcanized tire mixtures, Advanced composites, Thermoplastic resins, Packaged snacks

- Steps before

- Raw material preparation, Plastic melting, Initial mixing

- Steps after

- Packaging, Quality control, Distribution

- Input ingredients

- plastic formulations, individual formulation components

- Output ingredients

- homogenized plastic, coated plastic, dried plastic, agglomerated plastic

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Capacity

- Large throughputs

- Plant Availability

- High

- Automation

- Process Control

- Conveying Process

- Gentle

- Cleaning Method

- Rapid cleaning

- Batch vs. continuous operation

- High plant availability with large throughputs

- Automation level

- Integrated with process control and SCADA systems

- CIP/SIP

- Rapid cleaning options for formulation changes

- Changeover time

- Minimized through quick cleaning processes

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Customizable

- Control panel type

- Touchscreen HMI/PLC

- Integration possibilities

- SCADA/ERP integration

- Modular design

- Available

- Capacity customization

- Adjustable throughput

- Mixing configuration

- Customizable

- Interface options

- Customizable interface schemes