Rotary vacuum paddle dryer for pharmaceutical ingredients

Ensure precise moisture control and efficient drying for sensitive compounds, optimizing your production line for high-quality chemical and pharmaceutical outputs.

Dries, Mills, and Mixes Sensitive Ingredients

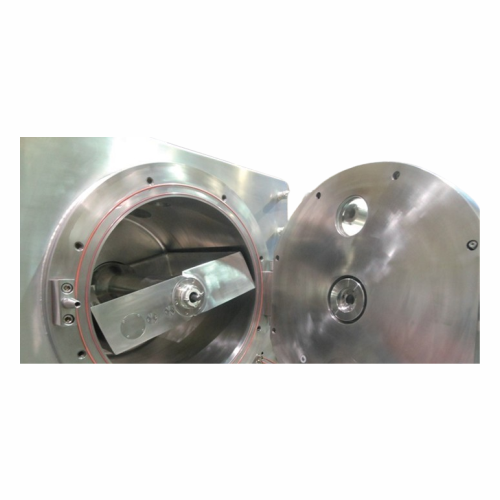

The MAVADRY from GMM Pfaudler is a rotary vacuum paddle dryer specifically designed for pharmaceutical and chemical processing. It utilizes a heated airfoil blade with an integrated high-speed chopper, ensuring efficient drying and mixing of sensitive ingredients. With its high-torque hydraulic drive, the MAVADRY accommodates a wide range of filling capacities, making it ideal for producing active pharmaceutical ingredients, specialty fine chemicals, and biopharmaceuticals.

Operating under batch mode, it achieves precise moisture control and uniform drying through minimal clearance between the vessel wall and agitator, along with complete jacket coverage for enhanced heat transfer. The MAVADRY’s versatile design supports wet or dry chopping in combination with stator-assisted milling, enhancing particle size reduction and consistency.

Available in stainless steel, Hastelloy, and special alloys, it meets stringent cGMP and FDA guidelines, ensuring compatibility with sensitive applications. Maintenance is simplified with a hinged front door for easy access and inspection, while its compliance with pharmaceutical standards ensures reliability and safety in purification and final conditioning processes.

Benefits

- Enhances product quality with consistent and uniform drying.

- Boosts operational efficiency by accommodating a wide range of filling capacities.

- Reduces maintenance time through easy access via hinged front door.

- Ensures process safety and compliance with cGMP and FDA standards.

- Minimizes particle size variance with integrated high-speed chopping and milling.

- Applications

- Chemical formulations, Fine chemicals, Nutraceuticals, Biopharmaceuticals, Pharmaceutical ingredients

- End products

- Active pharmaceutical ingredients (apis), Monoclonal antibodies, Vitamin supplements, Chemical excipients, Specialty fine chemicals

- Steps before

- Filtration, Wet milling, Solid-liquid extraction

- Steps after

- Sterilization, Packing, Coating

- Input ingredients

- freely flowing pharmaceutical ingredients, sensitive pharmaceutical ingredients, fine chemicals

- Output ingredients

- dried pharmaceutical ingredients, dried fine chemicals

- Market info

- GMM Pfaudler is known for manufacturing glass-lined equipment, reactors, and engineered-to-order (ETO) solutions for the chemical, pharmaceutical, and allied industries, recognized for their innovation, quality, and global presence.

- Capacity

- 100–4000 L

- Material

- Stainless Steel / Hastelloy / Special Alloys

- Drive

- High-torque hydraulic drive

- Design Compliance

- cGMP and FDA guidelines

- Clearance

- Minimal clearance between vessel wall and agitator

- Heat Transfer

- Whole vessel covered by jacket

- Chopper Type

- Integrated high-speed chopper

- Filling Flexibility

- High degree of filling flexibility

- Access

- Hinged front door for easy inspection

- Working mechanism

- Rotary vacuum paddle dryer

- Integrated steps

- Wet or dry chopping with milling

- Batch vs. continuous operation

- Batch

- Automation level

- High-torque hydraulic drive

- Cleaning method

- Hinged front door for easy access

- Energy efficiency

- High performance drying

- Compliance with regulations

- cGMP and FDA guidelines

- Corrosive resistance (e.g. acids)

- Stainless Steel, Hastelloy, Special Alloys

- Biological compatibility

- cGMP and FDA compliance

- Discharge method

- Hinged front door for easy access or inspection

- Tank shape and size

- 100 to 4000 litres

- Material

- Stainless steel, Hastelloy, special alloys

- Material Options

- Stainless steel / Hastelloy / Special alloys

- Capacity Range

- 100 to 4000 litres

- Hinged Front Door

- Yes

- Hydraulic Drive

- High-torque