In-line printing and verification for cartons

Optimize your packaging line with seamless printing, verification, and sealing capabilities, ensuring accurate labeling and tamper evidence on up to three sides of various carton formats efficiently.

Prints, Verifies, Weighs, Labels, and Seals Cartons

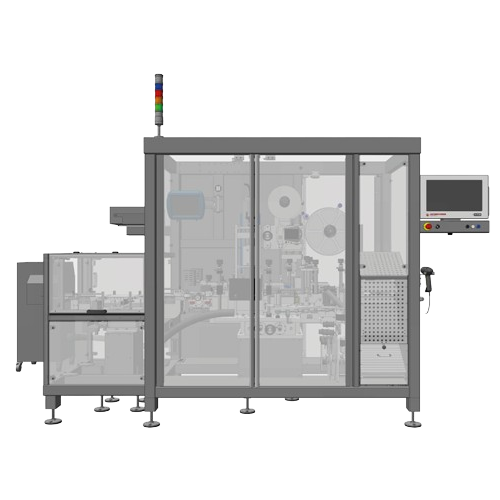

The Print & Check Flex (3600) from Antares Vision Group is a sophisticated printing and verification system designed to meet the diverse needs of pharmaceutical and packaging companies. This system offers unparalleled flexibility and precision in handling various carton sizes and formats. It features combined laser and inkjet printing capabilities that ensure accurate data and code verification on up to three sides of a carton. The built-in checkweigher and integrated labeling unit guarantee high-speed, tamper-evident sealing and labeling accuracy. Operating at speeds up to 400 pcs/min, this system supports seamless in-line or standalone operation with customizable belt pitches and carton sizes for optimal throughput. The P&C Flex is ideal for producing blister packs, cosmetic cartons, vitamin bottles, and more, ensuring compliance with industry standards through rigorous track & trace inspection and grading. Additionally, the system is equipped with a user-friendly HMI for integrated management and optional thermal transfer print capability, emphasizing ease of use and operational efficiency.

Benefits

- Enhances production efficiency with seamless integration into existing lines.

- Minimizes packaging errors with precise code verification and tamper-evident sealing.

- Versatile operation accommodates a wide range of carton sizes and formats.

- Increases throughput with high-speed processing up to 400 pcs/min.

- Ensures compliance with industry standards through comprehensive track & trace capabilities.

- Applications

- Life science products, Nutraceuticals, Cosmetics, Food packaging, Pharmaceuticals

- End products

- Vitamin supplement bottles, Blister packs for tablets, Cosmetic cream cartons, Laboratory test kit cartons, Packaged snack boxes

- Steps before

- Cartoning preparation, Material sorting

- Steps after

- Carton sealing, Packing, Distribution

- Input ingredients

- cartons, labels, ink cartridges, tamper-evident seals

- Output ingredients

- printed cartons, checked cartons, labeled cartons, verified and tamper-sealed cartons

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- Up to 400 pcs/min (300 pcs/min with checkweigher)

- Working Height

- 800-1000 mm

- Standard Belt Pitch

- 160, 220, 320 mm

- Carton Size (mm)

- A = 35-280 / B = 15-130 / C = 45-250

- Printing Technology

- Laser and TIJ (Thermal Inkjet) 2.5

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical

- Up to grade A

- N. of Cameras for Track,Trace Inspection

- Up to 4

- Standard Controls

- 1D/2D code recognition, print quality grade evaluation, OCV/OCR

- Label Width (Top Labelling)

- Up to 60 mm

- External Roll Diameter (Top Labelling)

- Up to 300 mm (400 mm optional)

- Label Width (Tamper Evident)

- Up to 40 mm

- Label Length (Tamper Evident)

- Up to 30 mm

- Gap Between Labels

- 3 mm

- External Roll Diameter (Tamper Evident)

- 280 mm

- Standard Deviation 1σ (Checkweigher)

- 0.15 g

- Max Carton Weight

- 500 g

- Printing positions

- Up to 3 sides

- Changeover flexibility

- High

- Integrated steps

- Printing, checking, labeling, sealing

- Automation level

- Single HMI controlled

- Batch vs. continuous operation

- Inline continuous

- Line speed

- up to 400 pcs/min

- Abrasion resistance

- High

- Biological compatibility

- Pharma grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Resistant to mild acids

- Density/particle size

- Accommodates small to large cartons

- CE marking

- Yes

- Machine footprint dimensions

- N/A

- Standard Carton Size

- A = 35-280 mm, B = 15-130 mm, C = 45-250 mm

- Working Height

- 800-1000 mm

- Belt Pitch

- 160, 220, 320 mm

- HMI Type

- Single HMI to manage settings

- Control panel type

- Single HMI

- Integration possibilities

- Laser and inkjet capability

- Label application options

- Top and bottom, same side or alternated

- Printing system

- Laser, Inkjet, TIJ 2.5

- Print sides

- Up to 3 carton sides

- Optional integrations

- Thermal transfer print engine