Essential oil extraction from citrus fruit peel

Optimize your citrus fruit essential oil extraction process with a versatile system designed to enhance oil separation, recovery, and purity while maintaining the integrity of the natural fruit peel.

Extracts Essential Oils from Citrus Peels

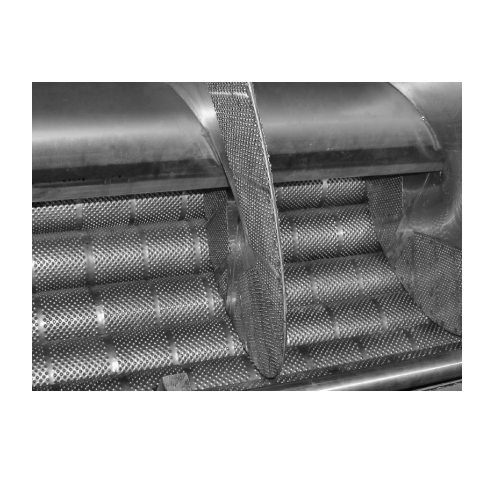

The Zumex ET6 Oil Extractor is engineered by Zumex Food Engineering for food processing and citrus product manufacturers needing efficient essential oil extraction from citrus peels. This extractor employs an abrasive roller system combined with a dual water aspersion line to effectively scrape and recover citrus oils. Suitable for producing lemon, orange, grapefruit, and lime essential oils, as well as citrus juice concentrates and zest oils, the ET6 supports continuous, high-speed operations. With adjustable roller speeds and an abrasive peeler, it optimizes the extraction process. Made from AISI 304 stainless steel, it offers IP65 protection, ensuring reliability and durability. Integrated features such as a centralized greasing system, easy-to-access emulsion intake hopper, and removable cleaning components simplify maintenance. The ET6 aligns seamlessly into existing product lines, featuring a centralized electric control panel for operational efficiency and safety, complete with emergency stop functions.

Benefits

- Enhances production efficiency with customizable extraction speeds.

- Minimizes maintenance time with easy-to-clean components and centralized greasing.

- Ensures operator safety with built-in emergency stops and protective access features.

- Preserves oil quality through precise, abrasive roller technology.

- Seamlessly integrates into existing production lines for streamlined operations.

- Applications

- Fruit processing, Food processing equipment, Juice extraction, Citrus fruit oil, Essential oils

- End products

- Citrus juice concentrates, Zest oils, Orange essential oil, Citrus peel extracts, Lemon essential oil, Grapefruit essential oil, Lime essential oil, Cold-pressed citrus oils, Fruit puree bases, Citrus-infused beverages

- Steps before

- Selection, Washing, Drying, Calibrating

- Steps after

- Oil recovery, Oil-water emulsion separation, Filling, Packing, Bottling, Labeling

- Input ingredients

- whole fruit peel, fresh fruit rind, citrus fruit

- Output ingredients

- essential oils, essential citrus fruit oil, oil-water emulsion

- Market info

- Extraction System

- Abrasive roller system

- Roller Configuration

- Perforated rollers with variable rotation

- Speed Control

- Adjustable roller and fruit movement speed

- Scraping Degree

- Variable by regulating machine speed

- Water Aspersion Line

- Dual system for oil extraction

- Material of Control Panel

- AISI 304 stainless steel

- IP Protection

- IP65

- Safety Features

- Inspection windows and safety detectors

- Emergency Stop

- Two pushbuttons on frame and panel

- Maintenance System

- Centralised greasing system

- Cleaning Features

- Removable hopper and side access doors

- Working mechanism

- Abrasive roller system

- Integrated steps

- Extraction, emulsion recovery

- Batch vs. inline operation

- Batch

- Scraping degree control

- Adjustable

- Safety inspection

- Windows, doors with detectors

- Abrasion resistance

- AISI 304 stainless steel

- Cleanability

- Easy-to-clean design

- Corrosive resistance (e.g. acids)

- AISI 304 stainless steel

- Compact footprint

- Machine dimensions not specified

- Roller type

- Abrasive perforated rollers

- Feed method

- Whole and fresh fruit peel or rind

- Discharge method

- Not explicitly stated

- Control panel type

- Electric control panel made of AISI 304 stainless steel

- Adjustable Roller and Fruit Movement Speed

- Yes

- Control Panel Material

- AISI 304 Stainless Steel

- Protection Level

- IP65

- Emergency Stop Pushbuttons

- 2 (One on Machine Frame, One on Control Panel)