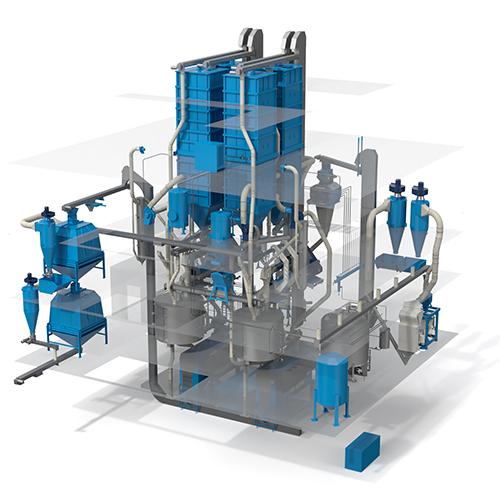

Organic soybean oil pressing plant

Soybean oilseeds are usually processed through extraction methods using hexane or other solvents to produce soybean oil. To ensure the quality of soybean oil and meal, chemical solvents need to be separated and removed. However, organically grown soybeans need to avoid using oil extraction solvents to produce ecological products. You thus need a mechanical system of pressing and extrusion to maximize oil yield and improve the quality of press cake.

Hexane-free pressing and extrusion solution for high-quality oil and feed production

Farmet’s soybean pressing plant combines mechanical and thermal processing to help you obtain maximum oil yield. It provides you with a combination of extrusion and subsequent oil pressing, which enables you to yield high quality press cake and oil. This is achieved by heating of the grinded seeds during extrusion, which makes pressing easy and also leads to minimal leftover fat.

Once the seed enters the plant, it is cleaned and destoned in the seed pre-treatment unit before being ready to be crushed and extruded. Farmet’s soybean extruder contributes to reducing the amount of anti-nutritional substances and increasing bypass protein during soybean meal production. Subsequently, the extruded soybean seeds enter Farmet’s expeller oil press. The organic soybean oil pressing plant has a capacity ranging from 6 to 600 tons of seeds per day.

Benefits

- Free of chemical solvents like hexane

- Cost efficient and environment friendly

- Suitable for processing organically-grown and ecological products