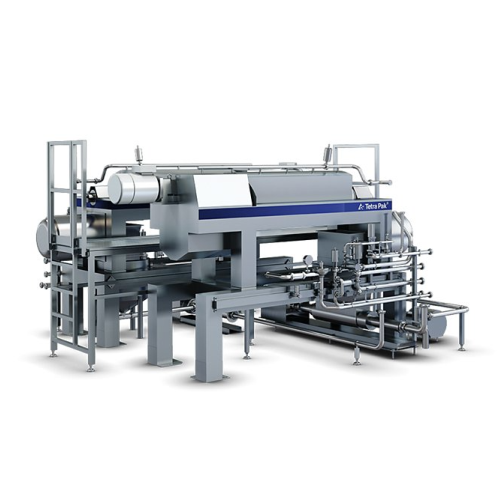

Double decanter for plant-based beverage extraction

Maximize protein yield and enhance extraction efficiency in your plant-based beverage production with this high-speed solution, ensuring optimal separation and decanting of liquid and solid components.

Efficiently Extracts and Separates Plant-Based Liquids

The Tetra Pak® Double Decanter is a robust solution for separating and extracting plant-based beverage components. Utilizing a differential speed technology, it optimizes yield and quality by adjusting sedimentation levels. Ideal for plant-based milks like oat, almond, and soy, it operates continuously at high speeds, processing up to 8,000 kg per hour. The decanter’s hygienic design incorporates CIP cleaning devices and SaniRibs® for superior cleanability, minimizing bacterial growth risks and ensuring high performance. It features a pressurized discharge system that maintains product integrity by reducing air integration and foam during formulation. The decanter is fully automated and integrates effortlessly with existing production lines, offering control through PLC systems. Its industrial-grade construction ensures durability and low maintenance in demanding food and beverage applications.

Benefits

- Enhances production efficiency with high-speed, continuous operation.

- Maintains product quality by minimizing air integration and preventing oxidation.

- Reduces cleaning time and contamination risk with CIP and hygienic design.

- Increases yield with adjustable sedimentation and differential speed control.

- Integrates seamlessly into existing lines with automated, PLC-controlled systems.

- Applications

- Plant-based beverages, Oat beverages

- End products

- Coconut milk, Oat milk, Almond milk, Soy milk, Rice milk, Cashew milk

- Steps before

- Grinding, Hydrolysis, Thermal Deactivation

- Steps after

- Foam Minimization, Oxidation Prevention, Powder Incorporation

- Input ingredients

- plant-based raw materials, suspended solids, oat

- Output ingredients

- smooth liquid product base, plant-based beverages, oat beverages, protein yield

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 4, 000 or 8, 000 kg per hour

- Differential speed

- 2-7 rpm

- Cleaning method

- CIP (Cleaning-in-place) spray balls

- Batch vs. continuous operation

- Batch / Inline Continuous

- Hygienic design

- Cleaning-in-place (CIP)

- Automation level

- Manual / PLC / SCADA

- Air incorporation control

- Minimal air incorporation

- Pressurised discharge

- Secures food safety and quality

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Foaming

- Minimized through pressurised discharge

- Machine footprint

- Compact design

- Discharge method

- Pressurised discharge

- Cone shape

- Screw conveyor and bowl

- Bowl speed difference

- 2-7 rpm

- Discharge method

- Pressurised

- Automation level

- PLC-controlled

- Cleaning method

- CIP