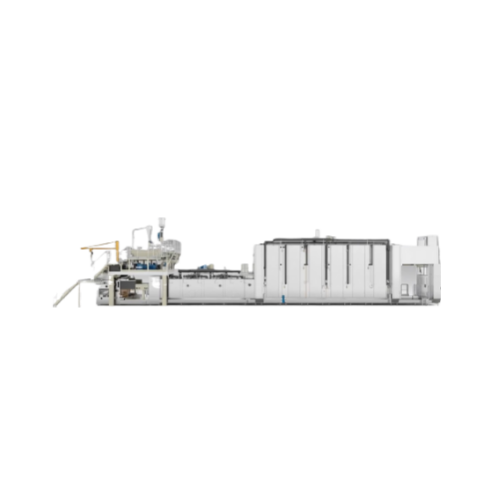

Industrial Long-cut pasta production line

Achieve superior long pasta quality with energy reductions up to 30%, featuring precise thermal and humidity controls to optimize your drying and pre-drying processes while innovatively managing line efficiency.

Dries and Controls Long-cut Pasta Production

The Long-cut Pasta Multidrive Production Line by GEA revolutionizes pasta manufacturing with its advanced Multidrive technology, offering precise control over thermo-hygrometric conditions for efficient drying. This line is specifically designed for pasta producers aiming to enhance quality and reduce energy consumption by up to 30%. Utilizing a multiple pulse ventilation system and optimized exhaust air management, it ensures superior stability and cooking quality in products like spaghetti and fettuccine. This system can process from 1 to 6 tons per hour, depending on configuration, and is seamlessly integrated with existing production setups. Its compact design reduces line length by 25%, facilitating easy access and maintenance. The equipment’s continuous high-speed operation supports complex production needs while being environmentally conscious. Customizable to various operational requirements, it offers robust engineering support for tailored solutions.

Benefits

- Enhances product quality with precise temperature and humidity control.

- Reduces energy costs by up to 30% through efficient air management.

- Minimizes production footprint by shortening line length by 25%.

- Supports high-speed continuous operation for increased productivity.

- Simplifies maintenance with easy access to critical components.

- Applications

- Snacks, Pasta, Long-cut pasta, Breakfast cereals, Dry pasta

- End products

- Spaghetti, Fettuccine, Vermicelli, Pappardelle, Tagliatelle, Linguine

- Steps before

- Mixing, Kneading, Extrusion

- Steps after

- Cooling, Packaging, Quality Inspection

- Input ingredients

- semolina, water

- Output ingredients

- long-cut pasta

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Energy Saving

- Up to 30%

- Throughput (Mono tier)

- 1 to 2.5 tons/hour

- Throughput (3 tiers)

- 1.5 to 6 tons/hour

- Line Length Reduction

- Reduced by 25%

- Humidity Control

- Accurate

- Temperature Control

- Accurate

- Temperature Change Rate

- High gradients

- Ventilation System

- Multiple Pulse Ventilation

- Access to Dryer

- Easy access

- Automation level

- High, utilizing PLC/SCADA

- Energy efficiency

- Global energy saving up to 30%

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy access for maintenance

- Thermo hygrometric control

- Continuous

- Temperature and humidity control

- Highly accurate

- Pre-drying and drying process

- Optimized with Multiple Pulse Ventilation system

- Exhaust air extraction

- Optimized

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Reduced length of the line (-25%)

- Control panel type

- Advanced control for thermo hygrometric conditions

- Discharge method

- Drying and pre-drying process with optimized air extraction

- Control panel type

- Advanced HMI

- Integration possibilities

- SCADA/PLC integration

- Compact footprint

- Reduced line length by 25%