Making Rose Oil

Find innovative production technology for making rose oil and connect directly with world-leading specialists

Rose oil is an essential oil extracted from the petals of either Rosa damascena and Rosa centifolia. Also known as liquid gold, rose oil production originated from Greece and is currently manufactured mainly in Bulgaria, Turkey, and Morocco. Studies have shown that rose oil has medicinal properties, exhibiting anti-inflammatory, anti-infective, and wound healing actions.

Select your rose oil process

Tell us about your production challenge

Steps and equipment in the production of rose oil

The rose oil manufacturing process uses two methods: it happens either through classic distillation or solvent extraction. Steam distillation requires the use of a distillation still into which you add the steam and inject it into the plant material. This releases your desired oils and vaporizes them, making it possible for you to then transfer them from the distillator into the condenser. The condensate is collected in a separator, which allows the isolation of your oil from the water. This process yields rose oil and rose water, both of which have high market demand.

On the other hand, solvent extraction uses solvents such as hexane and ethanol to separate the rose oil from the plant material. The resulting product of the rose oil production is a waxy compound called a concrete, which is mixed with alcohol to release the oils. Compared to classic distillation, rose oils extraction using this option has a finer fragrance. The rose oil extraction machine setup using this method involves the use of a vacuum distiller, condenser, and a collector.

The use of solvents, however may affect how consumers view the purity of your product. Essential oils extracted by distillation and mechanical cold pressing are least changed and retain their natural properties and composition the most compared to solvent extraction.

Rose oil vs. rose water: how can you make them?

Rose oil production sources from four major species: Rosa damascena, R. alba, R. gallica, and R. centifolia, with the highest recovery and best quality produced from the first species. Cultivations of other species, such as R. alba, R. gallica, R. francofurtana, R. centifolia, and R. rugosa were explored in the past century. However, the low rose oil content and different composition of the extracted oils discouraged their cultivation on an industrial scale.

Between rose oil and rose water, the former is more expensive to produce. One ton of rose petals yields only one liter of rose oil. Rose oil is mainly known for its aromatherapeutic effect, helping uplift sad moods and sleep difficulties. In addition, rose oil has anti-inflammatory and antiseptic effects, and can act as a light pain reliever. Its unsaturated fatty acids also make it ideal for skincare by increasing blood circulation, moisturizing, and promoting anti-aging. On the other hand, rose water is a by-product of the distillation of rose oil. Unlike rose oil, you can produce these in larger quantities. Rose water is perfect for skin blemishes, blackheads, and pimples due to its anti-inflammatory properties. It can also reduce face redness, puffy eyes, and dark circles. In terms of aromatherapy, it is similar to rose oil but it has a lower potency due to a lower concentration of aromatic compounds.

Regulations binding the rose oil market

The US FDA categorizes rose oil as generally recognized as safe (GRAS) when utilized according to its intended use. If you are planning to market rose oil as a cosmetic product in Europe, your product will be subjected for compliance to EC No. 1223/2009, which covers cosmetic products. On the other hand, the Government of Canada, for instance, is still drafting its regulations for rose oil. Initial chemical risk assessment showed that this product does not cause danger to the environment and does not cause adverse health effects when eaten with food. However, they found that this is harmful to toddlers and infants when ingested, affecting their red blood cells and their spleen. In your rose oil production, never forget to label your product with its intended use to properly inform your consumers.

Processing steps involved in rose oil making

Which rose oil technology do you need?

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Bottle filling and capping monobloc

Spillage and overfilling are common problems in most production lines for bottled produ...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

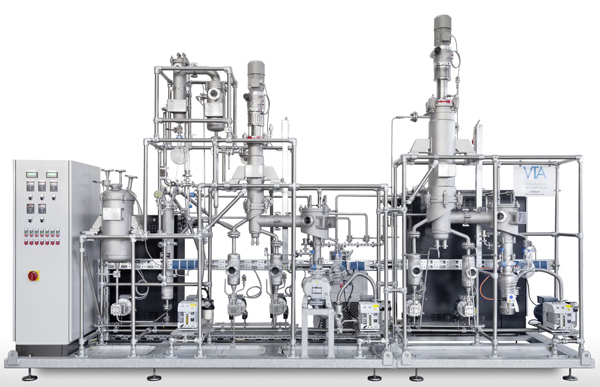

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot short path distiller

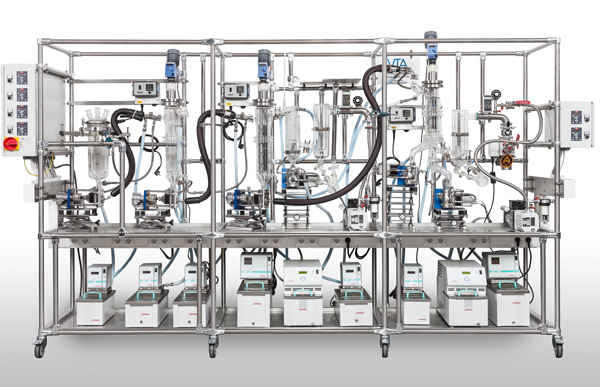

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...