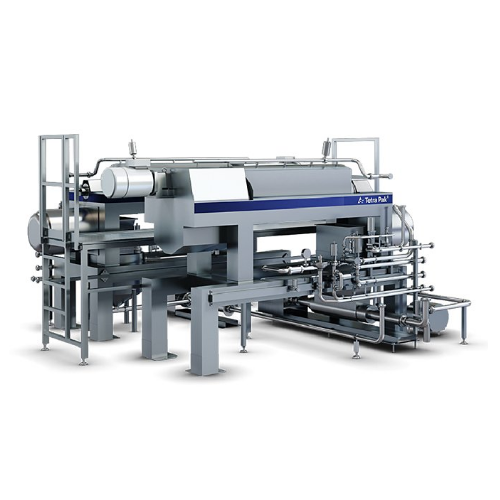

High-precision decanter for plant-based beverages

Enhance your plant-based beverage production with a decanter engineered for high-yield extraction and precise sedimentation control, ensuring top-quality milk alternates with minimal foaming.

Extracts and Separates Liquid Bases from Slurries

The Tetra Pak® Decanter is a specialized solution tailored for the plant-based beverage sector, focusing on efficient separation and extraction processes. Utilizing a differential speed mechanism, it decants liquid bases with precision, crucial for producing high-quality oat, almond, and soy milks. The unit’s throughput varies, capable of processing up to 15,000 liters per hour, making it suitable for both small-scale and high-demand operations. Its automated setup allows seamless integration into existing production lines, with PLC controls facilitating operational stability and remote diagnostics. Energy efficiency is enhanced via an optimized motor setup, reducing consumption during continuous operations. Constructed from corrosion-resistant materials, the decanter ensures longevity and compliance with food-grade standards. The unique pressurized discharge minimizes foaming, a common challenge in liquid formulations, ensuring product quality and safety. Cleaning is streamlined with a CIP (cleaning-in-place) system, incorporating SaniRibs® technology to maintain hygiene and reduce downtime. For manufacturers looking to adapt the equipment to specific needs, customization options are available, supported by engineering consultations to optimize configurations.

Benefits

- Maximizes yield with precise sedimentation control, ensuring high-quality plant-based beverages.

- Reduces operational costs through energy-efficient motor control.

- Enhances product safety by minimizing air incorporation, reducing oxidation risks.

- Facilitates maintenance with rapid CIP cleaning, minimizing downtime.

- Supports scalable production with capacities up to 15,000 liters per hour.

- Applications

- Plant-based beverages, Oat beverages

- End products

- Hazelnut milk, Coconut milk, Oat milk, Almond milk, Soy milk, Rice milk, Flax milk, Hemp milk, Pea milk, Cashew milk

- Steps before

- Grinding, Hydrolysation

- Steps after

- Sterilization, Packing

- Input ingredients

- plant-based materials, oat materials, raw materials

- Output ingredients

- plant-based beverage base, extracted liquid base, smooth slurries

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 1, 000 or 15, 000 litres per hour

- Yield

- Typically 83%

- Differential Speed

- 2–7 rpm

- Cleanability

- Cleaning-in-place (CIP)

- Design Standard

- Hygienic Design

- Discharge Pressure

- Pressurised discharge

- Yield control

- High yield – typically 83%

- Foam control

- Low foaming with pressurised discharge

- Cleaning method

- CIP cleaning devices, spray balls

- Automation level

- Fully automated with differential speed control

- Bowl speed difference

- 2-7 rpm

- Sedimentation control

- Adjustable through differential speed

- Hygienic design

- Includes SaniRibs® for maximum cleanliness

- Cleanability

- High (with CIP cleaning devices)

- Density/particle size

- Low sedimentation in extracted base

- Agglomeration risk

- Low

- Food safety compliance

- High

- Tank size

- 1, 000 or 15, 000 litres per hour

- Feed/discharge method

- Pressurised discharge

- Discharge method

- Pressurised discharge

- Control panel type

- Touchscreen HMI