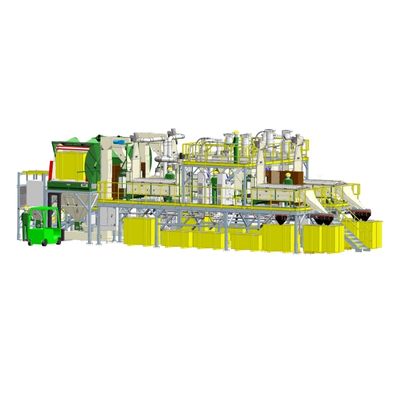

Automatic processing line for field crop seeds

The quality of field crops (ROW crops) is determined by their seeds. The breeding and foundational phases are critical for viable lots, but accuracy comes at the expense of time efficiency. The multi-stage process raises the risks of contamination and leads to seed wastage.

Increase yield and accuracy with an automatic end-to-end line

Seed Processing Holland developed specialized Automated Processing Lines (APL) for field crops (ROW crops) that maintain quality and turnout. The closed system takes the seeds from threshing/shelling through cleaning and treating.

Designed for specific crops, the technology handles most crops, including sugar beet, corn (maize), and oil rape seed. The hardware is built to accommodate the particular dimensions and structure of lots, ensuring their proper treatment throughout the line.

Besides the integrated machines, the APL is powered by SPH Connect®, simplifying complex processes into pre-programmed recipes. Thanks to combined equipment and process data, growers and seed producers can set their quality parameters and adhere to them lot after lot.

The automatic internal cleaning feature provides a contamination-free CIP solution. Moreover, the units are purposefully designed to facilitate flow and prevent seed contamination by avoiding seed mixing between lots.

Benefits

- Gentle threshing systems

- Multiple separation techniques (shape, weight, color, etc.)

- Rotary seed coating and pelleting

- SMART processing programming