Vibrating calibration system for accurate seed sieving

Optimize seed processing with an advanced vibrating calibration system, designed to streamline sizing and sorting operations. Perfect for handling granular materials efficiently, it simplifies the separation process across multiple fractions, enhancing productivity while maintaining precision in your sieving operations.

Calibrates and Sieves Diverse Seed Materials

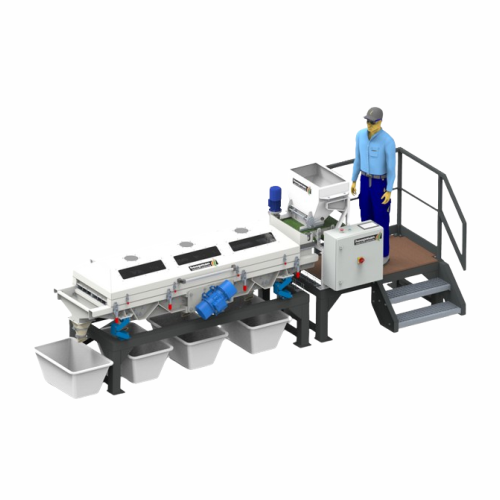

The VCS600 Vibrating Calibration System from Hoopman Equipment & Engineering is a plug-and-play solution specifically engineered for seed processing and agribusiness challenges. Featuring an innovative sieve clamping system, it allows seamless sieve changes without tools, enhancing operational efficiency. Capable of managing up to 10 fractions in a single run, it excels in applications such as vegetable, grain, and grass seed calibration. Designed to handle both lab-scale and high-volume operations, the VCS600 integrates seamlessly into existing production lines, ensuring consistent and precise sorting of granular materials. It includes a dust and noise hood, and a control box for optimal operation. The system’s no-tool access ensures quick inspections and maintenance, reducing downtime and costs. Built with scalability in mind, the VCS600 adapts to various throughput requirements and supports customization to meet specific processing needs.

Benefits

- Enhances processing efficiency with quick, tool-free sieve changes.

- Increases sorting precision with up to 10 fractions in a single operation.

- Minimizes operational noise and dust exposure with integrated hood.

- Adapts to varying production scales, from lab experiments to high volume outputs.

- Reduces maintenance costs with easy access for inspection and cleaning.

- Applications

- Particulates, Granular materials, Agricultural products, Seeds

- End products

- Grass seeds, Pelleted seeds, Seed blends, Vegetable seeds, Grain seeds, Seed coatings, Seed fractions, Alfalfa seeds

- Steps before

- Drying, Disinfection, Conditioning, Priming

- Steps after

- Coating, Packing, Sorting

- Input ingredients

- seeds, raw materials for sieving

- Output ingredients

- calibrated seeds, sorted seed fractions, fractionated materials

- Market info

- Sieve size

- 600x800 mm

- Number of sieves

- 3 sieves standard, expandable to 7 or 10 fractions

- System configuration

- Plug, play with inlet system, dust/noise hood, and control box

- Sieve changing method

- No-tool sieve changing system

- Operation type

- Lab scale up to high volume sieving

- Inspection access

- Easy to open for inspection

- Sieve System

- Vibrating

- Sieve Changing

- No-tool, Easy Exchange

- System Configuration

- Plug, Play

- Inspection Accessibility

- Easy to Open

- Noise Reduction

- Dust/Noise Hood Equipped

- Scalability

- Lab to High Volume

- Fraction Sorting

- 4-10 Fractions in One Run

- Abrasion resistance

- Suitable for abrasive seed materials

- Cleanability

- Easy to clean, no loose parts

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Corrosive resistance (e.g. acids)

- Standard industrial applications

- Biological compatibility

- Applicable in seed processing

- Machine footprint

- 600x800 mm sieves

- Sieve size

- 600x800 mm

- Sieve configuration

- Up to 10 fractions

- Discharge method

- 4 fractions standard, expandable to 7 or 10

- Control panel type

- Control box, plug, play

- Noise control

- Dust/noise hood

- Sieve Clamping System

- No-tool changing system

- Sieve Capacity

- 3 sieves of 600x800mm

- Scalability

- Lab scale up to high volume sieving

- Fraction Sorting

- 4 standard, up to 10 with extra sieve boats

- Integration

- Plug, play with control box