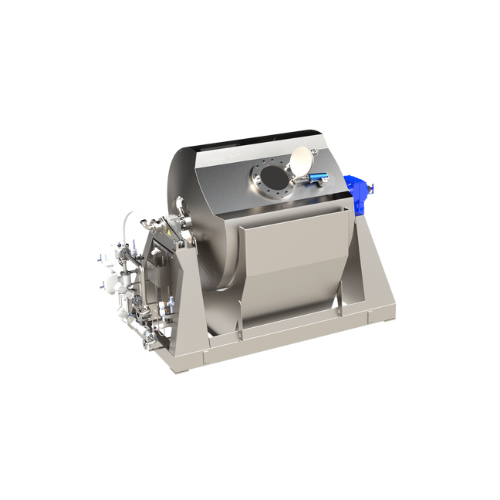

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal processing with a rotary cooker designed for optimal steam heating, enhancing productivity and reducing processing time.

Cooks and Mixes Grains Efficiently

The Rotary Cooker from CEREX AG is engineered to enhance your food processing operations, particularly in the cereal and snack industries. This cooker distinguishes itself with a patented Bichsel system, ensuring uniform steam heating through its unique vessel geometry and steam admission process. The rotary cooker effectively handles continuous cooking, heating, and mixing of grains, making it ideal for producing cornflakes, granola clusters, muesli base flakes, and puffed rice snacks. With a capacity of up to 500 kg/h, it supports high-volume production while maintaining product quality, thanks to its pressure-controlled operation that optimizes cooking phases. Designed with process-optimized vessel geometry and an internal lid structure that prevents dead zones, it ensures consistent results and easy cleaning. Customizable with or without insulation, the cooker also offers low maintenance needs, making it a reliable choice for efficient, high-speed production lines in food processing facilities.

Benefits

- Enhances productivity by processing up to 500 kg/h with fewer units.

- Ensures uniform heating, improving product uniformity and quality.

- Reduces operational costs through low maintenance requirements.

- Optimizes cooking phases with programmable control for precise processing.

- Facilitates easy integration and seamless cleaning into existing production lines.

- Applications

- Murmura, Snacks, Puffed products, Cereals, Nuts, Bars, Coated products, Granola, Instant food, Seeds, Breakfast cereals, Müsli, Flakes, Crispies

- End products

- Muesli base flakes, Rice crispies, Instant oatmeal, Cornflakes, Granola clusters, Roasted seeds, Granola bars, Roasted nuts, Soy protein snacks, Murmura puffed rice, Coated almonds

- Steps before

- Flaking, Puffing, Granola Mixing

- Steps after

- Coating, Drying, Storage, Handling, Packing

- Input ingredients

- Output ingredients

- Market info

- CEREX is known for specializing in the production of engineered-to-order (ETO) equipment, providing customized industrial solutions with a strong emphasis on innovation, quality, and customer satisfaction in niche market segments.

- Volume

- 2700 liters

- Pressure

- up to 4.5 bar

- Throughput

- up to 500 kg/h

- Pressure control

- Pressure-controlled or pressure/temperature-controlled

- Vessel geometry

- Process-optimized

- Lid design

- Optimized internal geometry for preventing dead zones

- Mixing,cooking phases

- Various phases can be programmed

- Cleaning method

- Easy to clean

- Insulation

- With or without insulation

- Maintenance

- Low maintenance

- Working mechanism

- Steam heating

- Integrated steps

- Mixing and cooking phases

- CIP principles

- Easy to clean

- Batch vs. continuous operation

- Batch

- Process optimization

- Pressure/temperature controlled

- Loading efficiency

- Maximized vessel loading

- Dead zone prevention

- Optimized internal geometry

- Automation level

- Programmable phases

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel

- Biological compatibility

- Food-grade materials

- Volume

- 2700 liters

- Pressure

- up to 4.5 bar

- Throughput

- up to 500 kg/h

- Control system

- Pressure-controlled or pressure/temperature-controlled

- Process phases

- Various mixing and cooking phases programmable

- Insulation

- With or without insulation