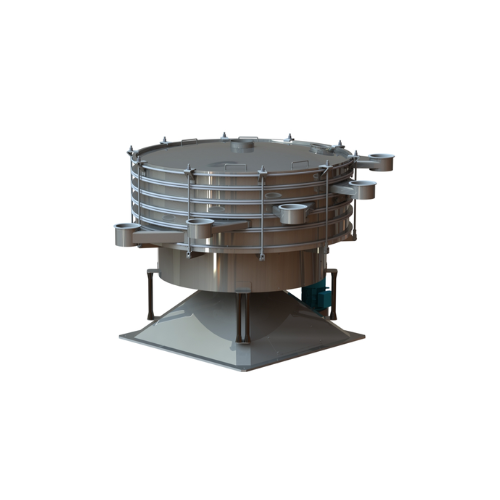

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screeners designed to gently handle and precisely separate your grain-based products, ensuring quality and minimizing material loss in continuous operations.

Screens and Separates Food Granules Effectively

The ScreenersCEREX from CEREX AG is designed to enhance your food processing line with its specialized tumbler screening technology. Employing adjustable three-dimensional agitation, it ensures that particles span across screen decks evenly, reducing abrasion and dust generation while maximizing separation accuracy. Ideal for cereals, granola, nuts, and coated products, it efficiently processes items like cornflakes, puffed rice, and crispy snacks. With options for multiple decks and a semi-automatic operation, this screener integrates seamlessly into continuous production lines. Built with a fully enclosed design to prevent dust emissions and featuring a quick-release locking mechanism for easy deck changes, the ScreenersCEREX minimizes mechanical stress on your facility and offers hassle-free maintenance.

Benefits

- Minimizes product breakage and dust for higher quality outputs.

- Enhances product purity with precise separation and screening.

- Reduces maintenance time through quick-change deck system.

- Decreases operational strain on infrastructure with gentle mechanical design.

- Supports diverse product formats from granola to crispy snacks.

- Applications

- Murmura, Puffed products, Cereals, Nuts, Coated products, Granola, Instant food, Seeds, Breakfast cereals, Müsli, Flakes, Crispies

- End products

- Instant oatmeal, Puffed rice, Coated nuts, Cornflakes, Breakfast granola bars, Seed mixes, Spiced murmura, Granola mix, Muesli flakes, Crispy rice

- Steps before

- Flaking, Puffing, Granola production, Coating

- Steps after

- Packaging, Further treatment, Coating, Storage

- Input ingredients

- raw grain products, high-quality raw materials, finished product

- Output ingredients

- multiple fractions, specific size separation, reduced dust generation, enhanced flavor, gentle processed products

- Market info

- CEREX is known for specializing in the production of engineered-to-order (ETO) equipment, providing customized industrial solutions with a strong emphasis on innovation, quality, and customer satisfaction in niche market segments.

- Screen decks

- Multiple, interchangeable

- Residence time

- Adjustable

- Dust emission

- Fully enclosed design

- Deck change

- Semiautomatic

- Locking mechanism

- Quick-release

- Mechanical stress

- Minimized

- Abrasion

- Minimized

- Working mechanism

- Tumbler screener with adjustable throwing actions

- Integrated steps

- Multiple fractions and specific size separation

- Residence time

- Adjustable

- Cleaning method

- Permanently cleaned by large-size balls

- Dust control

- Fully enclosed design prevents dust emissions

- Screen deck change

- Semiautomatic change with quick-release locking

- Minimized mechanical stress

- Design minimizes building stress

- Product compatibility

- Gentle handling to minimize breakage and abrasion

- Abrasion resistance

- Minimized abrasion due to quick spreading across screen decks

- Density/particle size

- Varies

- Can handle multiple fractions and specific size separation

- Cleanability

- Fully enclosed design prevents dust emissions, includes automatic screen cleaning with large-size balls

- Corrosive resistance (e.g. acids)

- Designed to minimize abrasion and reduce mechanical stress

- Screening method

- Tumbler screener

- Screen decks

- Multiple, quick-release

- Design

- Fully enclosed, dust-proof

- Cleaning mechanism

- Large-size balls

- Agitation mechanism

- 3D particle agitation

- Changeover mechanism

- Semiautomatic

- Locking mechanism

- Quick-release locking

- Output design

- Minimal product residue

- Footprint

- Compact

- Screen decks

- Interchangeable

- Throwing actions

- Adjustable

- Deck changing system

- Semiautomatic

- Locking mechanism

- Quick-release