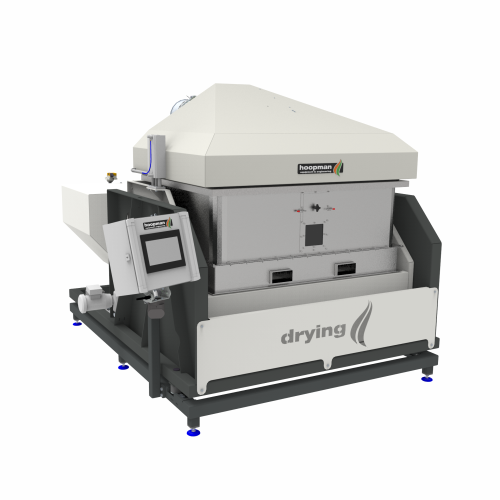

Seed drying system for large volume coated seeds

Achieve precise moisture control in your seed processing operations with a fluid-bed drying system designed for high-capacity batches, ensuring consistent quality and optimal seed treatment results.

Dries and Fluidizes Coated and Treated Seeds

The BD300 Box Drying 300L by Hoopman Equipment & Engineering is designed for high-capacity drying of seeds, especially engineered for maximizing efficiency in seed processing and treatment facilities. Utilizing a fluid-bed drying approach, the BD300 ensures optimal moisture reduction and fluidization for uniform drying of coated, pelleted, and treated seeds. This robust system tackles moisture monitoring with integrated load-cells to provide real-time data throughout the drying process. A key feature is its removable stainless steel drying box, allowing seamless integration with existing hot-water treatment plants and enabling simultaneous loading and drying. The PLC and HMI controls offer precise protocol settings, including multi-step drying with variables like fan speed adjustments to minimize energy consumption. The BD300 excels in flexibility and utility, designed to handle diverse applications in agriculture, horticulture, and seed processing industries, while its stainless-steel construction enhances durability and resistance to corrosion.

Benefits

- Enhances drying efficiency and seed quality with precise moisture monitoring.

- Reduces operational downtime through dual-use removable drying boxes.

- Optimizes energy use with programmable fan speed adjustments.

- Increases integration flexibility with compatibility for existing treatment systems.

- Extends equipment lifespan with durable stainless steel construction.

- Applications

- Pelleted seeds, Agricultural products, Treated seeds, Seeds, Coated seeds

- End products

- Pelleted kale seeds, Coated sunflower seeds, Processed wheat seeds, Hybrid corn seeds, Treated soybean seeds

- Steps before

- Coating, Pelleting, Seed Treatment

- Steps after

- Transport, Rinsing, Treatment, Conditioning, Packing

- Input ingredients

- coated seeds, pelleted seeds, treated seeds, wet seeds

- Output ingredients

- dried seeds, moisture-reduced seeds

- Market info

- Capacity

- 300 L

- Automation

- PLC-controlled

- Material

- Stainless steel

- Fluidization method

- Fluid-bed

- Moisture monitoring

- Load-cells

- Box characteristics

- Removable

- Control interface

- HMI

- Drying process

- Batch

- Versatility

- Transportable box

- Tilting mechanism

- Backwards/forwards

- Working mechanism

- Fluid-Bed drying

- Integrated steps

- Load cells for moisture monitoring

- Cleaning method

- Standard box tippers

- Batch vs. continuous operation

- Batch

- Automation level

- PLC and HMI controlled

- Box removal flexibility

- Transport/rinsing/treatment

- Abrasion resistance

- Yes

- Cleanability

- High (stainless steel)

- Corrosive resistance

- Yes (stainless steel)

- Density/particle size

- Varied (custom loading)

- Container Type

- Stainless Steel Box

- Usage

- Drying/Treatment/Transport

- FDA materials

- Stainless Steel Construction

- Machine footprint

- Not specified

- Drying box capacity

- 300L

- Box material

- Stainless steel

- Box shape

- Rectangular with special corners

- Discharge method

- Box tippers

- Box removability

- Removable and transportable

- Control panel type

- PLC and HMI

- Integration

- Removable drying box with standard box tippers

- Material

- Stainless steel

- Box removal capability

- For transport/rinsing/treatment