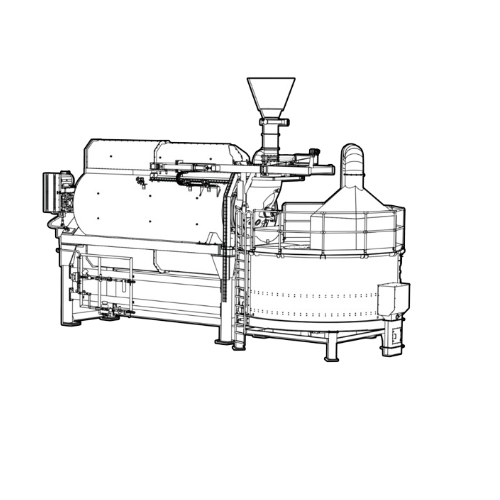

Industrial malt roaster for specialty malts

Optimize malt roasting with precision control over heat distribution, ensuring consistent quality and flavor development across crystal and roast malts, perfect for producers aiming to enhance specialty malt production.

Roasts and Mixes Specialty Malts and Grains

The Industrial Malt Roaster FRD M by Hamburg Dresdner Maschinenfabriken is engineered to transform green or dry malt into high-quality specialty malts. Utilizing an external heating oven with hot air distribution, it ensures even roast and prevents hot-spots, critical for consistent aroma development. Ideal for the food and beverage industry, it accommodates grains such as barley, crystal malt, and roast malt, resulting in products suited for malt production, brewing, and distilling. With batch sizes reaching up to 4,000 kg, it employs a gentle Mixing process, ensuring homogeneity and quality retention in high-moisture conditions. The robust design, featuring a front gate with axial movement and a round cast drum rear, minimizes wear and avoids product deposits. This malt roaster is compatible with additional processes like cooling and integrates seamlessly into existing operations. Optional material configurations and engineering support allow customization for unique production requirements.

Benefits

- Enhances product consistency with uniform roasting, mitigating quality variations.

- Increases operational efficiency by minimizing manual adjustments through axial movement features.

- Reduces energy usage via optimized hot air distribution, promoting sustainable manufacturing.

- Ensures safety in high-moisture environments with a design that prevents hot-spots and product deposits.

- Offers scalability with batch processing capacity up to 4,000 kg, accommodating diverse production needs.

- Applications

- Grains, Malt, Barley, Seeds

- End products

- Malted barley, Specialty malt, Roast malt, Crystal malt

- Steps before

- Cleaning, Pre-Treating, Dehulling

- Steps after

- Cooling, Aroma Development, Grinding

- Input ingredients

- green malt, dry malt, barley

- Output ingredients

- roasted malt, specialty malts

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Batch size

- 1800–3500 kg

- Filling weight

- 3300–5100 kg

- Roast malt bulk density

- 633 kg/m³

- Chrystal malt bulk density

- 600 kg/m³

- Heating system

- External with hot air distribution

- Drum design

- Round cast design without spokes

- Preventive features

- No transmission-slip and wear due to differential speeds

- Product safety

- Bacteria filter of the cooler

- Working mechanism

- External heating oven with hot air distribution

- Integrated steps

- Heating, mixing, and cooling processes

- Batch vs. continuous operation

- Batch

- Energy efficiency

- Energy savings design

- Product safety

- Avoids hot-spots, ensuring homogenous roasting

- Flexibility

- Processes both green and dry malt

- Abrasion resistance

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Depends on model size (e.g., FRD 2000/M, FRD 4000/M)

- Drum size

- Based on batch sizes (e.g., 1800–2000 kg for Chrystal malt)

- Discharge method

- Axial movement on a railway system

- Heating system

- External heating oven with hot air distribution

- Construction

- Round cast design without spokes

- Discharge method

- Front gate with axial movement on a railway system

- Bacteria filter

- Standalone