Automatic sieve for pellet separation

Efficiently separate and clean seeds and pellets, ensuring product integrity from start to finish in your processing line.

Separates and Cleans Seeds and Pellets Efficiently

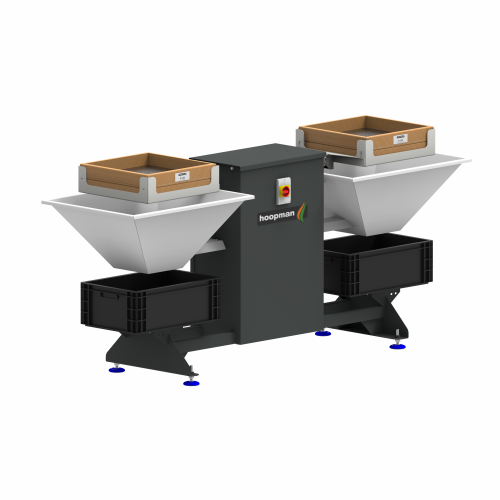

The RS480 Reciprocating Sieve from Hoopman Equipment & Engineering is a versatile solution designed for the efficient separation and cleaning of seeds and pellets. This machine excels in eliminating dust, doubles, and blinds, facilitating nearly 100% seed recovery during pelleting operations. Ideal for agriculture, seed processing, and horticulture industries, the RS480 seamlessly integrates into various processing lines, supporting both batch and manual operations.

Its innovative design features minimal moving parts and a simple construction, reducing noise and enhancing safety. With easy ‘no bolt – no tool’ sieve exchanges and quick sieve cleaning, the RS480 ensures seed lot integrity is maintained. The machine accommodates standard 480mm x 480mm sieves and includes two plastic buckets for convenience. Optional accessories, like a sieve storage cart with swivel wheels, enhance operational flexibility. This reciprocating sieve promises efficient processing for agricultural businesses, offering reliable performance without compromising on quality.

Benefits

- Enhances seed recovery to nearly 100%, minimizing product loss.

- Streamlines operations with quick and tool-free sieve changes.

- Lowers operational noise, improving workplace safety and comfort.

- Facilitates easy bin placement and movement with a pallet car.

- Maintains seed lot purity with efficient and simple cleaning processes.

- Applications

- Pellets, Agricultural products, Seed coatings, Horticultural products, Seeds

- End products

- Pelleted seeds, Horticultural pellets, Seedling starter pellets, Seed packets, Coated seeds, Cleaned agricultural seeds

- Steps before

- Pelleting, Seed Handling, Dust Removal

- Steps after

- Pellet Quality Check, Storage, Final Packaging

- Input ingredients

- pellets, seeds, dust, doubles, blinds

- Output ingredients

- cleaned pellets, good pellets, sieved seeds

- Market info

- Noise Level

- Low noise

- Sieve Size

- 480mm x 480mm

- Sieve Exchange

- Easy 'no bolt – no tool'

- Automation Level

- Automatic hand sieve

- Capacity

- 100–1500 gr. per sieve cycle

- Flexibility

- Moveable with a pallet car

- Cleaning Ease

- Easy and quick sieve cleaning

- Safety

- Improved Safety Design

- Storage

- Sieve storage cart system

- Included Accessories

- 2 plastic buckets

- Working mechanism

- Reciprocating-sieve

- Integrated steps

- Separation of doubles/blinds from good pellets

- Automation level

- Automatic hand sieve

- Cleaning method

- Easy and quick sieve cleaning

- Noise level control

- Low noise due to new technical design

- Setup flexibility

- Moveable with a pallet car

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bin placement ease

- Easy

- Sieve size

- 480mm x 480mm

- Moveability

- Moveable with a pallet car

- Sieve exchange method

- Easy 'no bolt – no tool'

- Storage cart system

- Available, with 4 swivel wheels

- Design

- Simple design with minimal moving parts

- Control panel type

- No bolt – no tool sieve exchange

- Customization for bin handling

- Easy bin placing and removing

- Mobility options

- Moveable with a pallet car

- Sieve storage system

- Sieve storage cart with swivel wheels