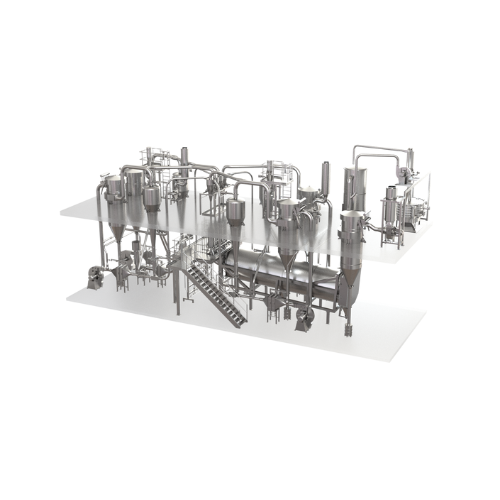

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this advanced puffing system, designed for consistent product quality and high yield in continuous operations.

Expands Grains for Breakfast Cereals and Snacks

The Junior-Puffing system from Cerex AG is designed to transform raw grains into a wide range of breakfast cereals and snack products through an efficient puffing process. This system operates continuously with minimal oversight, maintaining high uptime and low maintenance due to its robust construction and self-cleaning preheaters and reactors. The equipment is crafted from food-grade stainless steel, ensuring hygiene and durability, and it supports seamless integration into existing production lines with its preset operational parameters for consistency. Suitable for processing cereals, granola, seeds, nuts, and coated products, it offers configurations capable of handling from 180 to 240 kg/h, ideal for companies in the food processing and grain industries looking to boost product quality while reducing energy consumption and maintenance costs.

Benefits

- Ensures consistent product quality with automated control of puffing parameters.

- Minimizes operational costs with high uptime and low maintenance requirements.

- Reduces noise pollution with low noise emissions during production.

- Enhances safety and hygiene with a closed circuit system that prevents dust emissions.

- Maximizes resource efficiency with a 95% yield in grain puffing processes.

- Applications

- Murmura, Snacks, Cereals, Bars, Nuts, Coated products, Granola, Instant food, Seeds, Breakfast cereals, Müsli, Flakes, Crispies

- End products

- Muesli base flakes, Energy bars, Puffed rice, Seed mixes, Cornflakes, Granola clusters, Coated cashews, Breakfast cereal flakes, Crispy cereal squares, Snack mixes, Instant porridge, Nut bars, Coated almonds

- Steps before

- Cleaning, Preheating, Loading

- Steps after

- Monitoring, Quality Tracking, Packing, Coating

- Input ingredients

- raw grain products

- Output ingredients

- puffed products, flakes, crispies, murmura, müsli, granola, bars, coated products, nuts, seeds, instant food

- Market info

- CEREX is known for specializing in the production of engineered-to-order (ETO) equipment, providing customized industrial solutions with a strong emphasis on innovation, quality, and customer satisfaction in niche market segments.

- Capacity

- 180-240kg/h - Junior-Puffing

- Capacity

- 350-500kg/h - Single-Puffing

- Capacity

- 700-1000kg/h - Double-Puffing

- Capacity

- 1400-2000kg/h - Quattro-Puffing

- Capacity

- 3000-12000kg/h - Feed-Puffing

- Yield

- Approx. 95%

- Uptime

- Approx. 98%

- Noise emissions

- Low noise emissions

- Dust emissions

- No dust emission

- Automation

- System runs without operator, requiring only monitoring

- Material Construction

- Stainless steel with food-grade finish

- Control

- Pressure and time curves are controlled by means of preset values

- Cleaning

- Self-cleaning preheaters and reactors

- Product Data Logging

- Direct logging of production data to track quality

- System Consistency

- Product formulas and system parameters are saved for consistency

- Cleaning Requirement

- Cleaning required only during product changes or system shutdowns

- Automation level

- System runs without operator, requires only monitoring

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Self-cleaning preheaters and reactors

- Cleaning required only during product changes or shutdowns

- Pressure and time control

- Controlled by preset values

- Noise emissions

- Low noise emissions

- Dust emission

- No dust emission due to closed circuit

- Yield

- Approx. 95%

- Uptime

- Approx. 98% in continuous operation

- Corrosive resistance (e.g. acids)

- High

- Cleanability

- High, Self-Cleaning

- Density/particle size

- 0.5–2.5 g/cm³

- Machine Housing Material

- Stainless steel with food-grade finish

- Configurations

- Junior-Puffing, Single-Puffing, Double-Puffing, Quattro-Puffing, Feed-Puffing

- System Configuration

- Junior-Puffing, Single-Puffing, Double-Puffing, Quattro-Puffing, Feed-Puffing

- Material Finish

- Stainless steel with food-grade finish

- System Parameters

- Preset values for operating accuracy

- Product Formula Saving

- Enabled