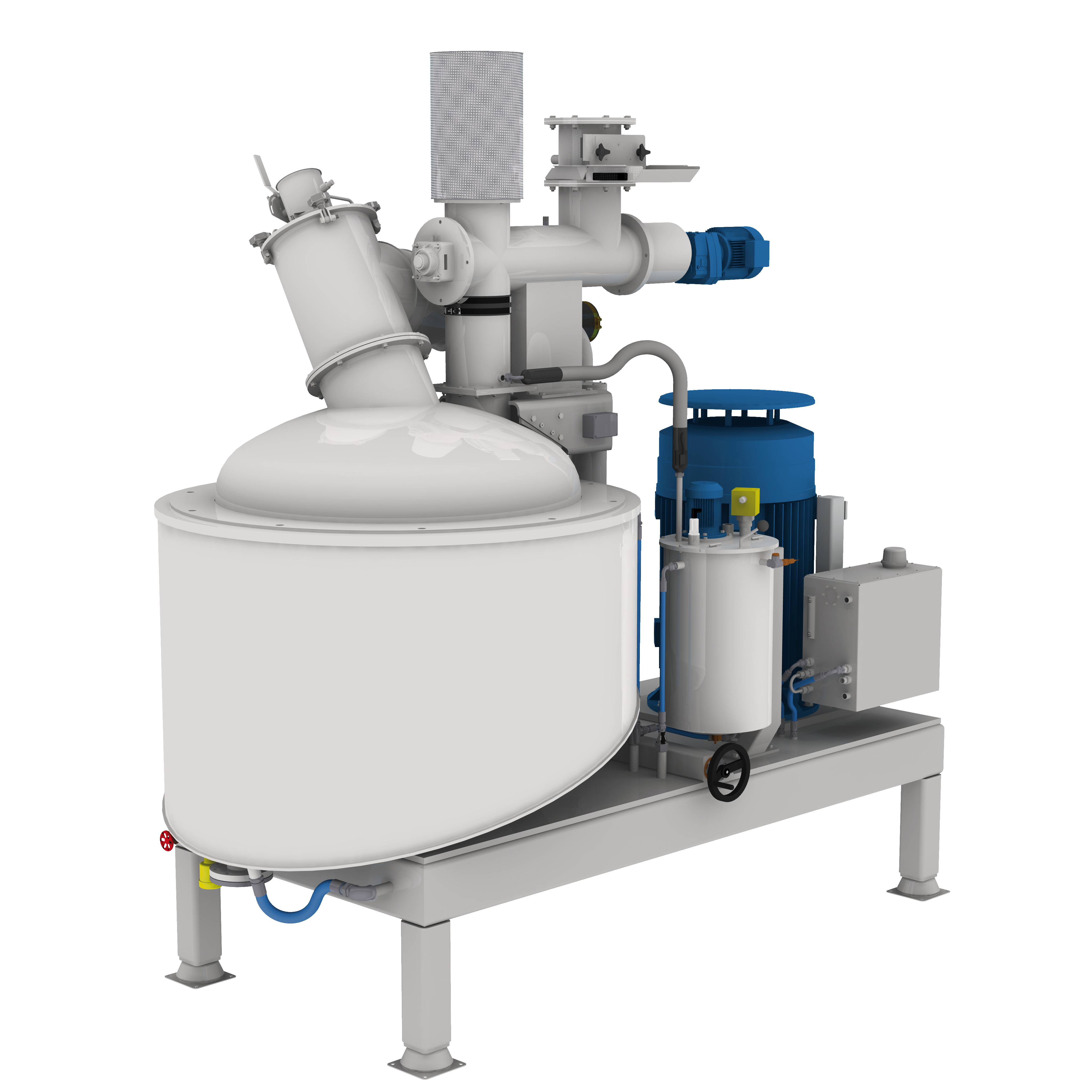

Cocoa liquor grinding line

After roasting and cracking chocolate beans (without husks), the following process is the grinding. Grinding is the process of going from the cocoa nibs into cocoa liquor, obtaining with this pure cocoa mass in liquid form.

Accurate temperature control during the cocoa grinding process

This cocoa grinding machine from Royal Duyvis Wiener keeps the cocoa grinding process as simple as possible whilst paying close attention to every single detail.

The cocoa grinding process begins by feeding cocoa nibs into the chamber via a screw.

Knives then commence their work, and the ground material leaves the machine through a specially designed sieve. The sieve on the cocoa grinding machine can be adjusted. Making it possible, to alter the fineness of the final product during the cocoa grinding process.

The management of temperature is paramount during cocoa grinding process, due to grinding nibs in large volumes requires large amounts of energy, where heat is produced; for this reason the airflow within the cocoa-grinding machine is controlled accurately in order to stabilize the temperature.

Benefits

- High capacities are possible

- An adjustable sieve means the fineness can be altered throughout the cocoa grinding process

- All moving parts of our cocoa grinding technologies are made with high-grade materials

- The cocoa grinding process can be customized with tanks, platforms, and pumps

- Cocoa grinding solutions come fully tested and delivered on skids, so you can begin the cocoa grinding process right away