Cylinder sieving system for seed and pellet calibration

Simplify your seed and pellet calibration with a rotary cylinder system designed for precision sieving and efficient shape calibration, making soft changes without tools for seamless integration into your existing production line.

Sieves and Calibrates Seed and Pellet Sizes

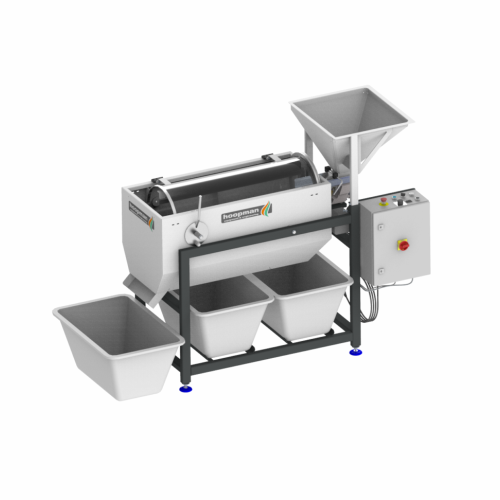

The CSS400 Cylinder Sizing System from Hoopman Equipment & Engineering revolutionizes seed and pellet calibration with its straightforward design and efficient operation. What sets the CSS400 apart is its rotating cylinder mechanism, allowing for accurate sieving and calibration without the need for tools. This flexibility makes it an essential asset for seed processing companies and pelleting industries.

The system operates by rotating a cylinder to effectively separate and calibrate pellets based on size and shape, ideal for products like seed pellets, alfalfa, and grain pellets. It features a user-friendly control panel that allows you to adjust the dosing and rotating speeds, providing you with control over your batch and continuous operations. With a frequency-controlled dosing system, the CSS400 ensures consistent and variable product dosing.

Engineered for easy maintenance, the design includes minimal moving parts, and its cylinder exchange process requires no tools or bolts, reducing downtime significantly. The system is built to integrate seamlessly into your existing production line, enhancing efficiency and precision while maintaining low energy consumption. The CSS400 is versatile enough to meet the demands of various agricultural and seed processing applications.

Benefits

- Enhances product quality by accurately calibrating seed and pellet sizes.

- Minimizes operational downtime with quick, tool-free cylinder changes.

- Lowers energy costs through efficient, frequency-controlled dosing.

- Increases operational flexibility with adjustable control for both batch and continuous processes.

- Simplifies maintenance with a design featuring minimal moving parts.

- Applications

- Seed processing, Seed calibration, Pellets calibration, Agricultural products, Pelleting processes

- End products

- Vegetable seed calibrations, Seed pellets, Grain pellets, Alfalfa pellets, Grass seed pellets

- Steps before

- Pelleting, Drying, Conditioning

- Steps after

- Coating, Sorting, Packing

- Input ingredients

- seed, pellets

- Output ingredients

- calibrated seed, calibrated pellets

- Market info

- Sieve Changing

- No-tool

- Design

- Simple

- Dosing Control

- Electronically variable

- Control Panel

- Easy for dosing speed and rotating speed

- Dosing Speed

- Frequency controlled system

- Parts

- Minimal moving parts

- Working mechanism

- Rotating cylinder

- Sieve changeover

- No-tool exchange

- Control method

- Easy control panel

- Variable dosing

- Electronically variable

- Cylinder exchange method

- No bolt

- Dosing control

- Frequency controlled

- Operation type

- Batch

- Cleanability

- Easy ‘no bolt – no tool’ cylinder exchange ensures cleanability

- Sieve change method

- No-tool exchange

- Control panel type

- Easy control panel

- Design simplicity

- Simple design

- Product dosing system

- Electronically variable

- Frequency controlled system

- Dosing system

- Control panel type

- Simple control panel

- Cylinder exchange

- No bolt – no tool

- Integration possibilities

- Frequency controlled dosing system