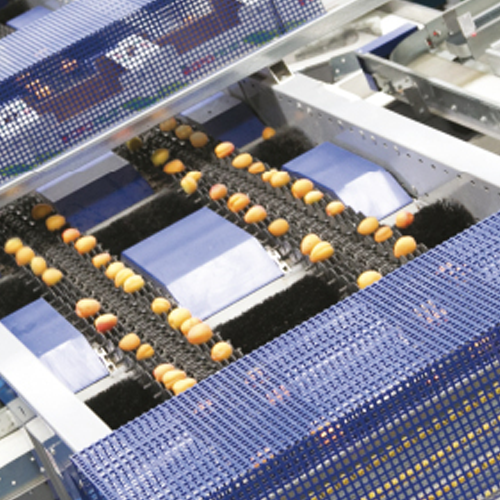

Grading and sorting solutions for apricots

Optimize your fruit production with precise grading and sorting technologies designed to handle a wide variety of fruits, ensuring consistent quality and reducing waste.

Sorts and Grades Fruits Consistently

The Apricot Vision 3 from UNITEC excels at refining fruit quality by providing a robust sorting and grading solution tailored for fruit packing houses and processors. This system applies advanced vision technology to evaluate internal and external fruit characteristics, ensuring precise quality selection across a wide range of products, including apricots, sour cherries, and avocados. With the capacity to manage various fruits like kiwifruit and nectarines, this apparatus supports high-speed, continuous operations on solid fruits.

Integrated automated systems streamline workflow, reducing manual intervention to zero, and enhancing operational efficiency. The Apricot Vision 3 seamlessly integrates into existing processing and packaging lines, accommodating both low and high production needs while maintaining consistent quality for evolving market demands.

Energy-efficient design is achieved through optimized control systems, contributing to reduced operational costs. Constructed from durable materials, it stands up to demanding environments and offers compatibility with in-place cleaning systems to minimize downtime. Comprehensive customization options, backed by UNITEC’s engineering support, allow tailoring of the equipment to match specific throughput and process requirements, fostering optimal performance and customer satisfaction.

Benefits

- Ensures consistent fruit quality, enhancing customer satisfaction and market continuity.

- Eliminates manual sorting, significantly reducing labor costs and errors.

- Optimizes energy use, lowering operational expenses.

- Maintains high speed with minimal downtime, maximizing throughput.

- Accommodates diverse fruit processing, expanding production versatility.

- Applications

- Cucumbers, Blueberries, Plums, Melons, Tomatoes, Cherries, Pomegranates, Cherry tomatoes, Courgettes, Sour cherries, Apricots, Rounded pears, Elongated pears, Oranges, Hazelnuts, Persimmons, Lemons, Limes, Peppers, Rubin tomatoes, Mandarins and clementines, Avocado, Baby watermelons, Beef tomatoes, Nectarines, Apples, Eggplants, Watermelons, Grapefruits, Peaches, Walnuts, Chestnuts, Kiwifruit

- End products

- Nectarine salsa, Persimmon pudding, Grapefruit segments, Tomato paste, Mandarin segments, Watermelon slices, Kiwifruit salad, Cherry compote, Melon balls, Tomato sauce, Hazelnut spread, Lime juice, Apricot jam, Walnut butter, Watermelon juice, Pickled cucumbers, Guacamole, Apple sauce, Zucchini bread, Cherry tomato garnish, Dried apricots, Maraschino cherries, Lemonade, Cherry pie filling, Bell pepper slices, Plum jam, Baba ghanoush, Roasted chestnuts, Pomegranate seeds, Apricot puree, Candied orange peel, Peach cobbler, Poached pears, Avocado oil, Blueberry muffins

- Steps before

- Harvesting, Cleaning, Prewashing, Inspection

- Steps after

- Quality Control, Packing, Labeling, Distribution

- Input ingredients

- apricots, plums, peaches, nectarines, kiwifruits, mandarins

- Output ingredients

- sorted apricots, packed apricots, quality-selected apricots, calibrated fruits

- Market info

- Accuracy

- Detection of internal and external quality

- Automation

- Manual reduction to zero

- Precision

- High precision in detecting package weight

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Minimal

- CIP/SIP

- CIP 121°C

- Cleaning method

- Automated / Manual

- Energy efficiency

- Low consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Fruit Type

- Apricots, Plums, Peaches, Nectarines, Kiwifruits, Mandarins

- Handling Method

- Sorting, Grading, Packing

- Automation Level

- Full automation

- Discharge Method

- Automatic

- Control Panel Type

- Touch screen interface

- Multi-fruit Capability

- Apricots and similar fruits

- Control panel type

- Touchscreen

- Integration possibilities

- External system integration

- Automation level

- Fully automated

- Adjustable sorting parameters

- Variety-specific customization

- Software interface

- User-friendly interface