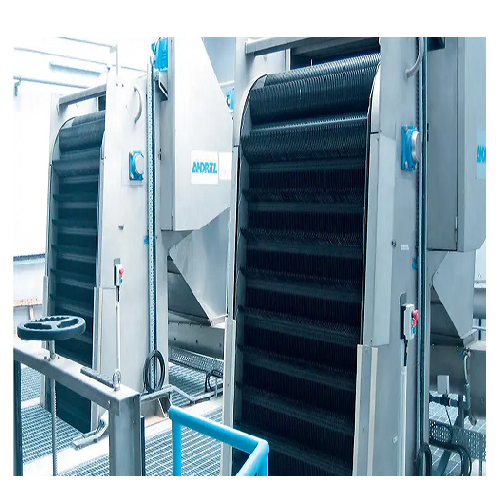

Fine screen for municipal and industrial wastewater treatment

Streamline wastewater treatment with a reliable, self-cleaning fine screen that enhances screening capacity and reduces energy consumption, ensuring optimal separation of fine particles and sludge with minimal maintenance.

Continuously Screens and Cleans Industrial Effluents

The ANDRITZ Aqua-Guard fine screen is an engineered solution designed for efficient, continuous screening in industrial and municipal applications. With its self-cleaning, continuous belt screen system, it excels at processing municipal wastewater, pulp fibers, dye effluents, and more by employing a unique moving/lifting staircase mechanism and exchangeable ABS teeth. This system allows for precise separation and integrates seamlessly into existing infrastructure without requiring channel modifications. The Aqua-Guard offers impressive throughput capabilities, handling flow rates between 150 to 800 m³/hr, with a bi-dimensional mesh system adaptable for diverse operational needs. Its design minimizes energy use and enhances cleaning effectiveness, utilizing a triple cleaning system and specially shaped teeth for high lifting capacities and efficiency. Available in durable material configurations for long-lasting service, it supports extended lifespans of up to 20 years and requires minimal maintenance due to the absence of immersed rotary parts. Configurable for specific customer requirements, it serves a broad range of industries, from textile and tanneries to wineries and breweries, ensuring reliable performance in demanding separation tasks.

Benefits

- Enhances separation precision with unique moving/lifting staircase mechanism.

- Minimizes operational costs through reduced water and energy usage.

- Integrates easily with existing systems without channel modification.

- Extends equipment lifespan with low-maintenance, non-immersed rotary parts.

- Accommodates diverse applications with high capacity and bi-dimensional mesh versatility.

- Applications

- Wineries, Vegetable and fruit processing, Water treatment, Municipal wastewater, Industrial effluents, Pulp and paper, Food processing, Slaughterhouses, Textile industry, Tanneries, Breweries

- End products

- Industrial wastewater, Grape pomace, Vegetable peels, Pulp fibers, Treated water, Leather scraps, Sewage sludge, Animal by-products, Brewery spent grains, Dye effluent, Fruit pulp

- Steps before

- Intake channel setup, Water flow management, Initial water collection, Industrial effluent discharge

- Steps after

- Sludge treatment, Biofiltration, Secondary water treatment, Waste material extraction

- Input ingredients

- municipal sewage, intake water, industrial wastewater, pulp and paper waste, textile wastewater, tannery effluents, food processing waste, meat processing waste, slaughterhouse waste, vegetable processing waste, fruit processing waste, wineries wastewater, breweries wastewater

- Output ingredients

- screened water, reduced contaminants, separated fine particles, cleaned effluent, extracted screening material, reduced sludge

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Flow Rate

- 150 - 800 m³/hr

- Mesh Size

- 2501

- Width

- 300 - 1, 000 mm

- Height

- 1 - 2 m

- Automation

- Self-washing

- Working mechanism

- Self-washing continuous belt screen

- Automation level

- Low supervision

- Energy efficiency

- Reduced energy consumption

- Cleaning method

- Self-cleaning with retractable teeth

- Cleaning system

- Triple cleaning system

- Capacity adaptation

- Sequential functioning

- Changeover capability

- High - Replaceable ABS teeth

- Application flexibility

- Various applications - Municipal, Industrial, Food

- Density/particle size

- 50–1000 µm

- Screening system type

- Continuous belt screen

- Application Type

- Municipal, Industrial, Food processing

- ISO Certification

- ISO 9001

- Width

- 300 - 1, 000 mm

- Height

- 1 - 2 m

- Flow rate

- 150 - 800 m³/hr

- Mesh dimension

- Bi-dimensional

- Control panel type

- Self-cleaning continuous belt

- Discharge method

- Sequential functioning

- Screen width

- 300 - 1, 000 mm

- Screen height

- 1 - 2 m

- Flow capacity

- 150 - 800 m³/hr