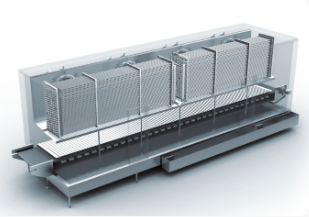

IQF (Individual Quick Freezing) freezer

Food products such as berries and fries in large volumes may tend to stick and form clusters when they go to the freezer. These products must be frozen individually with uniform quality before preparing them for packing.

Freezing food products individually on perforated trays with pulsating air streams

The IQF freezer from Orange Freezing is a fluidized bed freezing system for food products. The system is equipped with food-grade perforated plastic tray bottoms with centrifugal fans and an agitation system that pulsates air. The process starts with the products being conveyed on a vibrating belt that makes them move and bounce around. While the products are moving, they are quickly frozen to avoid sticking to one another and to prevent dehydration. Then they are gently and uniformly frozen down to their cores as they move down the line and exit through a conveyor. The unit has a capacity range of 2 to 10 tons per hour.

Benefits

- High output, between 2 and 10 tons per hour

- Minimal dehydration of products

- High yield (no damage or clustering of products)

- Uniform freezing of each piece of product