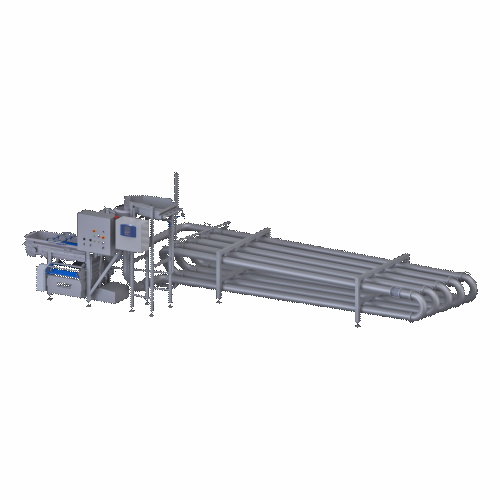

Germ reduction system for leafy greens and produce

Optimize your processing line with a flexible germ reduction solution that ensures every product, from cut salad mixes to ready-to-eat apple slices, is thoroughly disinfected and flushed, enhancing both safety and shelf life.

Reduces Germs and Disinfects Produce

The Vortex system for germ reduction by KRONEN GmbH revolutionizes hygiene in food processing with its innovative pipe-based submergence flume technology. Designed to tackle bacterial contamination in salads, fruits, and vegetables, it employs a controlled retention time that ensures effective disinfection using washing additives. This system seamlessly integrates with existing production lines, enhancing its adaptability and efficiency. With a capacity of up to 3,500 kg/h, it offers high throughput without compromising product integrity. Suitable for applications in the food and beverage industries, it processes diverse products like cut salad mixes, pre-packaged lettuce, and ready-to-eat apple slices. The system’s modular pipe design facilitates easy cleaning, while its flexibility in pipe length and diameter allows tailoring to specific customer needs. The Vortex is trusted for continuous operations and is compatible with upstream GEWA washing machines, ensuring comprehensive purification of produce.

Benefits

- Optimizes germ reduction by ensuring complete product immersion during disinfection.

- Increases production efficiency with a capacity of up to 3,500 kg/h.

- Enhances product hygiene for extended shelf life and reduced spoilage.

- Customizable integration meets diverse production line configurations.

- Simplifies maintenance with a modular design for easy cleaning access.

- Applications

- Whole carrots, Lettuce, Apples, Salads, Fruits, Vegetables, Root vegetables, Grapes

- End products

- Pre-packaged lettuce, Cut salad mixes, Pre-washed root vegetable medley, Table grapes, Peeled and sliced whole carrots, Bagged salad blends, Ready-to-eat apple slices, Washed salad leaves

- Steps before

- Pre-washing, Sorting, Trimming

- Steps after

- Drying, Mixing, Packaging

- Input ingredients

- whole carrots, cut salad mixes, root vegetables, lettuce, vegetables, fruits, apples, grapes, pre-washed products

- Output ingredients

- disinfected whole carrots, disinfected cut salad mixes, germ-reduced vegetables, processed lettuce, germ-reduced fruits, prolonged shelf life products

- Market info

- KRONEN is known for manufacturing industrial food processing equipment, specializing in washing, cutting, peeling, and packaging machinery, recognized for innovation, high quality, and efficiency in automated food processing solutions.

- Capacity

- up to 3, 500 kg/h (with a retention time of 120 seconds)

- Power

- 5.9 kW

- Voltage

- 3~400 V N/PE

- Frequency

- 50 Hz

- Fresh water connection

- 3/4 inch (GEKA coupling)

- Infeed/placement height

- 2170 mm

- Outfeed/delivery height

- 819 mm

- Working mechanism

- Submergence flume with laminar flow

- Integration level

- Inline integration with GEWA washing machine

- Batch vs. continuous operation

- Inline continuous

- Cleaning method

- Modular pipe system

- Retention time

- 120 seconds

- Flexible adjustment

- Customizable pipe length

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies with configuration

- Pipe diameter

- 200 mm

- Retention time

- 120 seconds

- Product capacity

- up to 3, 500 kg/h

- Pipe system

- Modular, customizable length

- Outfeed method

- Belt or vibration

- Infeed height

- 2170 mm

- Outfeed height

- 819 mm

- Water flow type

- Laminar flow

- Pipe Length

- Customizable to customer requirements

- Integration Possibility

- Flexible for integration into existing production facilities

- Outfeed Module

- Belt or vibration outfeed options

- Control Adjustment

- Adjustable pumps for laminar water flow

- System Integration

- Can be integrated with GEWA washing machine

- Visual Monitoring

- Sight glasses for product flow monitoring

- Dosing Module

- Integrated dosing system for washing additives