Automated precision spraying dispenser for high viscosity materials

Achieve precise spraying and consistent coating results across diverse materials with a highly reliable dispenser that integrates seamlessly into your production line, ensuring minimal overspray and maintaining high edge definition for critical applications.

Dispenses and Sprays Liquids with Precision

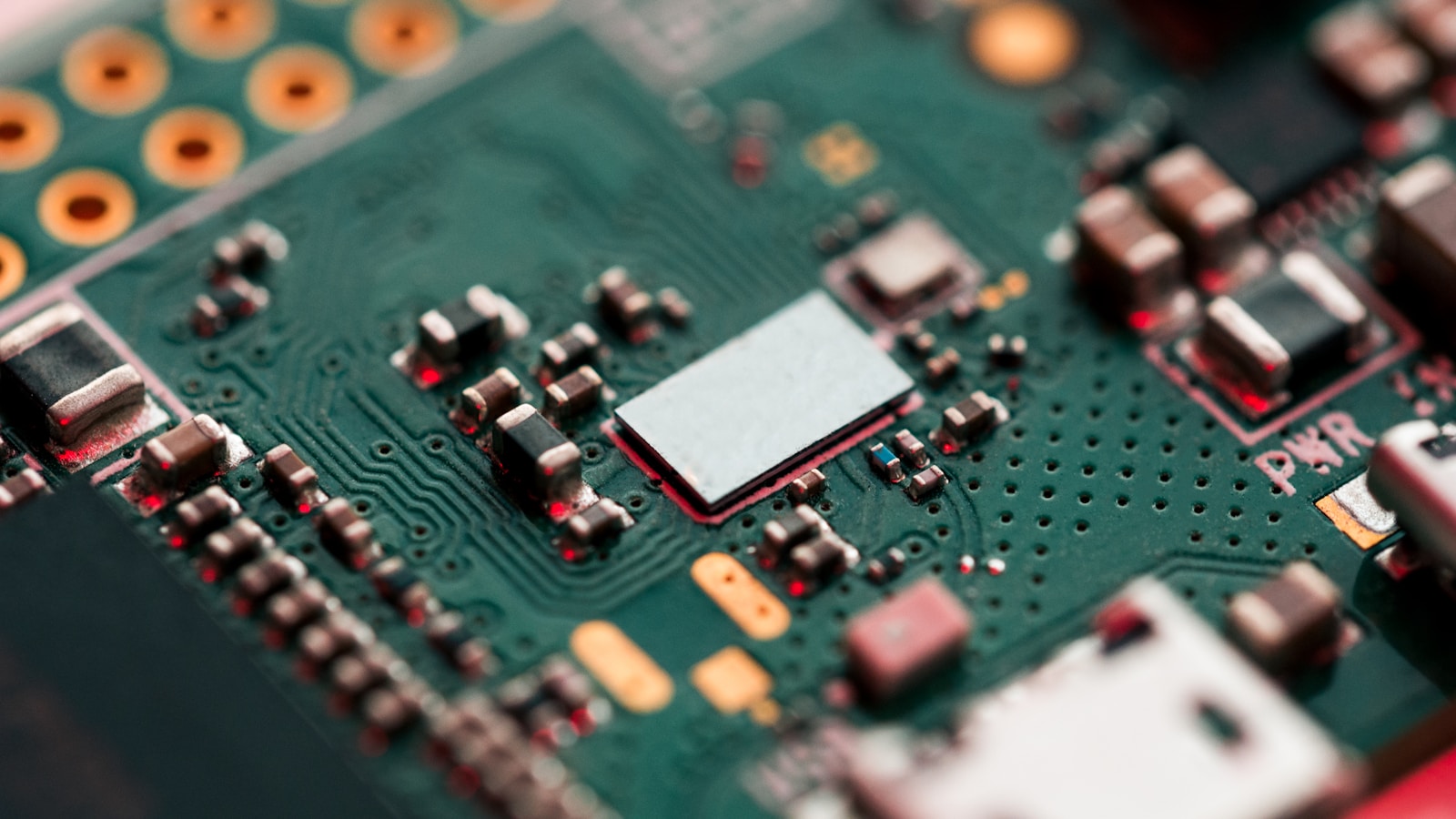

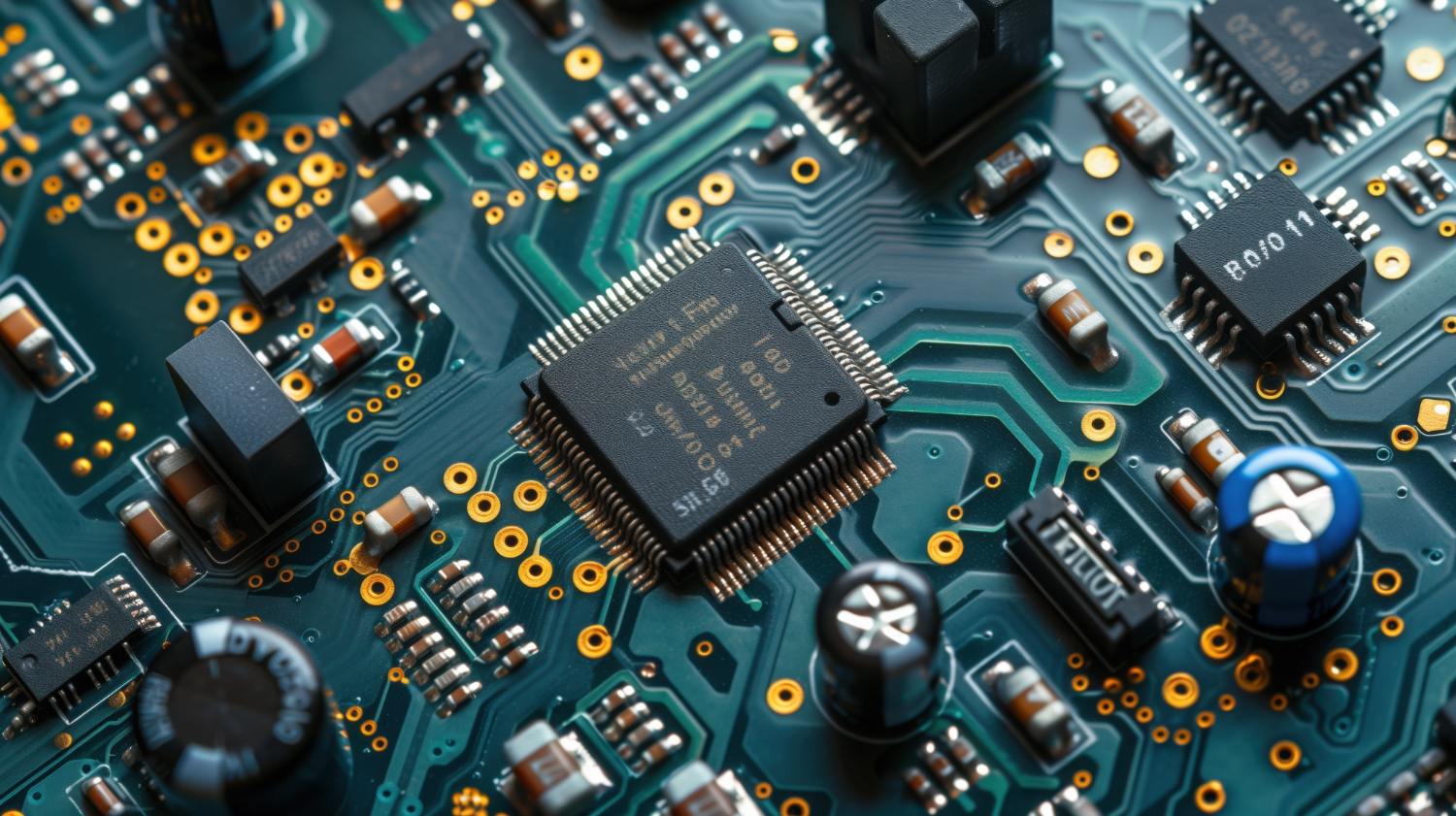

The eco-SPRAY from ViscoTec’s preeflow brand is an automated spraying system designed for precision in the medical and electronics manufacturing industries. It leverages an endless piston principle, ensuring volumetric precision across a range of viscosities. This system is ideal for applications like optical bonding, conformal coating, and thermal management, catering to end-products such as implantable medical devices and circuit boards.

Featuring an advanced low-flow spray chamber, the eco-SPRAY minimizes overspray while maintaining high edge definition. It supports both continuous and intermittent operations, making it versatile for various production lines. With a dosing flow adjustable from 0.5 to 6.0 ml/min and viscous materials capability, it integrates seamlessly into automated processing environments.

Engineered for reliability, this equipment is constructed with robust materials, ensuring durability and performance consistency. The compact design, coupled with low energy consumption, makes it a cost-effective choice. Additionally, the eco-SPRAY offers full customization and engineering support, allowing you to optimize it for specific production needs.

Benefits

- Ensures precise material application, reducing waste and improving product quality.

- Adapts to various viscosities, providing flexibility across multiple applications.

- Integrates seamlessly into automated lines, enhancing production efficiency.

- Compact design optimizes workspace, fitting easily into existing setups.

- Minimizes maintenance downtime with its robust construction and reliable operation.

- Applications

- Fill, Underfill, Dam, Thermal management, Optical bonding, Bonding, Encapsulating, Conformal coating, Microdispensing, Medical technology, Components, Glob top, Electronic devices

- End products

- Implantable medical devices, Led encapsulation, Circuit boards, Sensor encapsulation, Electronic adhesive films, Microchips, Smartphone assembly, Printed circuit board (pcb) coatings, Chip underfill, Semiconductor packaging, Thermal interface materials, Lcd screens

- Steps before

- Material Preparation, Viscosity Adjustment, Mixing

- Steps after

- Inspection, Quality Control, Final Assembly

- Input ingredients

- low viscosity materials, high viscosity materials

- Output ingredients

- precision spray, nebulized spray, high edge definition spray, consistent spray-image

- Market info

- Visco Tec is known for its precision dispensing and dosing technology, specializing in equipment for viscoelastic fluids, offering reliable, high-quality solutions for industries like pharmaceuticals, food, cosmetics, and general manufacturing, renowned for engineering excellence and innovation.

- Spray Quantity

- 0.05 ml

- Dosing Flow

- 0.5 to 6.0 ml/min

- Dimensions

- Length

- Weight

- 650g

- Viscosity Range

- Low to high viscosity

- Edge Definition

- High

- Spray Control

- Controllable round spray

- Spray Type

- Continuous or Intermittent

- Working mechanism

- Endless piston principle

- Spray type

- Controllable round spray

- Automation level

- Automated

- Sensitivity to viscosity

- Viscosity independent

- Operation mode

- Continuous or intermittent

- Flow controllability

- Adjustable dosing flow (0.5 to 6.0 ml/min)

- Minimum spray quantity

- 0.05 ml

- Edge definition

- High edge definition

- Spraying accuracy

- Constant amount/area

- Viscosity range

- Low to High

- Density/particle size

- Viscosity-independent

- Dimension Length

- 228 mm

- Dimension Diameter

- 35 mm

- Weight

- 650 g

- Control panel type

- Processor-controlled

- Spray pattern adjustability

- Controllable round spray

- Dosing flow adjustability

- 0.5 to 6.0 ml/min

- Spray quantity adjustability

- Minimum 0.05 ml