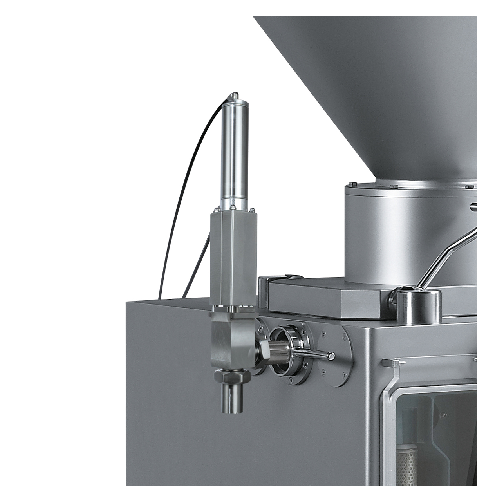

Vertical dosing valve for accurate food portioning

Ensure precision in portioning liquid and semi-liquid food products with a versatile solution that integrates seamlessly into your existing production line, optimizing efficiency and reducing waste.

Portions and Deposits Liquid Food Products

The AR series vertical depositing valve from Risco complements their vacuum filler line by providing a solution for precise, efficient portioning of liquid products like salad dressings, batters, and emulsions. Designed with interchangeable valve stems for various product viscosities, it allows custom exit openings up to 45 mm. Ideal for continuous food processing, the pneumatically actuated valve integrates seamlessly with existing automated depositing systems. Constructed from steel and food-grade plastic materials, it supports high-speed operations, ensuring consistent product quality across bakery, dairy, meat, and pet food industries. Additionally, its compatibility with Risco vacuum fillers enhances operational efficiency, making it a valuable asset for manufacturers focused on accurate and controlled portioning in their production lines.

Benefits

- Ensures dosing precision for liquid and viscous products, enhancing product consistency.

- Seamlessly integrates with existing automatic systems, optimizing workflow efficiency.

- Customizable valve openings accommodate diverse product viscosities, enhancing flexibility.

- Constructed with food-grade materials, it maintains hygiene and compliance standards.

- Pneumatic actuation supports high-speed operations, boosting production capacity.

- Applications

- Ham products, Pet food, Bakery, Mortadella, Fruit and vegetables, Sausage products, Emulsions, Ground meat, Salad dressing, Dairy products, Fish, Cake batters

- End products

- Salmon fillets, Cheese spreads, Chicken mortadella, Dog food pellets, Frankfurters, Diced fruit cocktail, Ground beef patties, Mayonnaise, Chocolate cake batter, Croissants, Canned green beans, Ranch dressing, Sliced ham

- Steps before

- Emulsification, Mixing, Grinding

- Steps after

- Portioning, Packing, Depositing

- Input ingredients

- salad dressing, cake batters, emulsions

- Output ingredients

- boxes, trays, roll stock machines

- Market info

- Risco is known for manufacturing industrial equipment, particularly for meat processing and food production. They specialize in innovative vacuum fillers, portioning systems, and stuffing machines, recognized for quality, reliability, and advanced technology in the food processing industry.

- Portioning precision

- High precision

- Automation

- Pneumatic control

- Exit opening size

- Up to 45 mm

- Integration

- Easy integration in automatic deposit systems

- Material

- Steel and plastic materials suitable for food

- Customizability

- Interchangeable valve stems and housings

- Working mechanism

- Pneumatically actuated valve

- Integration capability

- Easy integration with Risco vacuum fillers

- Customization options

- Interchangeable valve stems and housings

- Portioning precision

- High precision dosing

- Operation type

- Manual / Automatic

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Suitable applications

- Dressing, batters, emulsions

- Machine footprint

- Compact

- Discharge method

- Portioning into boxes, trays, roll stock machines

- Exit opening size

- Up to 45 mm

- Material

- Steel and plastic suitable for food

- Valve type

- Vertical dosing valve

- Integration capability

- Easy integration with automatic deposit systems

- Control panel type

- Electrical connection with Risco fillers

- Integration possibilities

- Easy to integrate in automatic deposit systems

- Valve customization

- Interchangeable valve stems and valve housings