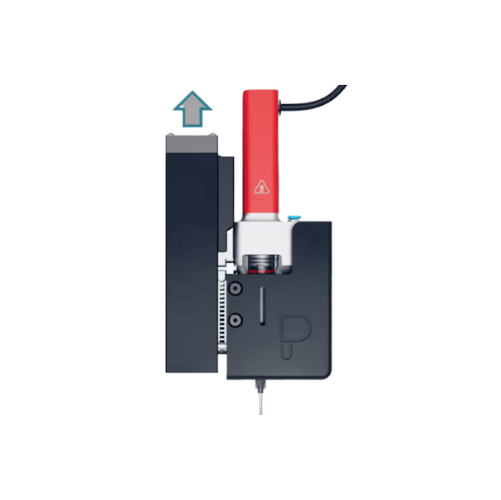

Temperature control system for bioprinting with gelatin

Ensure precise bioprinting outcomes by maintaining accurate temperature control of your materials, vital for optimizing the extrusion process and enhancing the quality of cellular structures and hydrogels.

Manages Temperature for Accurate Bioprinting Extrusion

The temperature control b5 from ViscoTec’s Puredyne® series is a versatile unit designed for precise thermal management in bioprinting. Utilizing a Peltier element for efficient heating and cooling, it can maintain temperatures between 4°C and 40°C, crucial for processing sensitive materials like gelatin and pluronic. This unit ensures consistent material properties, vital for producing high-quality bio-printed tissue scaffolds and cellular structures. It integrates seamlessly with existing bioprinting setups, either directly with the printer or via an optional control unit, allowing for manual and continuous operations. Featuring a PID controller for accurate temperature regulation, the system includes an aluminum sleeve to ensure efficient heat transfer. Its compact design is suitable for both R&D and production environments in biotechnology and tissue engineering sectors. The Puredyne® temperature control b5 supports customizable configurations to meet diverse research requirements, making it an essential tool for advanced bioprinting applications.

Benefits

- Enhances material stability, ensuring high-quality bio-printed structures.

- Achieves precise temperature control, vital for cell survival and consistency.

- Seamlessly integrates into current bioprinting setups, reducing setup time.

- Offers flexible operation with both manual and continuous modes.

- Supports a wide temperature range, expanding material processing capabilities.

- Applications

- Biological materials, Gelatin, Bioprinting, Cell-loaded materials, Pluronic

- End products

- Gelatin-based hydrogels, Bioinks for tissue engineering, Customized cellular structures, Pluronic-based support structures, 3d bio-printed tissue scaffolds

- Steps before

- Material Preparation, Mixing, Material Loading

- Steps after

- Cooling, Inspection, Packing

- Input ingredients

- cell-loaded materials, pluronic, gelatin, biological materials

- Output ingredients

- precisely dosed biological materials, flowable bioprinting materials, layer-formed bioprinting structures

- Market info

- Visco Tec is known for its precision dispensing and dosing technology, specializing in equipment for viscoelastic fluids, offering reliable, high-quality solutions for industries like pharmaceuticals, food, cosmetics, and general manufacturing, renowned for engineering excellence and innovation.

- Temperature Range

- 4–40°C

- Temperature Control

- PID Controller

- Heating and Cooling

- Peltier Element

- Integration

- Bioprinter/Control Unit

- Temperature range

- 4–40°C

- Cooling and heating capability

- Peltier element

- Actuation method

- Bioprinter or optional control unit

- Temperature control

- PID controller

- Integration type

- Quick integration

- Automation level

- Manual / PLC

- Temperature adjustment mechanism

- Reverse polarity

- Biological compatibility

- Yes

- Cleanability

- High

- Temperature sensitivity

- 4–40°C

- Viscosity range

- Low to high viscosity

- Temperature Transmission Material

- Aluminum Sleeve

- Cooling,Heating Functionality

- Yes, via Peltier Element

- Control panel type

- Optional external control unit

- Integration possibilities

- Direct bioprinter integration

- Temperature control range

- 4–40°C