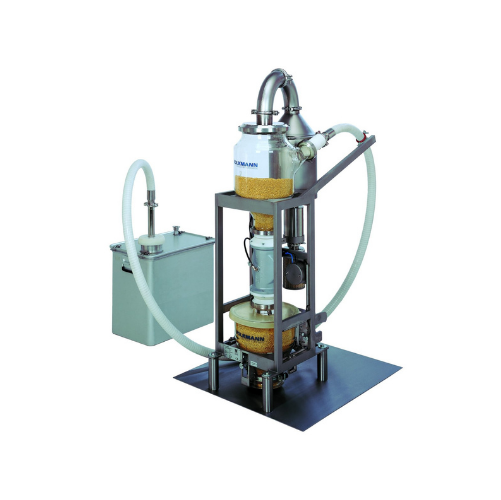

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying designed to prevent mechanical damage, dust generation, and ensure precise dosing throughout your production line.

Gently Transfers Tablets and Powders

The Vacuum Conveyor for Tablets from Volkmann provides a gentle and efficient solution for transferring pharmaceutical tablets, powders, and sensitive materials. Designed to prevent mechanical damage and dust generation, this conveyor ensures the integrity of products such as aspirin, multivitamin, and antibiotic tablets. Utilizing FDA-approved shock-absorbing materials on all product contact surfaces, it minimizes wear and tear while allowing easy and flexible installation. Capable of handling a range of materials from gelatin capsules to chemical granules, it serves both the pharmaceutical and chemical industries. Volkmann’s system supports continuous and automatic operations, seamlessly integrating into processing and packaging lines with customizable options available to meet specific production needs. The conveyor also aligns with GMP and FDA standards, offering safe and compliant operation.

Benefits

- Minimizes product damage and contamination with gentle vacuum transfer.

- Reduces operational costs by eliminating the need for manual handling.

- Ensures compliance with industry standards through FDA-approved materials.

- Enhances production efficiency with flexible, space-saving installation.

- Supports diverse material handling, providing versatility in pharmaceutical and chemical applications.

- Applications

- Pharmaceutical raw materials, Pharmaceutical tablets, Chemical industry products, Sensitive products, Apis

- End products

- Coated tablets, Ibuprofen tablets, Chemical granules, Active pharmaceutical ingredients, Gelatin capsules, Multivitamin tablets, Effervescent tablets, Aspirin tablets, Paracetamol tablets, Antibiotic powders

- Steps before

- Tablet Pressing, Granulation, Tablet Production, Pharmaceutical Raw Material Preparation

- Steps after

- Packing, Coating, Quality Inspection, Pharmaceutical Distribution

- Input ingredients

- tablets, capsules, pharmaceutical raw materials, APIs

- Output ingredients

- tablets, capsules

- Market info

- Volkmann is known for manufacturing vacuum conveying systems, specializing in pneumatic conveying of bulk materials. Their reputation for innovative and reliable equipment solutions in various industries positions them as a trusted provider for engineered-to-order material handling systems.

- Automation

- Reliable and safe automatic product transfer

- Material Handling Type

- Gentle transfer for delicate tablets

- Installation Flexibility

- Easy and flexible to install

- Wear Resistance

- Wear-free product contact surfaces

- FDA Compliance

- FDA approved shock absorbing materials

- Capacity

- Customized to user needs

- Dosing Capability

- Conveys and doses pharmaceutical raw materials and APIs

- Working mechanism

- Vacuum transfer

- Integrated steps

- Gentle transfer process

- Batch vs. continuous operation

- Batch

- Cleaning method

- Wear-free surfaces

- Automation level

- Automatic product transfer

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Tablet press discharge

- Design material

- Glass or FDA approved coatings

- Integration flexibility

- Limited headroom capability

- Control panel type

- PLC / HMI

- Integration possibilities

- Inline with tablet press / Container filling

- Coating material

- Glass / FDA approved shock absorbing materials

- Installation flexibility

- Limited headroom compatible