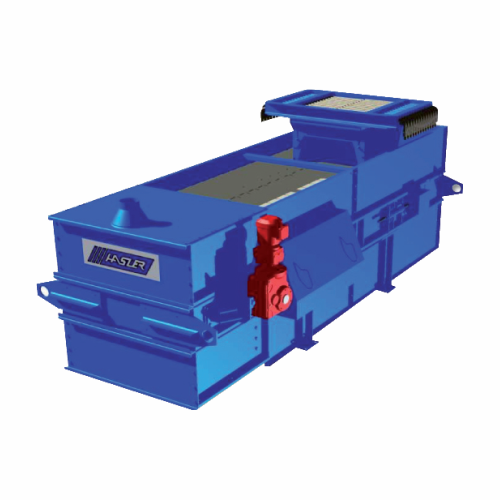

High-temperature extractor weigh belt feeder for clinker

Handle hot, abrasive products like clinker seamlessly with a robust solution that combines the precision of weight measurement with durable materials, ensuring uninterrupted high-flow operations even under extreme temperatures.

Transports and Doses High-Temperature Abrasive Materials

The MAMMUTHUS Clinker Extractor Weigh Feeder from HASLER Group pairs a robust metal apron with precise weight sensing to manage high-temperature, abrasive materials in continuous operations. It integrates dosing and conveying into a compact unit, ideal for cement and heavy industries. Designed for materials like clinker, it operates efficiently in temperatures up to 300°C with optional compressed air cooling. Offering dosing precision within ±1%, the MAMMUTHUS Clinker supports high flow rates in processes requiring exact measurements. Available in multiple widths for versatility, it features double chain traction for high load capacity and durability. Equipped with an impulse sensor for accurate speed monitoring, this feeder enhances integration into automated systems via SCMIII control. Optional enclosure reduces dust emissions, while built-in inspection doors aid in maintenance, ensuring operation reliability and longevity.

Benefits

- Maximizes operational efficiency with precise dosing accuracy of ±1%.

- Handles high temperatures up to 300°C, ensuring reliable operation in demanding environments.

- Reduces equipment footprint and maintenance needs by integrating extraction and weighing.

- Enhances durability with robust metal apron, suited for abrasive materials like clinker.

- Facilitates easy maintenance with accessible inspection doors, minimizing downtime.

- Applications

- Polymers, Amino acids, Hydrometallurgy, Water treatment, Fertilisers, Metals recycling, Minerals processing, Specialty acids, Technical ceramics, Resins, Flue gas desulphurization, Cement

- End products

- Polyethylene sheets, Gypsum for wallboard, Alumina-based ceramics, Epoxy resins, Citric acid, Iron ore concentrate, Npk fertilizers, Nickel sulfate, Clinker, Recycled aluminum bars, Lysine, Desalinated water

- Steps before

- Crushing, Screening, Preheating

- Steps after

- Cooling, Grinding, Storage

- Input ingredients

- clinker, refractory materials, hot products, abrasive products, materials based on clay, bauxite, limestone

- Output ingredients

- accurately dosed hot products, accurately dosed abrasive products, transported cement materials

- Market info

- HASLER Group is known for manufacturing and supplying industrial engineered-to-order (ETO) equipment, specializing in mixing, filtration, and sealing solutions for various industries, with a reputation for quality and innovation in handling challenging process applications.

- Temperature Range

- 200°C to 300°C

- Accuracy

- ±1%

- Apron Width

- Available in four belt widths

- Dosing Type

- Gravimetric

- High Flow Rate

- Yes

- Load Capacity

- High

- Material Type

- Hot and Abrasive

- Automation

- SCMIII Controlled

- Material Flow Management

- Impulse Sensor

- Cooling Option

- Compressed Air

- Chain Traction

- Double

- Working Mechanism

- Metal apron and gravimetric conveyor system

- Temperature Resistance

- 200°C to 300°C

- Material Handling

- Hot and abrasive materials

- Precision Level

- ±1%

- Modularity

- Four apron widths available

- Integration

- Combined extractor and weigh feeder

- Control System

- SCMIII control system

- Continuous Operation

- 24/7 industrial use

- Inspection Features

- Built-in inspection doors

- Automation Level

- Automated dosing system

- Cooling Option

- Compressed air cooling available

- Maintenance Efficiency

- Reduced footprint and maintenance

- Abrasion resistance

- Yes

- Thermal resistance

- 200°C to 300°C

- Corrosive resistance

- High

- Density/particle size

- Compatible with high-density materials

- Compact footprint

- Yes

- Control panel type

- SCMIII control system

- Discharge method

- Metal apron conveyor belt

- Temperature range

- 200–300°C

- Inspection doors

- Yes

- Modular apron widths

- Four available sizes

- Modularity

- Available with four apron widths

- Cooling Option

- Compressed air cooling available

- Control Panel Type

- SCMIII control system

- Integration Possibilities

- SCMIII control system for data and alerts transmission

- Enclosure Options

- Can be fully enclosed to reduce dust emissions

- Scraper Option

- Chain-driven recovery system available

- Material Isolation

- Equipped with a barred gate