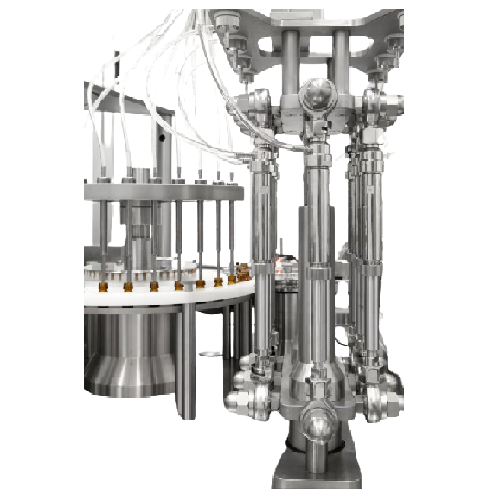

Filling and capping solution for oral liquid products

Achieve precise, high-speed filling and capping of oral liquids with advanced contamination prevention and easy cleaning, ensuring consistent quality and efficiency for high-volume production lines.

Fills and Caps Oral Liquid Products

The RFC8 from Omnia Technologies is a continuous-motion filling and capping machine tailored for the pharmaceutical industry’s oral liquid products. Capable of processing up to 200 bottles per minute, it ensures precision dosing and rapid capping through its innovative tracking sector and multiple capping heads system. This fully automated machine integrates seamlessly into existing production lines, supporting various container formats and sizes. Designed with modularity in mind, it offers compatibility with other equipment and includes Clean-In-Place (CIP) features for efficient, contamination-free maintenance. Constructed with durable materials, the RFC8 meets GMP regulations and can be fitted with AISI 316L stainless steel for higher-grade environments, ensuring both hygiene and longevity in demanding production settings.

Benefits

- Enhances production speed while maintaining dosing accuracy for increased operational efficiency.

- Reduces changeover time with ergonomic design, ensuring quick setup and adaptability to different formats.

- Lowers maintenance costs and extends lifecycle with durable construction and reliable materials.

- Prevents contamination with an easy clean design, maintaining hygiene and quality standards.

- Offers flexibility with modular design, easily integrating with existing systems and accommodating future upgrades.

- Applications

- Syrups, Pharmaceutical liquids, Oral liquid products

- End products

- Antacid solutions, Pediatric syrups, Vitamin supplements, Cough syrups, Herbal tinctures, Liquid cold remedies

- Steps before

- Preparation, Ingredient Mixing, Formulation, Container Selection

- Steps after

- Packaging, Labeling, Quality Inspection, Distribution

- Input ingredients

- oral liquid products, containers, stoppers, caps, cover-caps

- Output ingredients

- filled bottles, capped bottles, capped containers

- Market info

- OMB Italia by Omnia Technologies is known for manufacturing high-precision industrial engineered-to-order equipment, specializing in quality and customized solutions for diverse industrial sectors. Their expertise and reputation underline their commitment to innovation and customer satisfaction.

- Production Speed

- Up to 200 pcs/min

- Automation

- Fully automatic

- Filling Method

- Continuous-motion filling

- Capping Method

- Multiple capping heads

- Compatibility

- Stoppers, caps and cover-caps

- Capping Synchronization

- Same speed as bottles

- Cleaning Method

- CIP on board

- Material

- AISI 316L stainless steel (optional)

- Modular Design

- Yes

- Quick Setup and Changeover

- Yes

- Compatibility with Other Equipment

- Yes

- Ergonomic Design

- Yes

- Lifecycle Support

- Yes

- Working Mechanism

- Continuous-motion

- Integrated Steps

- Filling and Capping

- Automation Level

- Fully Automatic

- CIP/SIP

- CIP on board

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- CIP

- Changeover Time

- Quick Setup and Changeover

- Cleanability

- Easy Clean Design

- Corrosive resistance (e.g. acids)

- AISI 316L stainless steel

- Discharge method

- Screw / press / cork / stopper

- Modular Design

- Yes

- Ergonomic Design

- Yes

- Material choice

- AISI 316L stainless steel

- Integration possibilities

- Compatibility with modular systems

- Control panel type

- Automatic/ Fully automatic

- Environment configuration

- Configurable for high-grade environments

- Optional features

- Equipped with LAF (Laminar Air Flow)