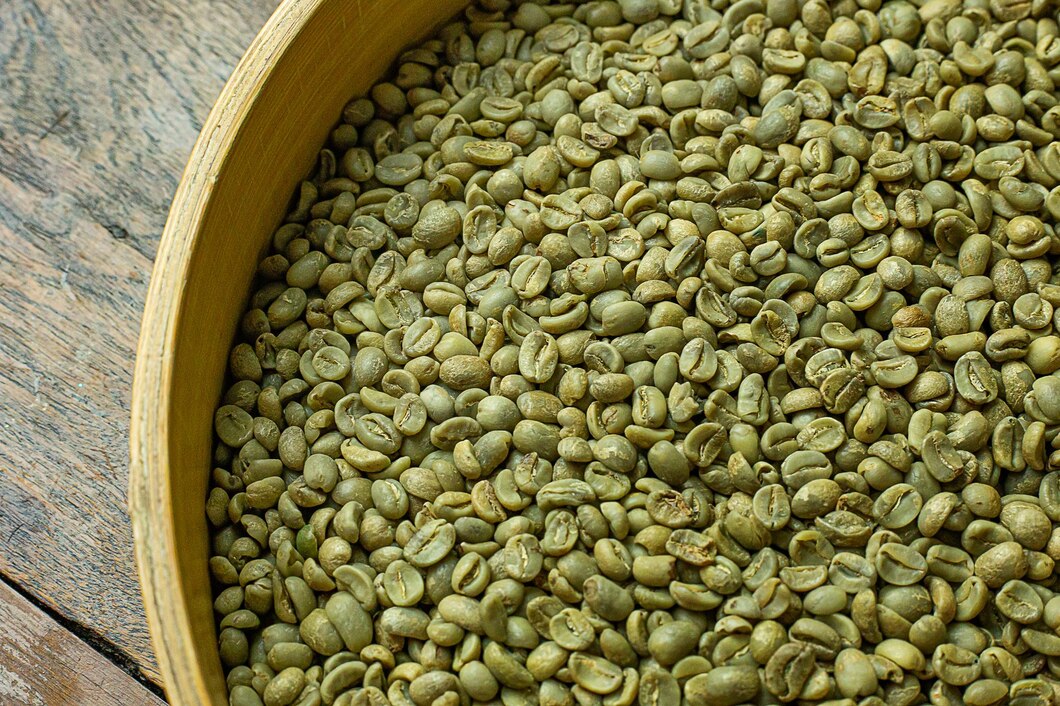

Green coffee intake systems

Streamline your green coffee bean processing with versatile systems that manage intake, conveying, sorting, and cleaning, ensuring high-capacity, efficient, and contamination-free operations for superior coffee quality.

Automates Green Coffee Receiving and Processing

The Petroncini Green Coffee Intake Systems, featuring the IUTHAS model, offer coffee producers and processors a comprehensive solution for seamlessly handling green coffee beans. This equipment is designed to efficiently automate the intake process, handling both bulk and bagged coffee. Its versatile design features telescopic conveyors, tilting stations, and integrated sorting units for a smooth operation. It distinguishes itself with a dual-function reception capability that accommodates both bagged and container-delivered coffee, streamlining operations up to 2 containers per hour.

Petroncini prioritizes dust management with integrated aspiration systems, ensuring a clean and safe processing environment. Capable of handling high-capacity, continuous operations, this system is ideal for large-scale coffee producers and roasters. Constructed with durable materials suitable for food-grade operations, it offers customization options to fit specific production line layouts. The inclusion of state-of-the-art PLC technology facilitates seamless integration with existing processing lines, enhancing operational efficiency and reducing labor demands.

Benefits

- Enhances efficiency by automating the entire coffee intake process.

- Minimizes product loss with integrated dust extraction and collection systems.

- Reduces labor costs through automated operation and integration with existing systems.

- Supports high-capacity operations, handling up to 2 containers per hour.

- Customizable to fit specific production layouts and requirements.

- Applications

- Coffee processing, Green coffee beans, Coffee

- End products

- Green coffee, Green coffee blends, Processed green coffee beans

- Steps before

- Reception, Sorting, Inspection

- Steps after

- Cleaning, Storaging, Conveying

- Input ingredients

- green coffee beans, single bags, bulk container, pallets

- Output ingredients

- clean green coffee beans, hygienically treated coffee, dust-free coffee

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Capacity

- Up to 750 bags/hour

- Container Handling

- Single bag to bulk container

- Automation

- Automated Solutions

- Dust Extraction System

- Superior dust extraction system

- Receiving Station

- Bags and bulk handling

- Integration

- Telescopic conveyor with palletizing robot

- Conveyor System

- Belt conveyor for beans collection

- Tilting System Efficiency

- Improves reception rates

- Automation level

- Fully Automated/PLC Controlled

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- Integrated Dust Extraction System

- Energy efficiency

- Optimized for Bulk Handling

- Changeover time

- Fast Changeover with Integrated Systems

- Handling capacity

- Up to 2 containers/hour

- Intake method

- Bags and Bulk

- Dust control

- Integrated Dust Aspiration System

- System type

- Indoor/Outdoor Receiving System

- Abrasion resistance

- High

- Cleanability

- Easy to clean, CIP compatible

- Corrosive resistance

- Stainless steel construction

- Density/particle size

- 0.5–2.5 g/cm³

- Footprint

- Indoor/Outdoor installation available

- Installation Method

- Underground or on supporting frame

- Hopper Type

- Indoor and outdoor receiving hoppers

- Conveyor Type

- Telescopic conveyor

- Tilting System

- Hydraulic tilting for pallets and containers

- Sorting System

- Integrated sorting unit for bags downstream

- Dust Extraction System

- Superior dust extraction with airflow control

- Receiving Capacity

- Up to 2 containers per hour

- Bags Handling System

- Palletizing/depalletizing robot with bags opening unit

- Indoor/Outdoor Hopper Installation

- Underground/Supporting Frame

- Hopper Capacity

- Single Bag to Bulk Container

- Conveyor Type

- Telescopic/Stationary

- Robot Integration

- Palletizing/Depalletizing

- Bags Opening Unit

- Available

- Sorting Unit Configuration

- Integrated with Tilting Station

- Dust Extraction System

- Integrated

- Container Handling

- Hydraulic Tilting Mechanism

- System Versatility

- Bags and Bulk Coffee

- Belt Conveyor

- Special Design for Bean Collection