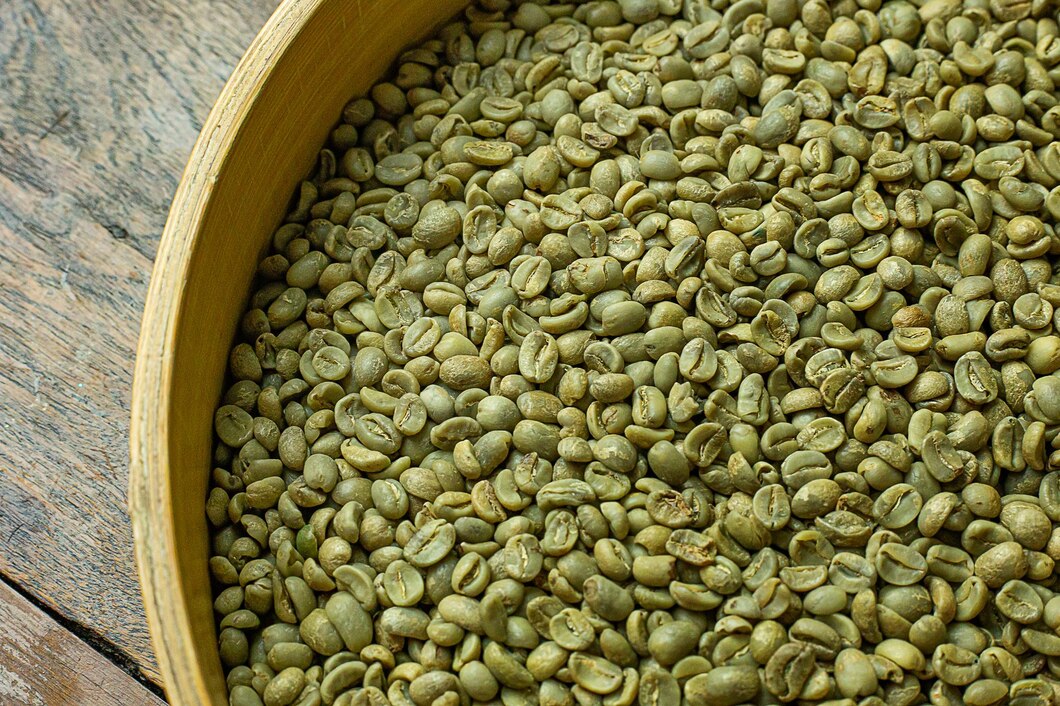

Green coffee handling and conveying systems

Efficiently handle and convey green coffee beans to maintain product integrity and streamline your production line with versatile solutions designed for seamless integration and space-saving performance.

Conveys and Handles Green Coffee Beans

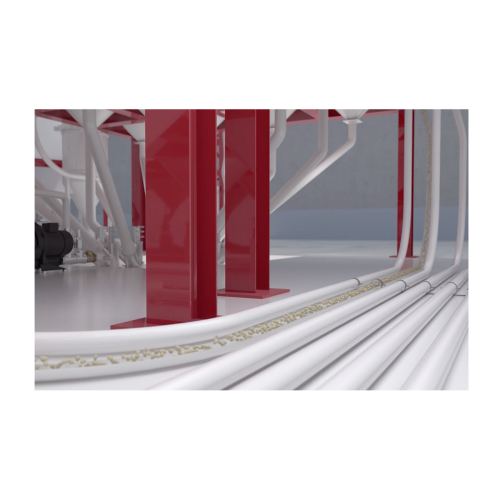

The Green Coffee Handling and Conveying Systems from IMA Coffee Petroncini are engineered to optimize the efficiency of your coffee processing line. These systems employ mechanical and pneumatic conveying methods, including bucket elevators and chain conveyors, designed for seamless integration into continuous, high-speed operations. They handle a variety of tasks, from transporting raw coffee beans to dosing and unloading in coffee production and processing facilities. You can expect hygienic transportation and minimal maintenance with pneumatic systems capable of processing large volumes over long distances. The systems are crafted with hygienic design specifications to prevent contamination and preserve product integrity. With solutions like rotary distributors and special dosing devices, these systems are tailored to the unique needs of coffee producers and food and beverage manufacturers. Designed with flexibility, they can be customized to fit specific plant layouts and are built from materials that ensure longevity and resistance to typical processing challenges.

Benefits

- Enhances operational efficiency by ensuring seamless transition between coffee processing stages.

- Minimizes contamination risks through hygienic design specifications, preserving coffee quality.

- Reduces maintenance costs with durable pneumatic and mechanical conveying systems.

- Maximizes plant layout flexibility, optimizing space and storage capacity.

- Supports high-speed, continuous operations, boosting overall productivity in coffee production.

- Applications

- Coffee processing, Green coffee, Raw coffee beans, Coffee production

- End products

- Coffee grounds, Green coffee beans, Bulk coffee storage, Specialty coffee blends, Unroasted coffee, Coffee silos

- Steps before

- Storage, Raw Coffee Unloading, Dosing

- Steps after

- Roasting, Packaging, Storage Distribution

- Input ingredients

- green coffee beans

- Output ingredients

- processed coffee beans, stored coffee beans

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Conveying Type

- Mechanical / Pneumatic

- Bucket Elevator Suitability

- Vertical / Horizontal

- Handling Type

- Gentle

- Automation

- Automatic product speed control

- Pneumatic Conveying Mode

- Pression / Aspiration

- Dosing Device Type

- LINE-S

- Space Optimization

- Compact footprint

- Working Mechanism

- Mechanical / Pneumatic

- Automation Level

- PLC-controlled / Manual

- Batch vs. Continuous Operation

- Continuous

- Handling Type

- Vertical / Horizontal

- Integrated Steps

- Dosing / Unloading

- Hygienic Design

- Yes

- Product Speed Control

- Automatic

- Space Optimization

- High

- Energy Efficiency

- Maximized

- Maintenance Needs

- Minimum

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Gentle product handling

- Preservation of product integrity

- Product contamination prevention

- Hygienic Design specifications

- Footprint

- Compact, space-saving design

- Discharge method

- Rotary distributors, special dosing devices

- Handling Type

- Vertical and horizontal handling

- Handling Method

- Mechanical and pneumatic conveying

- Conveyor Type

- Bucket elevators, chain conveyors, pneumatic

- Space Optimisation

- LINE-S optimises space for dosing and unloading

- Vertical space savings

- LINE-S design allows additional storage capacity

- Control panel type

- HMI / PLC interface

- Integration possibilities

- Pneumatic, mechanical, bucket elevator

- Space optimisation

- Compact footprint with LINE-S

- Automation level

- Manual / Automatic

- Product unloading type

- Special dosing device