Cip system for small to medium breweries

Ensure consistent craft beer quality with a modular cleaning solution that seamlessly integrates into your brewing process, offering efficient cleaning and sterilization tailored for small to medium brewing operations.

Facilitates Reliable and Efficient Brewery Cleaning

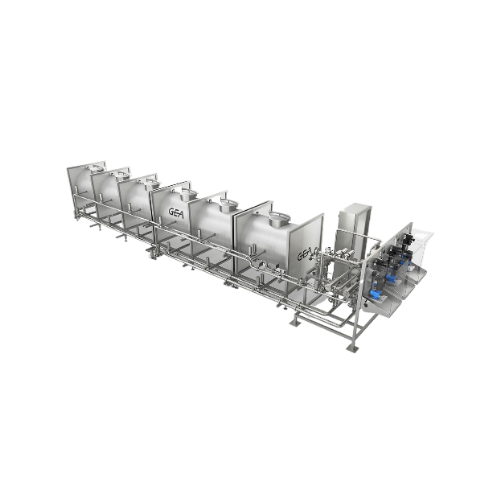

The GEA CIP-STAR® Craft Station is engineered by GEA to optimize cleaning processes within small to medium-sized breweries. This modular Clean-in-Place (CIP) system is specifically designed to streamline the sanitation of brewing equipment, ensuring high product quality and hygiene standards. By utilizing customizable modules, it effectively distributes CIP media across the entire brewery, supporting diverse applications like cleaning, sterilization, and heating.

With its skidded design and horizontal tanks, the GEA CIP-STAR® minimizes space requirements and simplifies installation. It includes three detergent dosing pumps to allow flexible use of cleaning agents such as caustics, acids, and disinfectants. The system features two separate CIP feed lines for dedicated cold and hot cleaning media, with an integrated heat exchanger for efficient heating of caustics. Offering capacities with tank modules ranging from 10 to 15 hectoliters, it supports a broad spectrum of beer production processes, from lagers to IPAs.

The GEA CIP-STAR® is also designed for easy integration, with options for stand-alone control systems or full integration into the GEA CODEX® system, ensuring seamless operation within your existing infrastructure. With a focus on automation and energy efficiency, the system operates on a connected load of 10 kW, providing both operational reliability and cost effectiveness for craft brewers seeking a robust cleaning solution.

Benefits

- Enhances cleaning efficiency and ensures consistent beer quality.

- Customizes to specific cleaning needs with modular tank options.

- Saves space and reduces installation effort with compact skidded design.

- Minimizes downtime with dedicated CIP lines for simultaneous cleaning operations.

- Lowers energy use with integrated heat exchanger for efficient caustic heating.

- Applications

- Craft beer, Beverage, Beer production, Brewing, Alcoholic beverages

- End products

- Pilsner, Lager, Pale ale, Ipa (india pale ale), Stout, Wheat beer, Porter

- Steps before

- Brewing, Fermentation

- Steps after

- Product Quality Assurance, Packaging, Distribution

- Input ingredients

- cleaning media, detergents, caustics, acid, disinfectant, hot cleaning media, cold cleaning media, steam

- Output ingredients

- cleaned machinery, cleaned tanks, cleaned pipe network

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Flowrate of CIP Feed,hot media

- 18 cbm/h

- Flowrate of CIP Feed,cold media

- 13 cbm/h

- Steam Connection at CIP Heater

- 250 kg/h

- Connected Load,3-phase power

- 10 kW

- Footprint of Process Module

- 2, 200 x 2, 600 mm

- Footprint of per tank module

- 2, 000 x 2, 000 mm

- Tank sizes

- 10 hl or 15 hl

- Detergent dosing pumps

- 3 pumps for caustics, acid, and disinfectant

- CIP buffer tanks

- 1, 2, or 3 available

- Heat exchanger integration

- Batch or inline heating of caustics

- CIP feed lines

- Two separated lines for cold and hot media

- Working mechanism

- Pre-assembled process unit

- Integrated Steps

- Hot and cold cleaning media separation

- CIP Principles

- Modular design for customization

- Batch vs inline flow

- Batch or inline heating

- Automation level

- Stand-alone control system or GEA CODEX® integration

- Cleaning method

- CIP

- Changeover time

- Easy customization by combining modules

- Energy efficiency

- Compact footprint for low energy usage

- Machine Footprint

- Process Module

- Per Tank Module

- 2, 000 x 2, 000 mm

- Tank Shape and Size

- CIP Buffer Tanks

- Tank Configuration

- 1, 2, or 3 CIP Buffer Tanks

- Tank Insulation

- Insulated or Non-insulated

- Feed/Discharge Method

- Skidded Design with Multiple Feed and Return Lines

- Customization

- Modular Design with Main Process Module and Tank Modules

- Skid Design

- Compact Footprint with Horizontal Tanks

- Module customization

- Modular design for specific cleaning requirements

- Tanks configuration

- 1, 2, or 3 CIP buffer tanks

- 10 hl or 15 hl volume

- Insulation choice

- Insulated or non-insulated tanks

- Control system integration

- Stand-alone control or integration into GEA CODEX® system