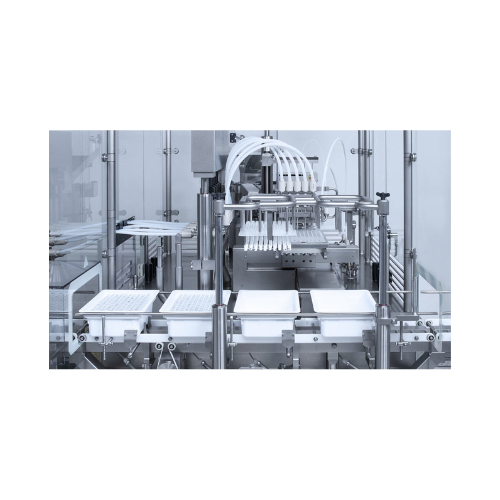

Filling and closing solution for nested containers

Streamline your vial, cartridge, and syringe production with precise dosing and secure closing while minimizing air entrapment and contamination risks, ensuring high-quality injectable pharmaceuticals.

Fills and Closes Nested Containers with Precision

The SFM Series from Bausch+Ströbel excels in efficiently filling and closing nested containers like vials, cartridges, and disposable syringes. Designed with pharmaceutical production in mind, these machines integrate seamlessly into your line, offering both fully automatic and manual feeding options for versatility. This equipment stands out with its ability to employ rotary piston, peristaltic, or time-pressure dosing systems, depending on the specific needs of your biopharmaceutical operations. Critical for producing vaccines, blood plasma products, and injectable medications, the SFM Series ensures precision with its vacuum-assisted filling that minimizes air entrapment, thus enhancing product integrity.

Capable of processing up to 60,000 items per hour, these machines are built with process reliability in mind, incorporating in-process control and vacuum-assisted closures. The units maintain production parameters with ease and allow for short set-up times. Energy efficiency is heightened through optimized laminar airflows and reduced particle generation when sealing, contributing to both cost reduction and product safety.

Constructed for compliance with DIN, GMP, and FDA standards, the SFM machines support CIP/SIP systems for thorough, contamination-free cleaning, aligning with stringent pharmaceutical regulations. With additional options like RABS and isolators for aseptic environments, the SFM Series ensures your production remains consistent and compliant. Customizations and configurations are supported, backed by Bausch+Ströbel’s comprehensive engineering assistance.

Benefits

- Increases production efficiency with high-speed filling and closing up to 60,000 items per hour.

- Minimizes contamination risk through vacuum-assisted filling and advanced RABS/isolator options.

- Ensures product integrity with precise dosing technologies, reducing air entrapment in syringes.

- Simplifies cleaning and maintenance with CIP/SIP-compatible systems, saving time and resources.

- Meets stringent regulatory requirements with GMP and FDA-compliant design.

- Applications

- Disposable syringes, Pharmaceutical liquid formulations, Vials, Biopharmaceuticals, Cartridges, Injectable pharmaceuticals

- End products

- Vaccines, Erythropoietin, Blood plasma products, Pain relief injections, Insulin, Monoclonal antibodies, Vitamin injections, Heparin solutions, Growth hormones, Pre-filled syringe medications

- Steps before

- Purification, Component preparation, Container sterilization

- Steps after

- Capping, Labeling, Final inspection, Packaging

- Input ingredients

- nested containers, vials, cartridges, disposable syringes, pharmaceutical liquid products, gas for flushing

- Output ingredients

- filled vials, filled cartridges, filled disposable syringes, vacuum-assisted filled syringes, closed containers, entrapped air-free syringes

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- Up to 60, 000 items/h

- Nesting Size

- 0.5 - 50 ml

- Dosing System

- Rotary piston pumps

- Alternative Dosing Systems

- Peristaltic pumps, time-pressure dosing system

- Vacuum-assisted Dosing

- Yes

- Filling and Closing

- Fully automatic

- Gas Flushing

- Controlled amount during filling and closing

- SIP/CIP Compatibility

- SIP/CIP-compatible dosing components

- Cleanroom Compatibility

- Yes

- Automation

- Fully automatic

- Set-up Time

- Short

- Laminar Air Flow

- Optimal design

- Output (SFM5110)

- Up to 11, 400 items/h

- Output (SFM5072)

- Up to 60, 000 items/h

- Output (SFM5105)

- Up to 4, 300 items/h

- Low-Particle Closure Feed

- Yes

- In-Process Control

- Fully automatic

- Qualification

- IQ/OQ

- Working mechanism

- Rotary piston pumps, peristaltic pumps, time-pressure system

- Integrated steps

- Filling, closing, vacuum-assisted dosing

- CIP/SIP

- SIP-compatible dosing components

- Batch vs. continuous operation

- Fully automatic

- Changeover time

- Short set-up time

- Automation level

- Fully automatic

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Control panel type

- Centralized operation

- Discharge method

- Fully automatic closing

- Container type

- Nested containers (vials, cartridges, syringes)

- Machine footprint

- Compact design

- Control panel type

- Centralized operation

- Compact footprint

- Compact design

- Discharge method

- Automatic

- Alternative dosing systems

- Peristaltic pumps, time-pressure

- Vacuum-assisted dosing

- Available

- Barrier systems

- RABS and cleanroom isolator

- Filling volume

- 0.5 - 50 ml