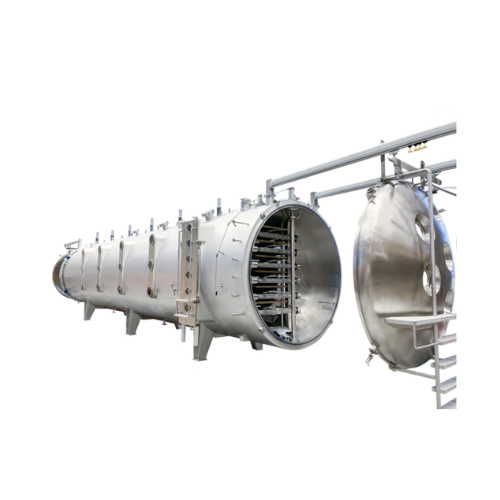

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products with this belt dryer, ensuring gentle handling while maintaining flavor integrity for freeze-dried food, beverages, and pharmaceuticals.

Continuously Freeze-Dries Heat-Sensitive Products

The DryBand Lyo from Bucher Unipektin is a cutting-edge belt dryer designed for continuous freeze-drying applications, addressing the complexities of processing heat-sensitive products. By employing a unique vacuum belt system, this equipment ensures gentle drying without oxidation, preserving the integrity and flavor of products like instant coffee, freeze-dried fruits and vegetables, and lyophilized pharmaceuticals. Capable of processing a wide range of products, from solid and granules to powders, it accommodates a throughput of 2 to 4000 kg/h. With independent heating zones and patented radiant plates, it achieves efficient moisture removal, while the cooling zone option provides additional control over end-product quality. Fully automated with integrated CIP systems, this dryer minimizes manual intervention and ensures operational hygiene. Constructed for reliability, it supports diverse industries ranging from food and beverage to pharmaceuticals, offering tailored engineering to meet specific production requirements.

Benefits

- Enhances product quality with gentle freeze-drying to maintain natural flavors and textures.

- Minimizes energy consumption through efficient heating systems and vacuum operation.

- Reduces the risk of contamination with a fully closed system and hygienic design.

- Increases operational efficiency with continuous, fully automated processing.

- Supports clean label promotion by eliminating the need for drying carriers.

- Applications

- Seafood, Infant nutrition, Meat, Coffee, Fruits, Enzymes, Vegetables, Probiotics, Pharmaceuticals

- End products

- Freeze-dried peas, Freeze-dried shrimp, Freeze-dried strawberries, Lyophilized pharmaceuticals, Probiotic capsules, Enzyme powders, Freeze-dried chicken pieces, Infant formula, Instant coffee granules

- Steps before

- Pre-drying, Freezing, Grinding (for powders)

- Steps after

- Cooling, Discharging, Packing

- Input ingredients

- coffee, pre-dried fruits, frozen fruits, pre-dried vegetables, frozen vegetables, meat pieces, seafood pieces, granules, probiotics, enzymes, infant nutrition

- Output ingredients

- freeze-dried coffee, freeze-dried fruits, freeze-dried vegetables, freeze-dried meat, freeze-dried seafood, free-flowing powders, free-flowing granules, dried probiotics, dried enzymes, dried infant nutrition

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Feed rate

- 2 to 4000 kg/h

- Heating,cooling surface

- 0.2 to 325 m²

- Heating range

- 20 to 180 °C

- Vacuum range

- 0.5 to 50 mbar (abs.)

- Automation

- Fully automated operation

- Drying type

- Continuous freeze-drying (lyophilisation)

- Design

- Closed system with hygienic design

- Energy consumption

- Low

- Working mechanism

- Vacuum belt dryer with multistage desublimation

- Integrated steps

- Feeding, drying, cooling

- Automation level

- Fully automated operation

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Fully automated cleaning

- Energy efficiency

- Low energy consumption

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable

- Discharge method

- Intermediate hopper with automatic airlocks

- Feed method

- Hopper with unique dosing system

- Heating surface area

- 0.2 to 325m²

- Heating range

- 20 to 180 °C

- Vacuum range

- 0.5 to 50 mbar (abs.)

- Construction type

- Closed system with hygienic design

- Dosing System

- Unique dosing system

- Heating Zones

- Independent heated zones

- Cooling Zone Option

- Last zone can be designed as cooling

- Automation Level

- Fully automated operation and cleaning

- Vacuum System

- Single stage or multistage desublimation/vacuum system

- Integration of Radiant Plates

- Additional radiant plates (patented)

- Energy Efficiency

- Low energy consumption

- Hopper Feeding

- Doses into an intermediate chamber