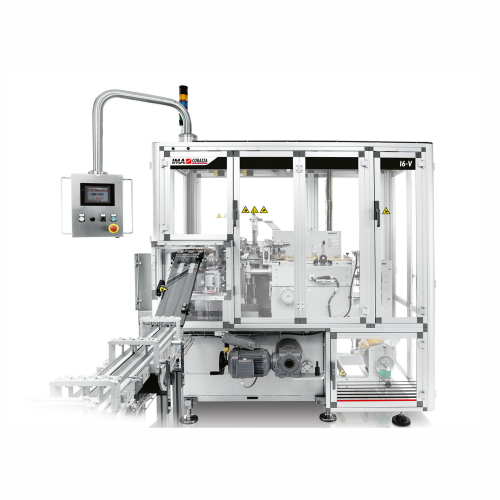

Pressed soup cube bottom fold wrapper

Optimize your packaging line with high-speed wrapping machines designed for precision folding and sealing of solid products like soup cubes and tablets, ensuring efficiency and sustainability in every operation.

Wraps Soup Cubes and Tablets Efficiently

The I Series – Bottom Fold Wrapping Machine from IMA Group is tailored for high-speed packaging of soup cubes and tablets. It features a fully mechanical execution that guarantees long-lasting reliability and straightforward maintenance. This machine uses optimized motorization, sharing kinetic energy among modules to minimize power waste, making it ideal for continuous operations. Whether handling bouillon cubes, herbal supplement tablets, or confectionery items, this equipment seamlessly integrates with existing production lines and accommodates up to 800 portions per minute. It offers versatility in material usage, supporting a range of packaging options, such as Alufoil and thermo-welding aluminum. With automated features like print centering and vibration elimination, it ensures precision and consistency. The machine’s design supports easy cleaning and includes options for recyclable packaging, aligning with sustainable practices.

Benefits

- Enhances production efficiency with high-speed wrapping up to 800 portions per minute.

- Minimizes energy costs by sharing kinetic energy across modules, reducing power waste.

- Ensures precise wrapping with automated print centering and vibration elimination.

- Supports sustainable packaging with options for recyclable materials.

- Simplifies maintenance with a fully mechanical design and easy-to-clean features.

- Applications

- Confectionery, Soup cubes, Food products, Tablets

- End products

- Bouillon cubes, Vitamin tablets, Stock cubes, Energy tablets, Herbal supplement tablets, Compressed snack cubes, Chewable candies, Soft confectionery tablets, Nutrient-dense food bars

- Steps before

- Dosing, Pressing

- Steps after

- Packing

- Input ingredients

- pressed soup cubes, tablet shapes, double cube shapes

- Output ingredients

- packaged soup cubes, wrapped tablets, wrapped double cubes

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Capacity

- Up to 800 portions/min for I6 and I6V models

- Capacity

- Up to 550 portions/min for IDP model

- Capacity

- Up to 500 portions/min for IDP/S model

- Speed

- Up to 800 ppm

- Compressed Air Usage

- 120 Nl/min (6 bar) for IDP and IDP/S models

- Compressed Air Usage

- 150 Nl/min (6 bar) for I6 and I6V models

- Weight

- Approximately 2, 000 Kg for IDP and IDP/S models

- Weight

- Approximately 1, 500 Kg for I6 and I6V models

- Power Specifications

- 3P x 400 Volt 50 Hz – 10 Amp for IDP model

- Power Specifications

- P x 400 Volt 50 Hz – 10 Amp for IDP/S model

- Power Specifications

- 3P x 400 Volt 50 Hz – 12 Amp for I6 and I6V models

- Automation

- Brushless motor control with print centring device

- Packaging Material Compatibility

- Alufoil, AluBOPP, BOPP, thermo-welding aluminium, coupled aluminium OPP

- Sealing Method

- Side and lower sealing sections with automatic ejection

- Automation level

- PLC controlled

- Changeover time

- Quick changeover

- CIP/SIP

- Not specified

- Energy efficiency

- Kinetic energy recovery

- Batch vs. continuous operation

- Continuous operation

- Packaging Material

- Alufoil

- Packaging Material

- AluBOPP

- Packaging Material

- BOPP

- Packaging Material

- Thermo-welding aluminium

- Packaging Material

- Coupled aluminium OPP

- Recyclability

- Sustainable and recyclable materials

- Cube Size

- Customizable upon request

- Machine footprint

- Compact

- Machine weight

- 1, 500 - 2, 000 Kg Approx.

- Shape size

- Tablet / Cube / Double Cube

- Box dimensions (min ÷ max)

- A

- Discharge method

- Automatic product ejection

- Wrapping type

- Bottom fold

- Control panel type

- Brushless motor-controlled

- Easy opening feature

- Cube and bar size

- Motorization

- Kinetic energy sharing

- Sustainable packaging

- Recyclable materials

- Print centring device

- Brushless motor control

- Special device on wrapping section

- Vibration elimination