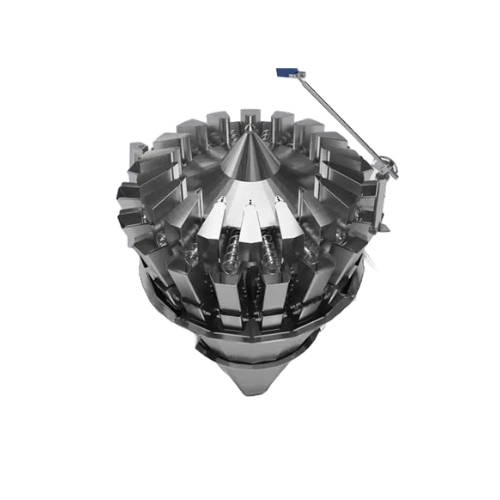

Multihead weigher with screw feeding for sticky products

Achieve exceptional precision and reduce giveaway costs in handling sticky, wet products with a patented screw-feeding system, designed to optimize weighing accuracy for diverse food production lines.

Weighs and Feeds Sticky and Wet Products Accurately

The Multihead Weigher with Screw Feeding from Cabinplant is engineered to excel in handling sticky and wet products across industries like fish, seafood, meat, poultry, and convenience foods. Its patented screw feeding principle distinguishes it by delivering high weighing accuracy while minimizing product giveaway. This weigher is ideal for applications involving shrimp, tuna chunks, and ready-meal pasta dishes, effectively managing both solid and slurry products.

Operating under continuous high-speed conditions, it features a rotating cone on top that ensures optimal product distribution to each pan. This weigher is capable of single or multiple weighing setups, accommodating diverse production needs. Its automatic screw dosing system adjusts in real-time, enhancing weighing precision and efficiency.

Built with hygienic design considerations, it promises easy cleaning and maintenance, making it a reliable addition to any processing or packaging line. Additionally, the weigher integrates seamlessly into automation systems, supported by PLC controls for efficient process management. With models custom-designed to meet specific requirements, it offers adaptability in pan size and screw feeder configurations, ensuring it fits perfectly into your production environment.

Benefits

- Enhances weighing precision, minimizing product giveaway and reducing material costs.

- Supports high-speed operations, thereby increasing overall production efficiency.

- Enables seamless integration into automated lines, reducing manual intervention and associated labor costs.

- Designed for easy cleaning, ensuring minimal downtime and maintaining hygienic standards.

- Accommodates a wide range of sticky and wet products, increasing versatility across processing tasks.

- Applications

- Seafood, Dairy food, Convenience food, Pet food, Meat, Fruits, Vegetables, Poultry, Fish

- End products

- Chicken nuggets, Dog kibble, Beef strips, Cat treats, Shrimp, Tuna chunks, Turkey slices, Yogurt cups, Diced apples, Ready-meal pasta dishes, Processed cheese cubes, Vegetable stir-fry mixes, Berry medleys

- Steps before

- Preparation, Mixing, Thawing, Pre-cooking

- Steps after

- Packing, Distribution, Marinating, Heat treatment

- Input ingredients

- wet products, sticky products, fish, seafood, meat, poultry, fruit, vegetables, convenience food, fresh fish, fillets, pasta

- Output ingredients

- portioned wet products, portioned sticky products, portioned fish, portioned seafood, portioned meat, portioned poultry, portioned fruit, portioned vegetables, portioned convenience food

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Type of weighing

- Single or multiple weighing

- Type of weighing

- Flow weighing

- Type of weighing

- Floating set-point weighing

- Type of weighing

- Single dynamic weighing (SDW)

- Type of weighing

- Dual dynamic weighing

- Feed type

- Wet / Sticky products

- Feeding method

- Screw feeding

- Accuracy

- High weighing accuracy

- Automation

- Automatic screw dosing time

- Pan size

- Various sizes available

- Number of heads

- 10/12/14/18/20/24/28/32

- Continuous weighing

- Yes

- Rotating cone

- Yes

- Screw dosing time

- Automatic adjustment

- Rollers integration

- Available for long products

- Hygienic design

- Yes

- Noise level

- Minimum

- Maintenance

- Minimum

- Easy cleaning

- Yes

- Configuration flexibility

- Wide range of models

- Working mechanism

- Screw feeding

- Integrated steps

- Screw dosing and rotating cones

- Batch vs. continuous operation

- Continuous weighing

- Cleaning method

- Hygienic design

- Changeover time

- Minimal due to flexible configuration

- Automation level

- Automatic with sensor gates

- CIP/SIP

- Easy cleaning

- Energy efficiency

- High due to precise dosing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type handling

- Fish, Seafood, Meat, Poultry, Vegetables, Convenience Food

- Machine footprint

- Varies by model

- Pan size

- 10/12, 14/18/20, 24/28

- Screw feeder

- Available in multiple sizes

- Rotating cone

- Included on top

- Rollers

- Can be integrated

- Control panel type

- Automated controls

- Screw feeder configuration

- Customizable

- Number of heads

- 10/12/14/18/20/24/28

- Pan size

- Varies

- Control panel type

- Customizable

- Integration possibilities

- High