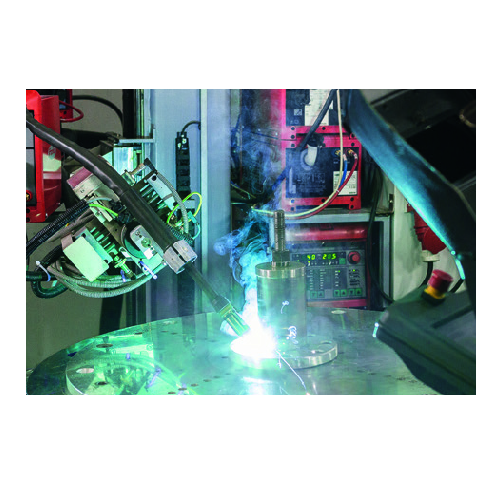

Traditionally welded silos for constrained installation sites

Ideal for facilities with limited space, these traditionally welded silos offer durability and flexibility, supporting diverse production requirements from storage to precise material handling.

Stores and Discharges Materials Efficiently

The Weld-Tec ZSD from Zeppelin Systems is designed for industries requiring durable and reliable storage solutions. These traditionally welded silos excel in space-constrained, temperature-sensitive environments, ideal for applications in the rubber, food, and plastics sectors. Known for their strong construction, they ensure precise material discharge and storage. The silos seamlessly integrate into production lines, handling diverse product types like solids, powders, and granules with ease. Each unit can be tailored to meet specific operational needs, ensuring optimal performance and compliance with industry standards. Constructed from robust materials, they offer superior corrosion resistance, extending their service life and reducing maintenance requirements.

Benefits

- Optimizes space utilization in constrained environments.

- Ensures precise material discharge, enhancing process efficiency.

- Offers corrosion-resistant construction for extended durability.

- Integration-ready for seamless production line adaptation.

- Customizable design meets specific industry and process requirements.

- Applications

- Chemicals, Plastics, Food industry, Rubber and tire industry

- End products

- Food-grade additives, Detergents, Plastic pellets, Paint additives, Tires, Baking mix, Yogurt, Plastic containers, Rubber gaskets, Pvc compounds, Salad dressing

- Steps before

- Design, Engineering, Component Selection

- Steps after

- Quality Assurance, Installation, Integration

- Input ingredients

- Output ingredients

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Automation

- Manual / Auto

- Installation type

- Welded

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Automation level

- Manual / PLC / SCADA

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Installation Capacity

- Smaller capacities

- Tank shape

- Vertical cylinder

- Tank size

- Variable, depending on customer requirements

- Discharge method

- Bottom discharge

- Compact footprint

- Yes, suitable for closer installation sites

- Welding type

- Traditional welding

- Customization

- Designed for specific process or temperature requirements

- Control panel type

- PLC / HMI / SCADA

- Integration possibilities

- Existing systems / new setups

- Custom designs

- Site-specific requirements

- Size,capacity

- Customizable

- Material type

- Steel / Aluminum / Custom

- Temperature management

- Design-specific customizations

- Fixture adaptations

- Specific blending requirements