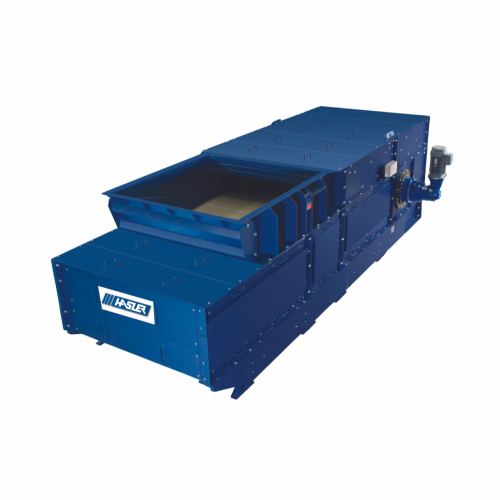

High flow rate extractor weigh feeder for cement and mining

Streamline high-capacity material flow and precise dosing of dense, moisture-rich materials like clay and gypsum with an integrated system designed for demanding industrial processes, ensuring optimal consistency and reduced operational footprint.

Extracts and Measures High-Flow Bulk Materials

The MAMMUTHUS 2000 from HASLER Group combines metal apron extraction and precise weighing in a single platform, tailored for handling high-density materials with up to 750 m³/hour flow rate. Ideal for operations in cement, fertilizers, and metals recycling industries, it ensures stability and ±1% dosing accuracy. Equipped with reinforced steel and a robust chain system, it endures harsh environments in continuous automated processes. The integrated PLC system facilitates seamless integration with existing production lines and offers reliable, real-time process adjustment. Its modular design features various apron lengths to fit diverse industrial requirements, and the built-in inspection doors simplify maintenance, requiring only annual checks.

Benefits

- Ensures precise material dosing, reducing overuse and waste.

- Supports high-density material flow rates, enhancing production capacity.

- Operates reliably under harsh conditions, minimizing maintenance interruptions.

- Modular design adapts to specific process requirements, offering flexibility.

- Integrated automation optimizes process control and reduces manual oversight.

- Applications

- Polymers, Hydrometallurgy, Water treatment, Fertilisers, Metals recycling, Minerals processing, Amino, Technical ceramics, Specialty acids, Resins, Flue gas desulphurization, Cement

- End products

- Polyethylene, Epoxy resins, Aluminum ingots, Potable water, Glutamic acid, Zirconium dioxide, Alumina, Clinker, Gypsum, Urea, Bauxite, Citric acid

- Steps before

- Mining, Extraction, Crushing, Material Loading, Storage

- Steps after

- Dosing, Material Transport, Processing, Packaging, Distribution

- Input ingredients

- clay, gypsum, limestone, high-density materials, materials with high particle size, humid materials

- Output ingredients

- dosed materials, transported materials, extracted materials

- Market info

- HASLER Group is known for manufacturing and supplying industrial engineered-to-order (ETO) equipment, specializing in mixing, filtration, and sealing solutions for various industries, with a reputation for quality and innovation in handling challenging process applications.

- Flow rate capacity

- Up to 750 m³/hour

- Accuracy

- ±1%

- Material Transport

- Clay, Gypsum, Limestone

- Load Capacity

- High load capacity

- Design Type

- Metal apron and belt feeder

- Chain System

- Double/triple chain system

- Automation

- Automated dosing system

- Construction Material

- Reinforced steel plates

- Drive System

- Geared motor with impulse sensor

- Modularity

- Available with several apron lengths

- Inspection,Maintenance

- Built-in inspection doors

- Working mechanism

- Metal apron extractor combined with belt feeder

- Integrated steps

- Extraction, dosing, transporting

- Automation level

- Automated dosing system with controller

- Batch vs. continuous operation

- Continuous

- Changeover time

- Simple maintenance with annual checks

- CIP/SIP

- Not applicable

- Cleaning method

- Inspection doors for maintenance

- Energy efficiency

- High due to reduced friction design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Apron length

- Variable

- Discharge method

- Metal apron conveyor belt

- Equipment composition

- Metal apron with reinforced steel plates

- Control panel type

- SCMIII control system

- Control panel type

- SCMIII PDU console

- Modular design

- Several apron lengths available

- Integration possibilities

- SCMIII material flow control system

- Inspection doors

- Integrated

- Index passage detector

- Included