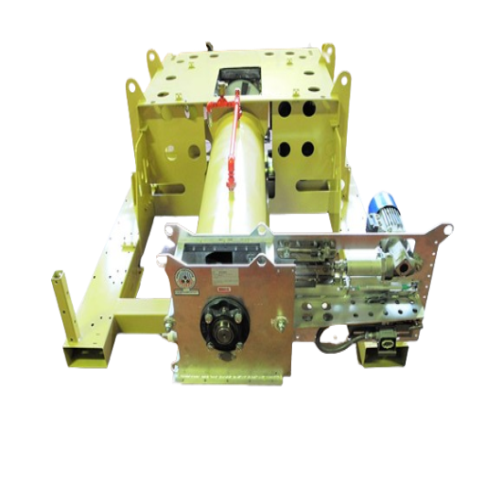

Dosing feeder for coffee production

Streamline your coffee production with precision control, ensuring consistent packing levels and optimal compaction for diverse coffee bean and ground products, all while maintaining an uninterrupted, automated workflow.

Ensures Precision Dosing and Vacuum Packing

The Dosing Feeder from Scolari Engineering is designed to enhance coffee production lines, providing precise dosing and vacuum packing solutions. It utilizes a mechanical vibrator and pneumatic shutter system to maintain consistent levels in the packing hopper, ensuring seamless operation in packaging roasted and ground coffee products. This equipment is essential for producing unflavored roasted beans, espresso grounds, and specialty blends. Featuring continuous, automated operations, it integrates easily into existing production lines, optimizing efficiency for coffee roasters and packaging companies. This robust feeder operates in both the processing and packaging stages, accommodating substantial throughput with consistent performance and minimal maintenance.

Benefits

- Enhances precision in coffee dosing, reducing waste and ensuring product consistency.

- Streamlines integration with existing production lines, optimizing operational efficiency.

- Minimizes labor costs through automated, continuous operation.

- Provides reliable performance with minimal maintenance requirements.

- Supports a wide range of coffee products, accommodating diverse production needs.

- Applications

- Green coffee, Ground coffee, Coffee beans, Roasted coffee

- End products

- Flavored coffee beans, Blended coffee beans, Unflavored roasted coffee beans, Specialty coffee blends, Filter coffee grounds, Espresso coffee grounds, Instant coffee granules, Organic coffee grounds

- Steps before

- Roasting, Transport, Chaff removal

- Steps after

- Vacuum packing, Level monitoring, Robotized end-line packaging

- Input ingredients

- green coffee, roasted coffee, ground coffee, chaff

- Output ingredients

- packaged coffee, vacuum packed coffee, chaff compacted

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Packaging type

- Vacuum packing

- Feeding mechanism

- Mechanically vibrated tanks

- Shutter control

- Pneumatic shutter

- Level control

- Level indicator

- Supporting structure

- Included

- Transportation method

- Chaff cyclones and compactors

- Working mechanism

- Vacuum packing with mechanical vibrator

- Automation level

- Pneumatic shutter with level control

- Integrated steps

- Bean packing, chaff removal

- Density/particle size

- Coffee beans, chaff, powder

- Filling purpose

- Coffee packing

- Material compatibility

- Green / roasted coffee beans

- Machine Footprint

- Compact

- Tank Size

- Varies based on model

- Feed/Discharge Method

- Mechanical Vibrator / Pneumatic Shutter

- Supporting Structure

- Includes hopper support

- Control Panel Type

- Integrated

- Integration possibilities

- With vacuum packing systems

- Pneumatic system

- Shutter with pneumatic control