Hygienic dispenser for precise dosing in food and cosmetics

Achieve precise dosing and application of high-viscosity liquids with exceptional hygiene standards, perfect for enhancing the quality and consistency of your food and cosmetic products in semi-automatic and fully automatic production lines.

Dispenses and Applies High-Viscosity Liquids

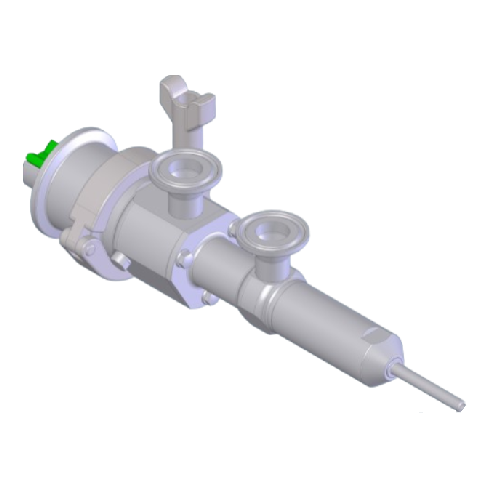

The ViscoTec Hygienic Dispenser VHD is designed to tackle precision dosing challenges in the food, cosmetics, and pharmaceutical industries. Built upon ViscoTec’s renowned endless piston principle, this dispenser ensures precise delivery of high-viscosity liquids, such as chocolate truffles and medicinal ointments. Suitable for semi-automatic and fully automatic operations, it seamlessly integrates into production lines to deliver micro doses with high accuracy and meets stringent hygiene standards akin to the pharmaceutical sector.

This dispenser excels in applications requiring meticulous control, from decorative cake toppings to the formulation of foundation creams. Its adjustable suckback feature guarantees clean dosing, minimizing waste and ensuring consistency. The VHD is constructed to support Industry 4.0 initiatives, offering adaptability for customization and process individualization. Additionally, it is compliant with GMP standards, making it ideal for sensitive production environments in the pharmaceutical and cosmetics fields. With options to integrate into existing processing and final conditioning systems, the ViscoTec VHD ensures both efficiency and reliability in high-demand industrial applications.

Benefits

- Ensures precise dosing to minimize waste and enhance product consistency.

- Adapts easily to existing production lines, supporting seamless integration.

- Meets strict hygiene standards, reducing contamination risks.

- Facilitates customization with adaptable dispensing for personalized product batches.

- Complies with GMP standards, ensuring suitability for regulated industries.

- Applications

- Food, Chocolate, Decorative finishes, Cosmetics, High-viscosity liquids, Complex cosmetic products, Icing, Pharmaceuticals

- End products

- Chocolate truffles, Lip balms, Flavored yogurt, Decorative cake toppings, Hair gels, Medicinal ointments, Foundation creams, Custard creams, Fondant decorations

- Steps before

- Ingredient Mixing, Material Preparation

- Steps after

- Quality Control, Packaging, Labeling

- Input ingredients

- high-viscosity liquids, micro doses, complex cosmetic products, icing, chocolate

- Output ingredients

- precision doses, customised food applications, decorative finishes

- Market info

- Visco Tec is known for its precision dispensing and dosing technology, specializing in equipment for viscoelastic fluids, offering reliable, high-quality solutions for industries like pharmaceuticals, food, cosmetics, and general manufacturing, renowned for engineering excellence and innovation.

- Accuracy

- High precision in micro doses

- Automation

- Semi-automatic and fully automatic

- Dosing type

- Volumetric

- Compliance

- Pharmaceutical hygiene standards

- Viscosity handling

- High-viscosity liquids

- Suckback feature

- Adjustable

- Working Mechanism

- Endless Piston Principle

- Automation Level

- Semi-automatic / Fully automatic

- Compliance to Hygiene Standards

- Pharmaceutical-grade hygiene

- Micro Dosing Capabilities

- Yes

- High Viscosity Liquid Handling

- Yes

- Individualization Support

- Industry 4.0 compatible

- CIP/SIP

- CIP

- Batch vs. Continuous Operation

- Inline Continuous

- Biological compatibility

- Pharmaceutical-grade

- Cleanability

- High hygienic standards

- Corrosive resistance (e.g. acids)

- High-viscosity liquids

- Discharge method

- Precision dosing, endless piston principle

- Compact footprint

- Yes, suitable for implementation on production lines

- Control panel type

- Automation compatible for Industry 4.0

- Dosing Integration

- Inline production lines

- Micro dosing capability

- Yes

- Control System Compatibility

- Industry 4.0 ready

- Hygienic Design

- Pharmaceutical grade

- Viscosity Range Handling

- High-viscosity liquids