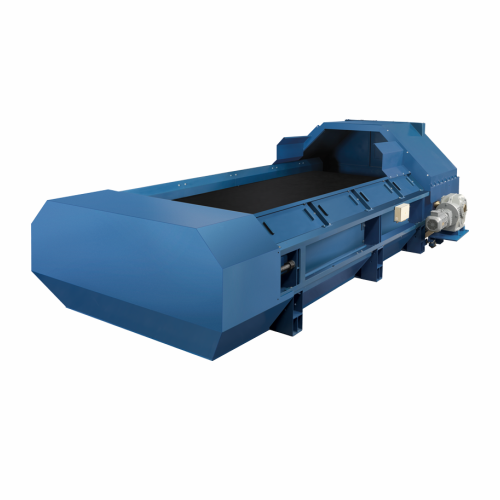

High-speed industrial belt feeder for granular materials

Achieve precise and consistent material dosing in high-flow environments with a robust belt feeder designed for continuous operation, ensuring optimal performance and integration into your production line.

Ensures Precise Dosing and High-Flow Material Handling

The GI GRAVIT from HASLER Group is a high-speed industrial belt feeder specifically designed for demanding applications in the cement, mining, and chemical industries. This feeder ensures precise and consistent gravimetric dosing with flow capacities up to 600 m³/h, maintaining dosing precision within ±0.5%. Its unique self-centering and adjustable tension system ensures even distribution of materials like clinker, urea fertilizer, and rubber granules. The GI GRAVIT integrates seamlessly into continuous production lines, offering automation support via SCMIII controllers for efficient operation and remote monitoring. Its robust construction features welded stringers for enhanced durability in harsh environments, and it’s available in three belt widths to meet diverse operational needs. For applications requiring corrosion resistance, customizable materials and configurations can be engineered, ensuring suitability across a range of high-temperature and abrasive material processes. Furthermore, maintenance is simplified with a quick belt change system, ensuring minimized downtime and reliable performance.

Benefits

- Maximizes material flow and productivity with robust high-speed operation.

- Ensures exceptional dosing accuracy, reducing waste and optimizing resource usage.

- Enhances safety and operational efficiency with fully enclosed, dust-reducing design.

- Reduces maintenance time with easily adjustable belt tension and quick change system.

- Customizable for various materials and production needs, ensuring flexible integration.

- Applications

- Polymers, Amino acids, Chemicals, Hydrometallurgy, Plastic pellets, Water treatment, Metals processing, Metals recycling, Additives, Minerals processing, Flue gas desulphurization, Technical ceramics, Specialty acids, Resins, Mining, Rubber, Fertilizers, Cement

- End products

- Rubber granules, Aluminium ingots, Polyethylene pellets, Epoxy resins, Urea fertilizer, Ammonium nitrate, Water treatment chemicals, Clinker, Alumina, Iron ore pellets, Phosphoric acid, Pvc compounds, Gypsum board, Lysine

- Steps before

- Grinding, Crushing, Mixing, Screening

- Steps after

- Packing, Conveying, Weighing, Storage

- Input ingredients

- clinker, gypsum, limestone, clay, anhydride, slag, shredded tyre waste, fruit shells, iron ore, pyrite, iron, alloys, coal bricks, calamine, metal pellets, chemicals, plastic pellets, additives, rubber, ash, mixtur, phengite, lime, urea, phosphates, phosphate rock, ammonium, ammonium sulphate, coke, limonite, graphite, calcined clay

- Output ingredients

- high flow rate granular materials, consistent gravimetric dosing materials, uniform distribution of materials

- Market info

- HASLER Group is known for manufacturing and supplying industrial engineered-to-order (ETO) equipment, specializing in mixing, filtration, and sealing solutions for various industries, with a reputation for quality and innovation in handling challenging process applications.

- Accuracy

- ±0.5%

- Flow Rate

- Up to 1, 100 m3/h

- Belt Width

- 1400 mm, 1600 mm, 1800 mm

- Material Flow Rate

- Up to 600 m3/h

- Operating Temperature

- -45°C to +200°C

- Dosing Type

- Gravimetric

- Automation

- SCMIII Controlled

- Construction

- Welded Stringers

- Belt Tension System

- Self-centring and Adjustable

- Options

- Chain Collector, Hammer Gate, Vibrating Inlet Hopper

- Batch vs. continuous operation

- Inline Continuous

- Flow rate capacity

- Up to 1, 100 m³/h

- Automation level

- PLC / Digital control

- Precision and consistency of flow

- ± 0.5%

- Material distribution system

- Self-centring and adjustable tension

- Modularity

- Customizable belt widths and lengths

- Ease of maintenance

- Quick belt change system

- Environmental Protection

- Fully enclosed system

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- High-temperature resistance

- Up to 200°C

- Agglomeration risk

- Yes

- Material type

- Granular and Powder

- Belt Width

- 1400 mm, 1600 mm, 1800 mm

- Belt Length

- Custom lengths

- Footprint

- Compact design for space efficiency

- Structure

- Welded stringers for durability

- Discharge Method

- Belt discharge with optional load-out breaker

- Inlet Hopper Options

- Vibrating, Extended, or Reinforced

- Material Cover

- Enclosed to reduce dust emission

- Special Belt

- High-temperature resistant conveyor belt

- Belt width

- 1400 mm, 1600 mm, 1800 mm

- Belt length

- Custom lengths

- Control system

- SCMIII controller

- Load-out breaker

- Optional

- Rod gate,plate gate

- Optional

- Material cover

- Optional

- Hammer gate

- Optional

- Vibrating inlet hopper

- Optional

- Inlet hopper type

- Extended or reinforced

- Special conveyor belt

- High-temperature resistant