Robotic dosing system for accurate micro quantities

Achieve precise and reproducible micro dosing of challenging raw materials in your production line with a robotic system designed for high throughput and continuous operation, ensuring safety and flexible formulation without manual weighing.

Performs Accurate Micro Dosing and Weighing

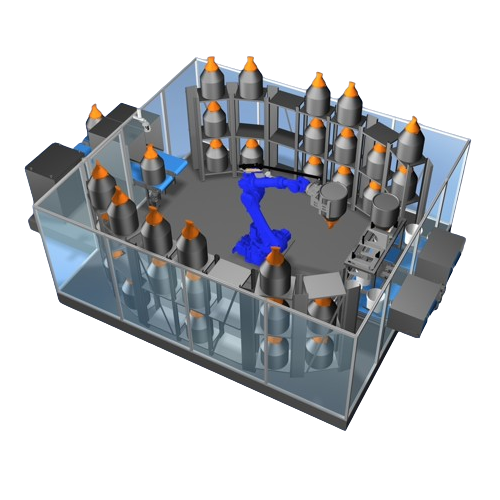

The AZO RoLog® from AZO GmbH & Co. KG is a robotic micro dosing system designed to enhance the precision and efficiency of automated batching in industrial settings. This innovative system replaces traditional manual weighing methods with a fully automated approach, handling micro quantities between 100 g to 5 kg with consistent reproducibility. It integrates seamlessly into production lines across the pharmaceutical, food, chemical, and plastics industries, catering to applications such as tablet coatings, protein supplements, and perfume compounds.

The system’s core advantage lies in its adaptability and modular structure, allowing easy expansion of raw material components. It operates around the clock, ensuring high throughput with continuous supply of raw materials and target containers, while minimizing operator exposure to hazardous materials through a shielded work environment. The AZO RoLog® supports flexible formulation management and batch traceability, optimizing operational efficiency and maintaining strict quality control.

Benefits

- Enhances operational efficiency with 24/7 automated production capabilities.

- Improves safety by isolating operators from critical raw materials.

- Ensures consistent quality with precise and reproducible dosing results.

- Offers scalability and adaptability through a modular design.

- Facilitates traceability and compliance with comprehensive batch tracking systems.

- Applications

- Food, Chemicals, Dyes, Active substances, Additives, Plastics, Pigments, Aromas, Pharmaceuticals

- End products

- Active ingredient formulations, Perfume compounds, Tablet coatings, Protein supplements, Capsule filling powders, Plastic masterbatches, Flavoring extracts, Vitamin premixes, Inkjet dyes, Food color blends

- Steps before

- Purification, Raw materials preparation, Emulsification, Drying, Grinding

- Steps after

- Further processing, Sterilization, Packing, Coating

- Input ingredients

- bulk solids, micro quantities, raw materials, pigments, dyes, aromas, additives, active substances

- Output ingredients

- dosed micro quantities, target containers, assembled batches

- Market info

- AZO is renowned for designing and manufacturing automated bulk material handling systems, specializing in mixer feeding, ingredient automation, and process control, known for their reliability and tailored solutions in the food, pharmaceuticals, and chemical industries.

- Accuracy

- Extremely accurate

- 100g to 5kg

- Automation

- Fully automated

- Batch size

- 100g to 5kg

- Continuous traceability

- Yes

- Tracking,tracing

- Modular Structure

- Yes

- Easy to upgrade

- Production

- 24/7 capability

- Safety Features

- Shielded work envelope

- Working mechanism

- Automated robotic dosing

- Batch vs. continuous operation

- Batch

- Automation level

- Fully automated with robot

- Flexibility

- Modular structure for easy upgrades

- Production capability

- 24/7 production

- Safety features

- Shielded work envelope with safety cage

- Cleaning method

- Manual

- Density/particle size

- 0.1–5 kg

- Industries served

- Pharmaceuticals, food, chemicals, plastics

- Dosing applications

- Pigments, dyes, aromas, additives, active substances

- Modular structure

- Yes

- Safety cage

- Enclosed

- Dosing range

- 100 g to 5 kg

- Work envelope

- Shielded

- Footprint

- Compact

- Integration into logistics system

- Standalone or fully integrated

- Modular structure

- Yes

- Variable raw materials capability

- Yes

- Flexible formulations

- Yes

- Shielded work envelope

- Yes