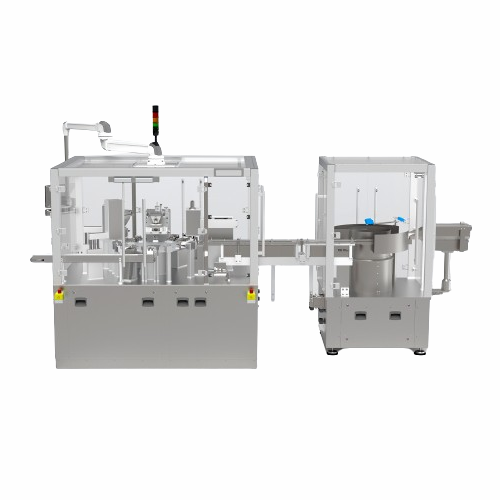

Rotary indexing table for dosing and assembly

Optimize production efficiency with a compact rotary indexing table that streamlines dosing, filling, and assembly processes, ensuring high-speed output and precise component handling for complex pharmaceutical and medical device manufacturing.

Facilitates Dosing and Assembly of Medical Devices

The FRT Rotary Indexing Dosing and Assembly Platform from Harro Höfliger is a compact, versatile solution ideal for pharmaceutical and medical device manufacturers. It efficiently handles dosing, filling, and assembly processes using precise rotary indexing technology. The FRT is adept at assembling inhalers, cartridges, and diagnostic products within a limited space, ensuring seamless integration into existing production lines.

Equipped with sophisticated dosing methods and control systems, the FRT supports both fully automatic and semi-automatic operations, achieving up to 60 cycles per minute across multiple lanes. Designed for high-speed operations, it offers compliance with cleanroom standards up to class A 100,000 – 100, making it suitable for sensitive environments.

The platform incorporates barrier technology for operator and product safety, especially when dealing with highly active and toxic substances. Available in various materials to ensure chemical compatibility and featuring integrated containment systems, the FRT meets rigorous industry standards such as GMP and FDA compliance.

Efficient parts handling, enabled by vacuums, grippers, or tongs, allows for accurate component transfer and assembly. Additionally, Harro Höfliger offers customization options and engineering support to tailor the system to specific production needs, ensuring optimal performance and integration.

Benefits

- Saves floor space with compact design, ideal for constrained areas.

- Enhances production speed with up to 60 cycles per minute.

- Ensures high precision in dosing and assembly to maintain product quality.

- Protects operators with integrated containment for handling toxic substances.

- Facilitates seamless production integration with easy connectivity to other systems.

- Applications

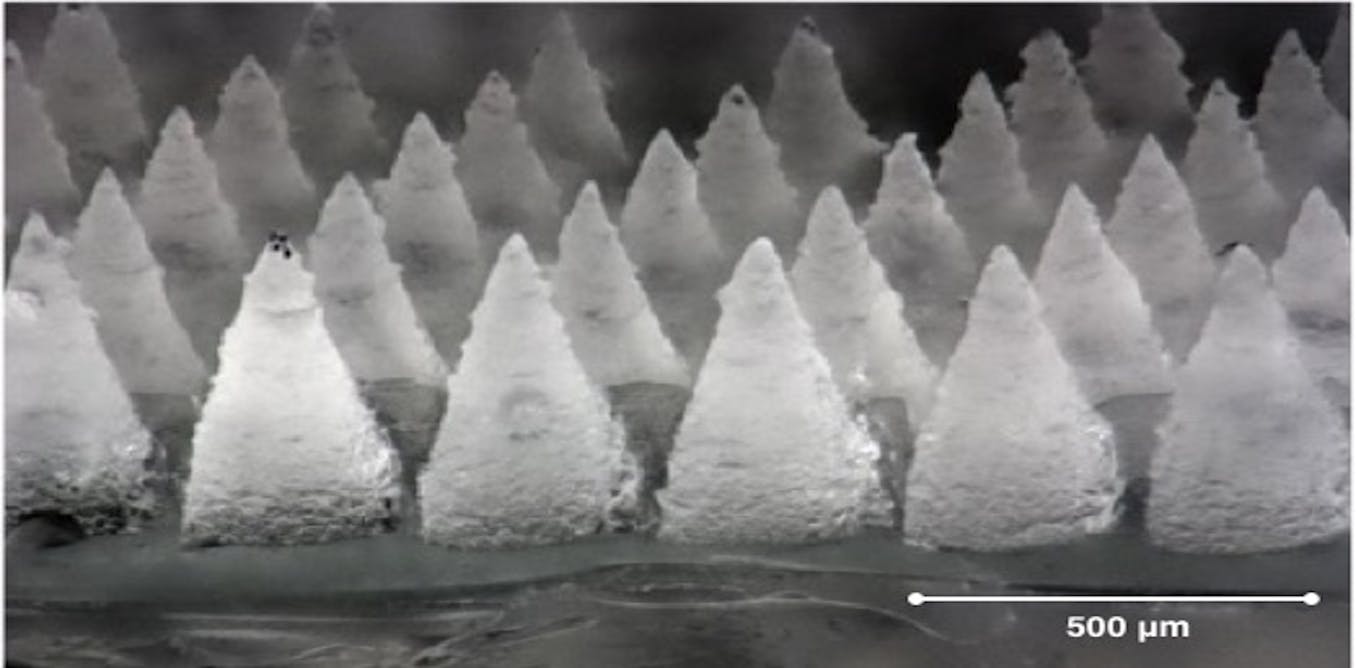

- Continence care, Inhalers, Inhalation products, Transdermal, Powder reservoirs, Skin care, Microneedles, Ostomy, Surgical sutures, Devices, Cartridges, Oral delivery systems, Medical, Diagnostic products, Pharmaceutical device assembly, Wound, Eye care

- End products

- Catheter systems, Adhesive wound dressings, Transdermal nicotine patches, Oral thin films, Nasal cannula tubes, Subdermal contraceptive implants, Disposable contact lenses, Drug-eluting microneedles, Sutures for skin closure, Ophthalmic solutions, Colostomy bags, Insulin cartridges, Nasal spray cartridges, Asthma inhalers, Dry powder inhalers

- Steps before

- Ingredient Preparation, Component Sorting

- Steps after

- Product Quality Inspection, Packing, Labeling

- Input ingredients

- powder, solids, liquids, components

- Output ingredients

- inhalers, devices, cartridges, powder reservoirs

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- up to 60 cycles / minute

- Version

- 1 to 12 lanes

- Cleanroom version

- cleanroom class up to A 100, 000 - 100

- Working mechanism

- Rotary indexing

- Automation level

- Fully automatic / Semi-automatic

- Batch vs. continuous operation

- Batch

- Changeover time

- Minimal

- CIP/SIP

- Integrated containment

- Cleaning method

- Operator protection

- Compactness

- Space-saving

- Integrated steps

- Dosing and verification

- Ergonomic design

- Operator-friendly

- Production speed

- Up to 60 cycles/minute

- Biological compatibility

- Sterile / Non-toxic

- Cleanability

- CIP / SIP compatible

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Requires little space

- Machine footprint

- Integrated dosing and compact arrangement

- Discharge method

- Automatic with vacs, grippers, or tongs

- Control panel type

- Integrated control systems

- Number of lanes

- 1 to 12 lanes

- Cleanroom version

- Up to cleanroom class A

- Output cycles

- Up to 60 cycles/minute

- Control panel type

- HMI or digital interface

- Integration possibilities

- Easy linking with technology platforms and packaging machines

- Footprint

- Compact and space-saving design

- Turret configuration

- 1 to several turrets

- Operation version

- Fully automatic or semi-automatic

- Manual workstation integration

- Yes

- Cleanroom version availability

- Up to cleanroom class A

- Containment features

- Integrated containment for operator protection