Syringe dispensing system for nuclear medicine

Optimize your radiopharmaceutical workflows with a system designed to precisely dispense and fractionate single-dose syringes, ensuring sterility and accurate radioactivity levels while reducing operator exposure to radiation.

Dispenses and Fractions Radiopharmaceuticals Precisely

The TIMO 2 Syringe Dispensing System from COMECER is a semi-automatic solution designed to enhance the precision and efficiency of radiopharmaceutical dispensing. This equipment specifically targets the challenges faced by nuclear medicine departments and radiopharmaceutical manufacturers, offering accurate fractionation of radiopharmaceuticals including PET and SPECT isotopes. Its compact design allows for installation within shielded laminar flow isolators, ensuring sterility and safety standards are met. The system includes a dual-channel peristaltic pump for controlled filling, enabling precise dosing essential for therapeutic applications. Automation is achieved through an intuitive operator interface, compliant with cGAMP regulations, while integrated management software facilitates real-time monitoring and activity calibration. The TIMO 2 supports integration into existing workflows, with features like batch management, syringe tracking, and compliance with cGMP standards. Its design minimizes operator radiation exposure during dosage setup, and the sturdy, portable build allows for easy maintenance and relocation within laboratory environments. Additionally, COMECER offers customization options and detailed engineering support, ensuring the TIMO 2 meets specific operational requirements.

Benefits

- Ensures precise dosage delivery, enhancing patient safety and treatment efficacy.

- Lowers operator radiation exposure, promoting a safer work environment.

- Integrates seamlessly into existing workflows, improving operational efficiency.

- Supports sterile preparation within shielded environments, ensuring compliance with safety standards.

- Facilitates rapid batch management, optimizing overall throughput and productivity.

- Applications

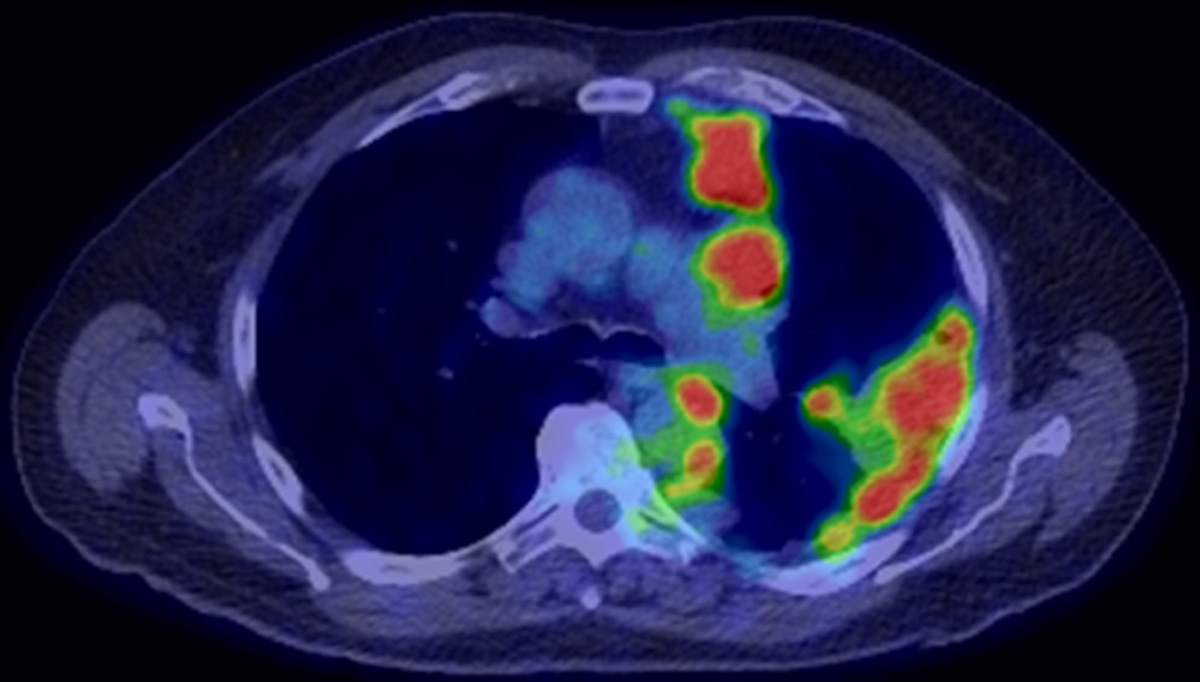

- Radiotherapy drugs, Spect isotopes, Radiopharmaceuticals, Pet isotopes

- End products

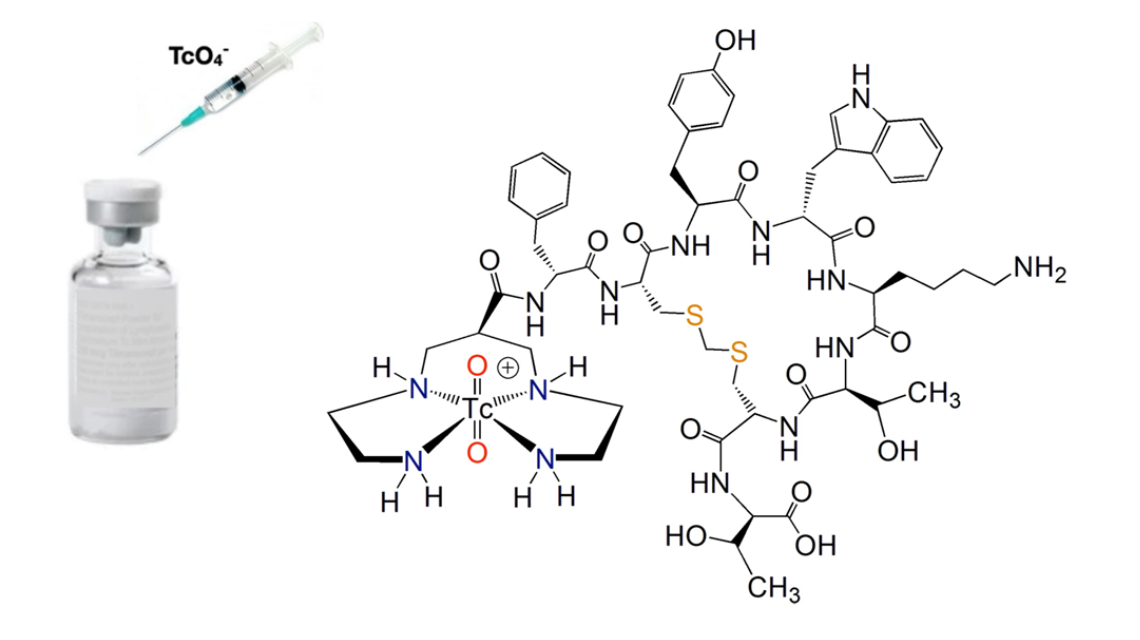

- Gallium-68 generators, Iodine-123 radiopharmaceuticals, Technetium-99m radiopharmaceuticals, Lutetium-177 radiopharmaceuticals, Fluorodeoxyglucose (fdg)

- Steps before

- Radiopharmaceutical synthesis, Mother vial preparation

- Steps after

- Sterile transport, Dose administration

- Input ingredients

- radiopharmaceutical mother vial, PET isotopes, SPECT isotopes, saline solution

- Output ingredients

- single-dose syringes, filled syringes, sterile radiopharmaceutical preparations

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Size

- Compact

- Ergonomics

- High

- Fractionation

- Semi-automatic

- Dispensing System

- Semi-automatic filling

- Software Compliance

- cGAMP compliant

- Sterility

- Ensured in shielded laminar flow isolator

- Filling System

- Two-channel peristaltic pump

- Control Panel

- PC control panel

- Data Storage

- cGMP and GAMP Standards compliant

- Activity Management

- Real-time monitoring

- Transport Safety

- Safe transport from radioprotection point of view

- Weight

- Reduced weight

- Portability

- Carrying handle provided

- Automation level

- Semi-automatic

- Batch vs. continuous operation

- Batch

- Recipe management

- cGAMP compliant

- Syringe fractionation method

- External mother vial/Radiopharmaceutical synthesis module

- Real-time monitor

- PC control panel

- Installation location

- Shielded laminar flow isolator

- Exposure reduction

- Significant reduction of operator dose

- Cleaning and Maintenance

- Easily removable for cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- PC control panel

- Discharge method

- Closed syringes for transport

- Control panel type

- PC control panel

- Integration possibilities

- Compatible with shielded laminar flow isolators

- Software

- Recipe management and workflow control software